An acoustic emission crack monitoring method and system

A technology of acoustic emission and acoustic emission sensor, which is applied in the direction of using acoustic emission technology for material analysis, processing detection response signals, etc., and can solve problems such as no effective and feasible methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in more detail below in conjunction with the accompanying drawings.

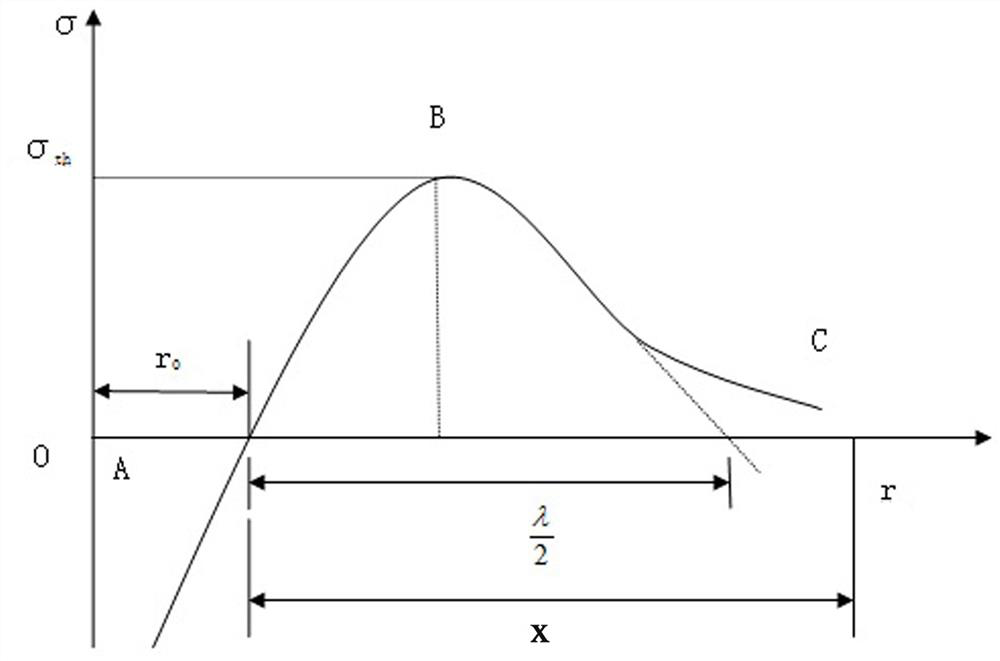

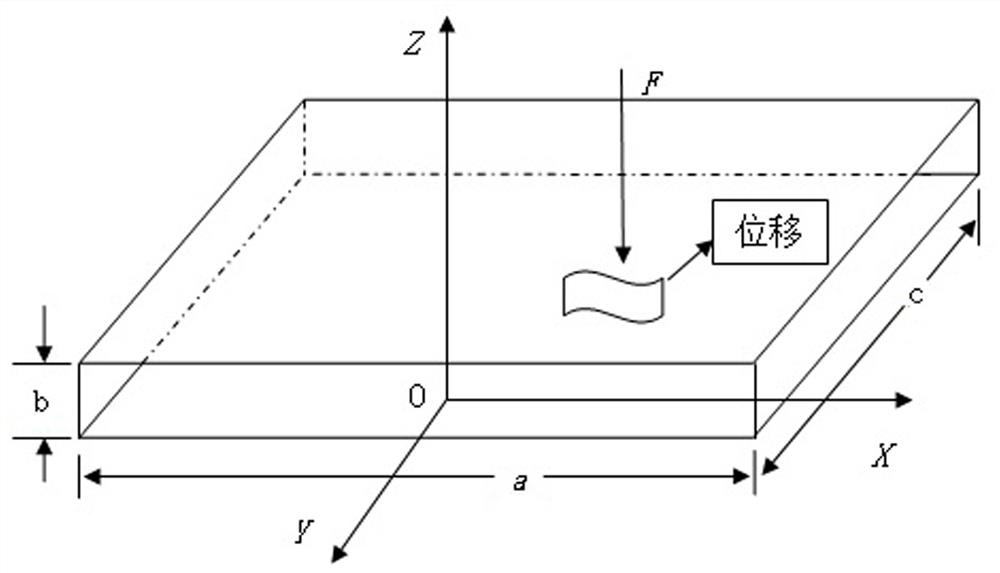

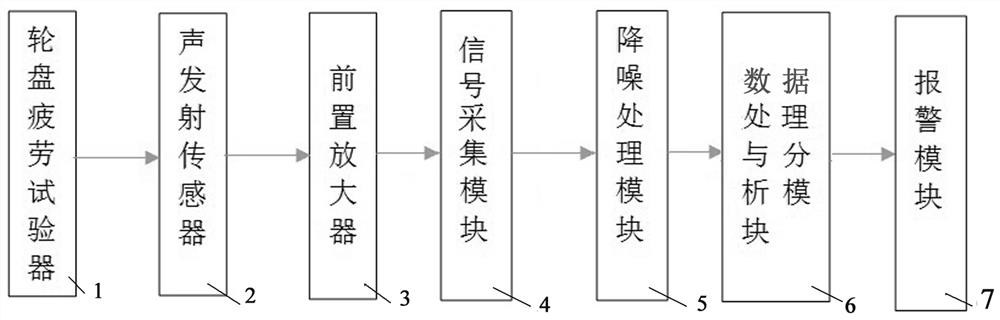

[0036] Almost all materials produce acoustic emission signals during deformation and fracture, and the acoustic emission signals are the source information of the fatigue cracks of the wheel disk. Therefore, based on the principle of acoustic emission, the online acoustic emission monitoring research on the low cycle fatigue cracks of the wheel disk is proposed. Wheel disc fatigue is a process in which dislocations, slips, and microscopic cracks develop into macroscopic cracks in the wheel disc material. When dislocations, slips, and microscopic cracks are generated, stress waves are generated at the same time, and the stress waves become more and more severe as the cracks grow. Strong, the acoustic emission sensor is used to pick up the stress wave signal and analyze and process it.

[0037] Acoustic emission detection technology can capture the occurrence and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com