Control method and device of engine system and engine system

An engine system and control method technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve problems such as failure to timely reflect the lubrication state of the supercharger, engine fire, and large fault detection errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

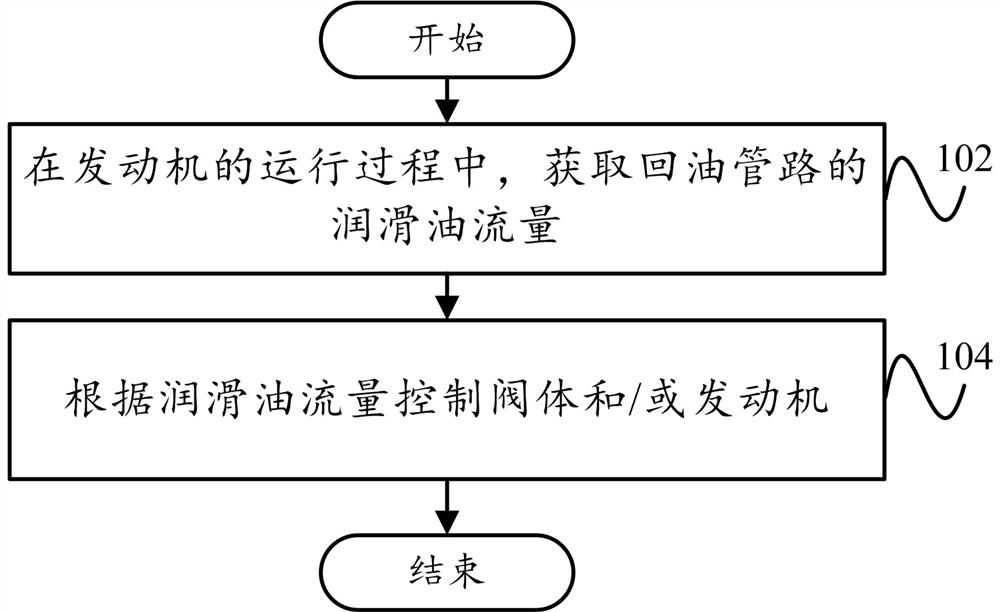

[0049] like figure 1 As shown, according to the first aspect of the present invention, a control method of an engine system is proposed, including:

[0050] Step 102, during the operation of the engine, acquire the lubricating oil flow of the oil return line;

[0051] Step 104 Control the valve body and / or the engine according to the lubricating oil flow.

[0052] In this embodiment, since there is an abnormal wear in the supercharger bearing, such as the supercharger bearing, the supercharger is broken and the supercharger sealing ring is faded, and the amount of lubricating oil through the supercharger will be much greater than The amount of lubrication during normal operation. To this end, during the operation of the engine, the fluid flow rate of the engine system oil supply line is periodically acquired, determined whether or not the pressurizer has failed according to the lubricant flow, and adjusts the valve body and / or engine in the event of a failure. Thereby reducing...

Embodiment 2

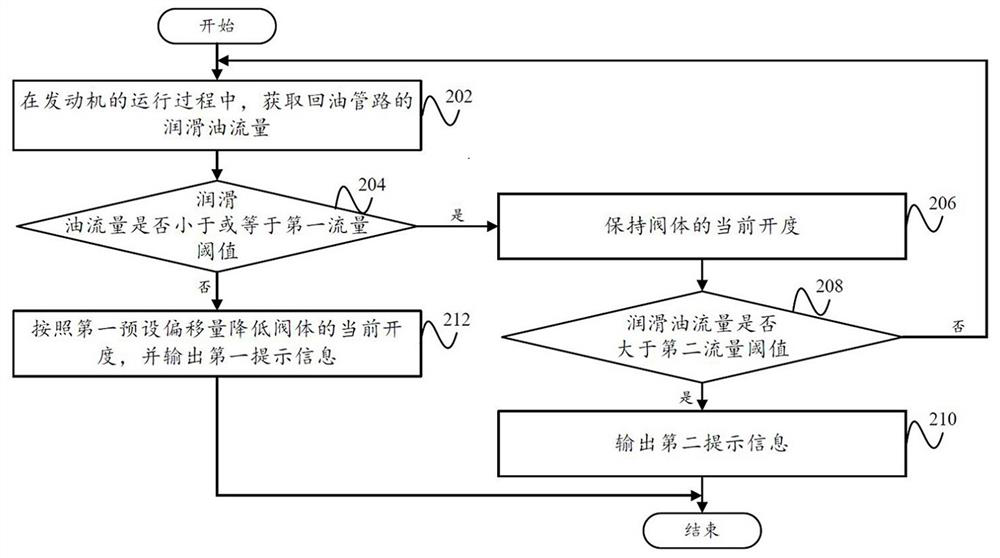

[0055] like figure 2 As shown, in accordance with an embodiment of the present invention, a control method of an engine system is proposed, including:

[0056] Step 202, during the operation of the engine, acquire the lubricating oil flow of the oil return line;

[0057] Step 204: Whether the lubricating oil flow is less than or equal to the first flow threshold, if yes, enter step 206, if, proceed to step 212;

[0058] Step 206: Keep the current opening degree of the valve body;

[0059] Step 208, whether the lubricating oil flow is greater than the second flow threshold, and if yes, the process proceeds to step 210, if, proceeds to step 202;

[0060] Step 210 output the second prompt information;

[0061] Step 212, reduce the current opening degree of the valve body according to the first preset offset, and output the first prompt information.

[0062] Wherein, the first flow rate threshold is greater than the second flow rate threshold.

[0063] In this embodiment, during the o...

Embodiment 3

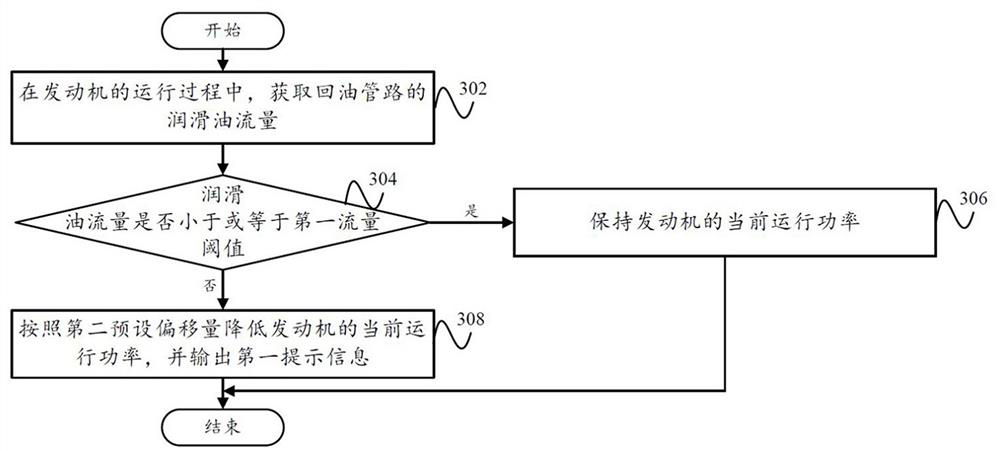

[0069] like image 3As shown, in accordance with an embodiment of the present invention, a control method of an engine system is proposed, including:

[0070] Step 302, during the operation of the engine, acquire the lubricant flow of the oil return line;

[0071] Step 304: Whether the lubricating oil flow is less than or equal to the first flow rate threshold, if yes, enter step 306, if, enter step 308;

[0072] Step 306, keep the current operating power of the engine;

[0073] Step 308, reduce the current run power of the engine according to the second preset offset, and output the first prompt information.

[0074] In this embodiment, during operation of the engine, the current operation power of the engine can also be adjusted according to the size relationship between the lubricating oil flow and the first flow threshold, and then adjust the flow of lubricating oil from the engine into the supercharger. .

[0075] Specifically, in the case where the lubricating oil flow is les...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com