Optical system, camera module and electronic equipment

A technology of optical system and optical axis, applied in the direction of optics, optical components, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

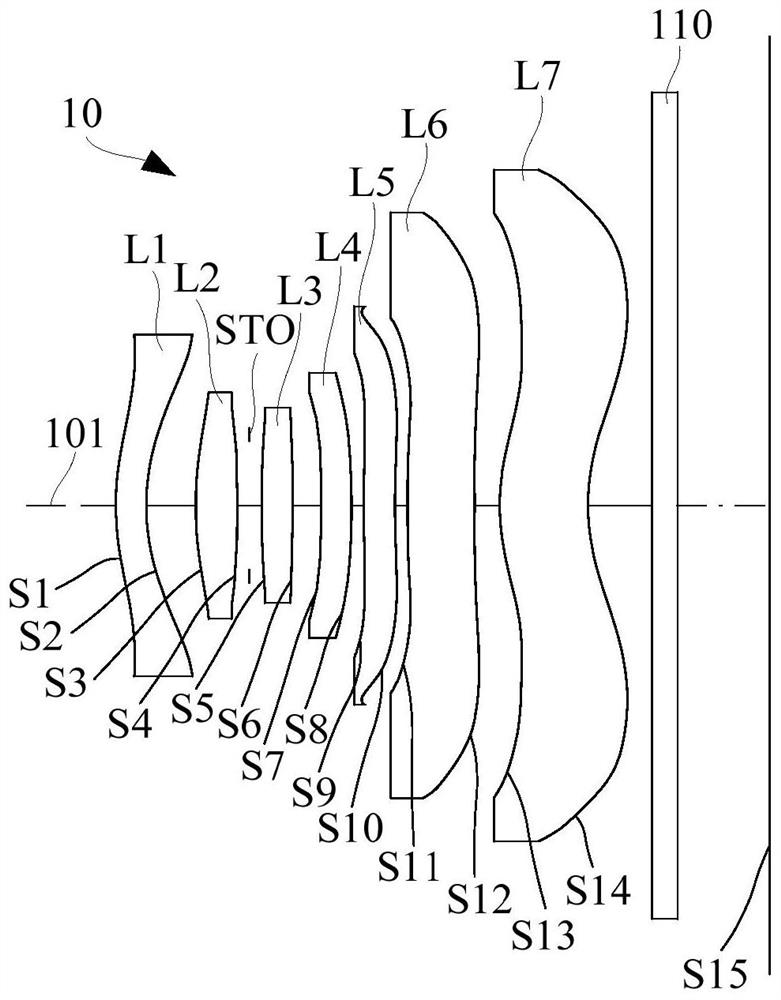

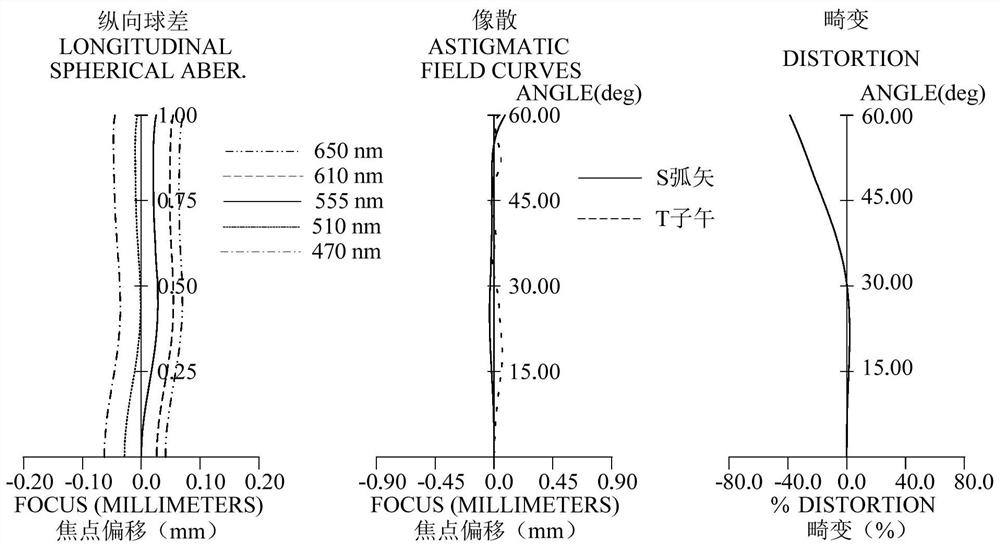

[0079] refer to figure 1 , in the first embodiment, the optical system 10 includes a first lens L1 with negative refractive power, a second lens L2 with positive refractive power, an aperture stop STO, and a lens with positive refractive power from the object side to the image side along the optical axis 101. The third lens L3 with a refractive power, the fourth lens L4 with a positive refractive power, the fifth lens L5 with a negative refractive power, the sixth lens L6 with a positive refractive power, and the seventh lens L7 with a negative refractive power. Each lens surface type of optical system 10 is as follows:

[0080] The object side S1 of the first lens L1 is convex at the near optical axis, and the image side S2 is concave at the near optical axis; the object side S1 is convex near the maximum effective aperture, and the image side S2 is concave near the maximum effective aperture .

[0081] The object side S3 of the second lens L2 is convex at the near optical ...

no. 2 example

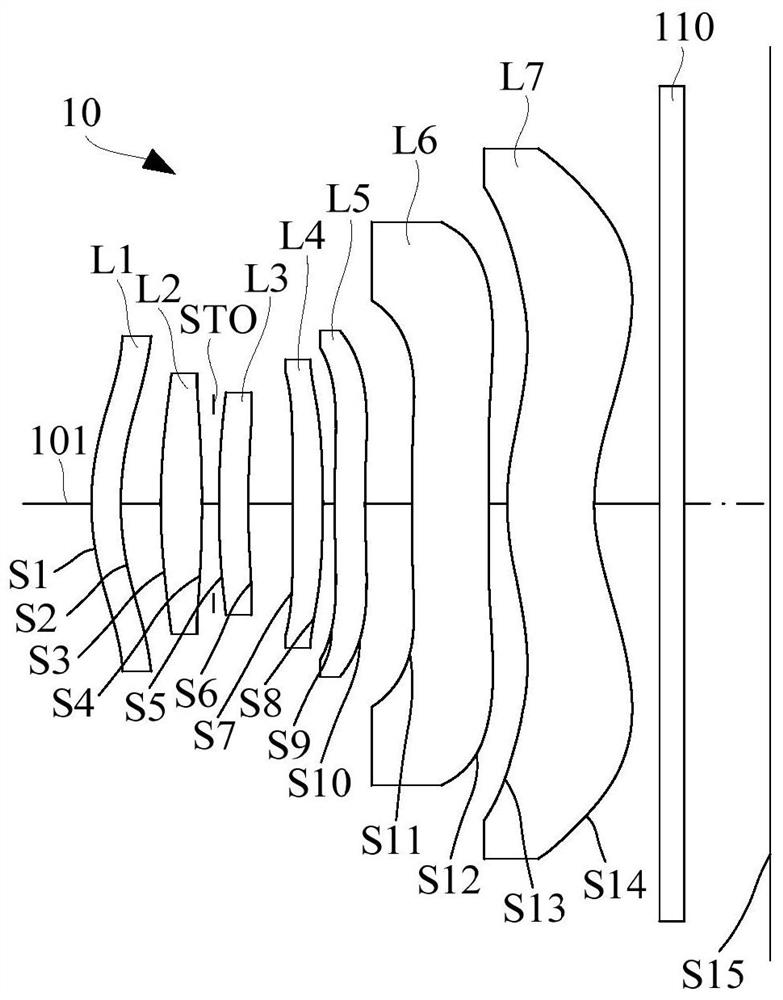

[0108] refer to image 3 , in the second embodiment, the optical system 10 includes a first lens L1 with positive refractive power, a second lens L2 with positive refractive power, an aperture stop STO, and a lens with negative refractive power along the optical axis 101 from the object side to the image side. The third lens L3 with a refractive power, the fourth lens L4 with a positive refractive power, the fifth lens L5 with a negative refractive power, the sixth lens L6 with a positive refractive power, and the seventh lens L7 with a negative refractive power. Each lens surface type of optical system 10 is as follows:

[0109] The object side S1 of the first lens L1 is convex at the near optical axis, and the image side S2 is concave at the near optical axis; the object side S1 is convex near the maximum effective aperture, and the image side S2 is concave near the maximum effective aperture .

[0110] The object side S3 of the second lens L2 is convex at the near optical...

no. 3 example

[0126] refer to Figure 5 , in the third embodiment, the optical system 10 includes a first lens L1 with negative refractive power, a second lens L2 with positive refractive power, an aperture stop STO, and a lens with positive refractive power from the object side to the image side along the optical axis 101. The third lens L3 with a refractive power, the fourth lens L4 with a positive refractive power, the fifth lens L5 with a negative refractive power, the sixth lens L6 with a positive refractive power, and the seventh lens L7 with a negative refractive power. Each lens surface type of optical system 10 is as follows:

[0127] The object side S1 of the first lens L1 is convex at the near optical axis, and the image side S2 is concave at the near optical axis; the object side S1 is convex near the maximum effective aperture, and the image side S2 is concave near the maximum effective aperture .

[0128] The object side S3 of the second lens L2 is convex at the near optical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective focal length | aaaaa | aaaaa |

| Optical length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com