Optical imaging lens, camera shooting module, electronic equipment and automobile

An optical imaging lens and camera module technology, applied in optics, optical components, instruments, etc., can solve the problem that the presentation of long-distance details and the clear imaging of a large angle range cannot be satisfied at the same time, the depth of field range is small, and the resolution of the front-view camera lens can not be satisfied. low rate issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

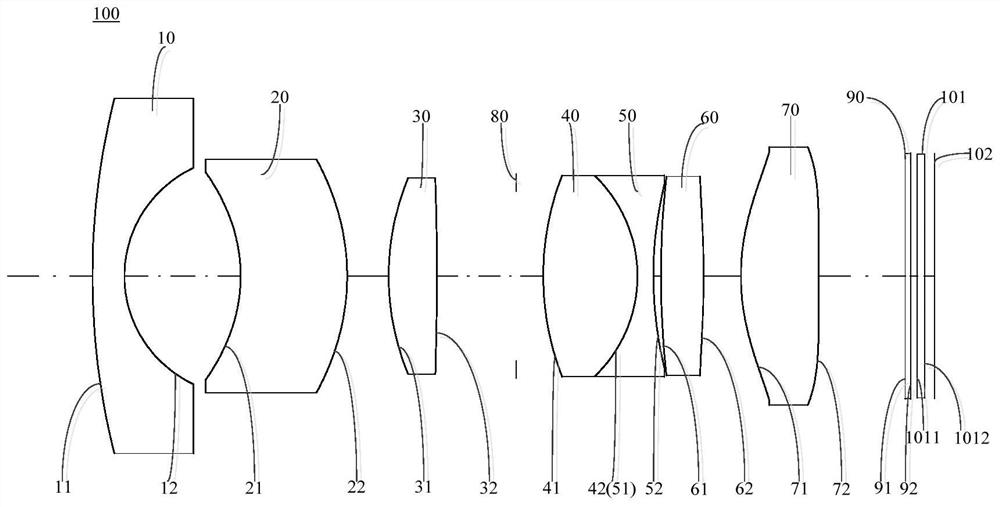

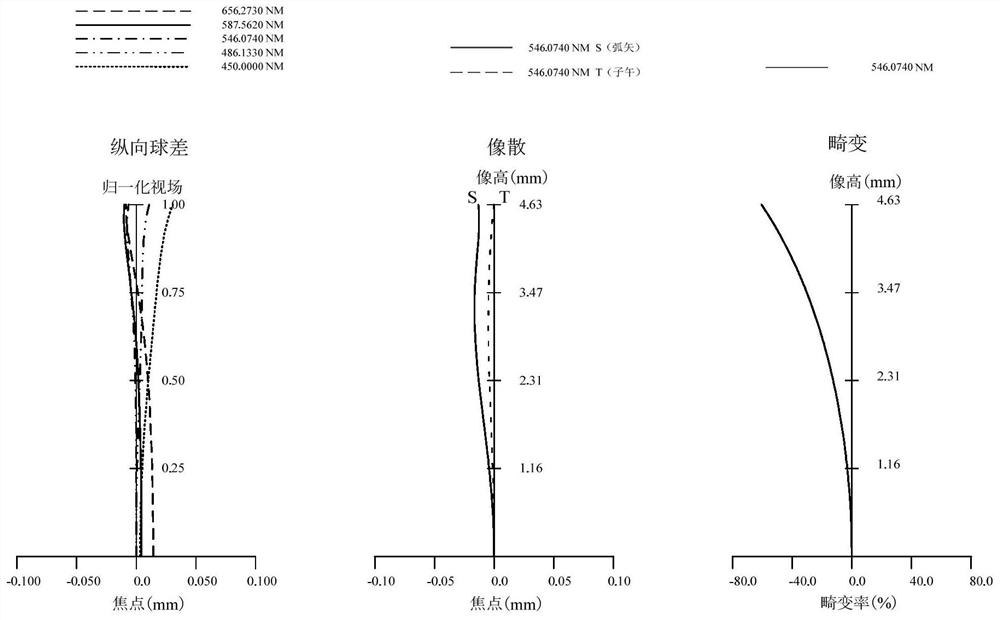

[0067] see figure 1 with figure 2 As shown, according to Embodiment 1 of the present application, an optical imaging lens 100 is provided, and the optical imaging lens 100 includes a first lens 10, a second lens 20, a third lens 30, The fourth lens 40 , the fifth lens 50 , the sixth lens 60 , and the seventh lens 70 .

[0068] Wherein, the first lens 10 has a negative refractive power, the object side 11 of the first lens 10 is a convex surface in the near optical axis region, and the image side 12 of the first lens 10 is a concave surface in the near optical axis region;

[0069] The second lens 20 has a negative refractive power, the object side 21 of the second lens 20 is concave in the near optical axis region, and the image side 22 of the second lens 20 is convex in the near optical axis region;

[0070] The third lens 30 has a positive refractive power, the object side 31 of the third lens 30 is convex in the near optical axis region, and the image side 32 of the thir...

Embodiment 2

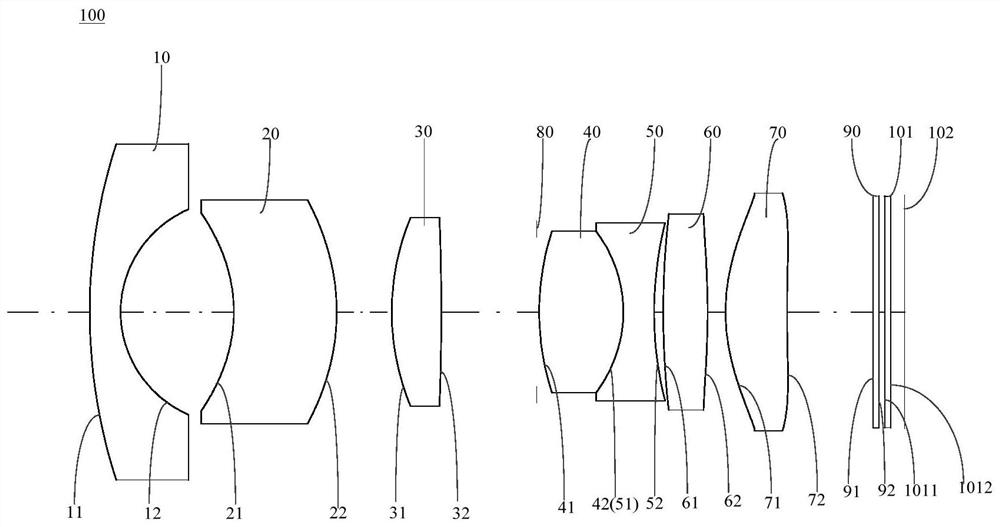

[0099] see image 3 with Figure 4 As shown, according to Embodiment 2 of the present application, an optical imaging lens 100 is provided. The structure of the optical imaging lens 100 is the same as that in Embodiment 1. The difference is that the optical imaging lens 100 in this embodiment satisfies The following conditional expression:

[0100] -20

[0101] -18.5<∑f123 / f=-18.512<-12.5;

[0102] 1.5<|Rs61-Rs62| / |Rs61+Rs62|=24.677<40;

[0103] -27.5

[0104] 51(° / mm)

[0105] 1.5

[0106] 2.5

[0107] 3.3

[0108] Wherein, the above-mentioned parameters have been defined before, and will not be repeated here.

[0109] Table 3 is a characteristic table of the optical imaging lens 100 of this embodiment, wherein each data is obtained using visible light with a reference wavelength of 546.074nm, and the units of Y radius, thickness, and focal length are...

Embodiment 3

[0118] see Figure 5 with Image 6 As shown, according to Embodiment 3 of the present application, an optical imaging lens 100 is provided. The structure of the optical imaging lens 100 is the same as that in Embodiment 1. The difference is that the optical imaging lens 100 in this embodiment satisfies The following conditional expression:

[0119] -20

[0120] -18.5<∑f123 / f=-12.702<-12.5;

[0121] 1.5<|Rs61-Rs62| / |Rs61+Rs62|=1.512<40;

[0122] -27.5

[0123] 51(° / mm)

[0124] 1.5

[0125] 2.5

[0126] 3.3

[0127] Wherein, the above-mentioned parameters have been defined before, and will not be repeated here.

[0128] Table 5 is a characteristic table of the optical imaging lens 100 of this embodiment, wherein each data is obtained by using visible light with a reference wavelength of 546.074nm, and the units of Y radius, thickness and focal length ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com