Grounding protection explosion-proof plug

A grounding protection and explosion-proof technology, which is applied to the protective grounding/shielding device of connecting parts, connections, and parts of connecting devices, etc., can solve the problems of unstable grounding and grounding, difficult to achieve in small spaces, etc., and reduce contact resistance. , the effect of improving convenience and stability, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

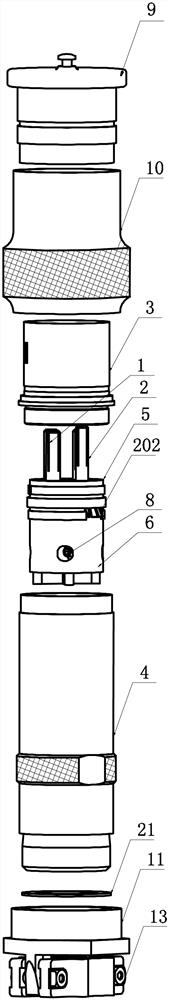

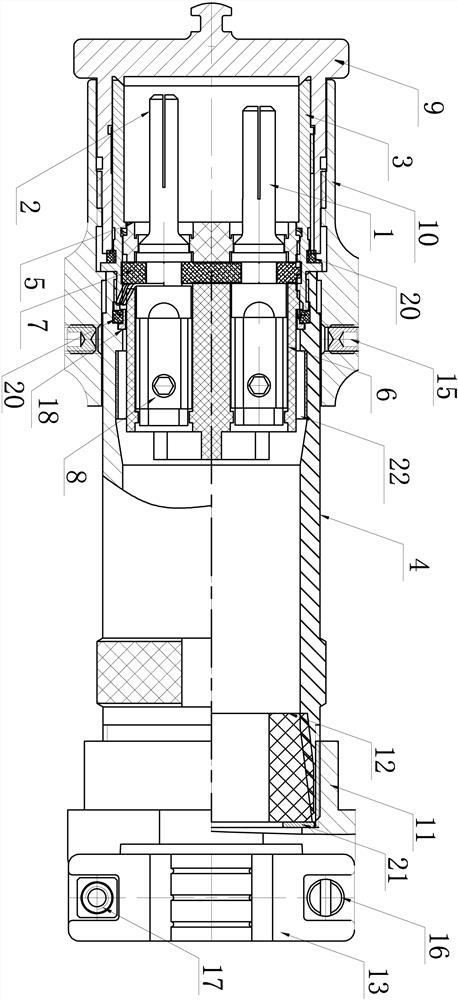

[0064] Such as Figure 1~Figure 15 As shown, the grounding protection flameproof plug includes a middle-pass shell assembly, the shell assembly is provided with a base assembly, and the shell assembly includes an upper shell 3 and a lower shell 4 that can be combined with each other; and the embedded One end of the upper shell 3 and the lower shell 4 provided with the mounting seat can be socketed and combined.

[0065] Specifically, such as figure 1 , figure 2 , Figure 11 , Figure 12As shown, the upper casing 3 is a circular tube shell, the top inside of the upper part of the upper casing 3 is provided with an inner slope surface 301, and the upper surface of the casing is provided with a long convex key 302, and the long convex key 302 is connected with the upper casing. An annular groove 1 304 is arranged between the annular bosses 1 303 of the body 3 for placing the sealing outer ring 20, and an inner boss 305 and an annular groove 2 306 are respectively arranged in...

Embodiment 2

[0077] A method for preparing and assembling a grounding protective flameproof plug, comprising the following steps:

[0078] Step one, the assembly of the base assembly.

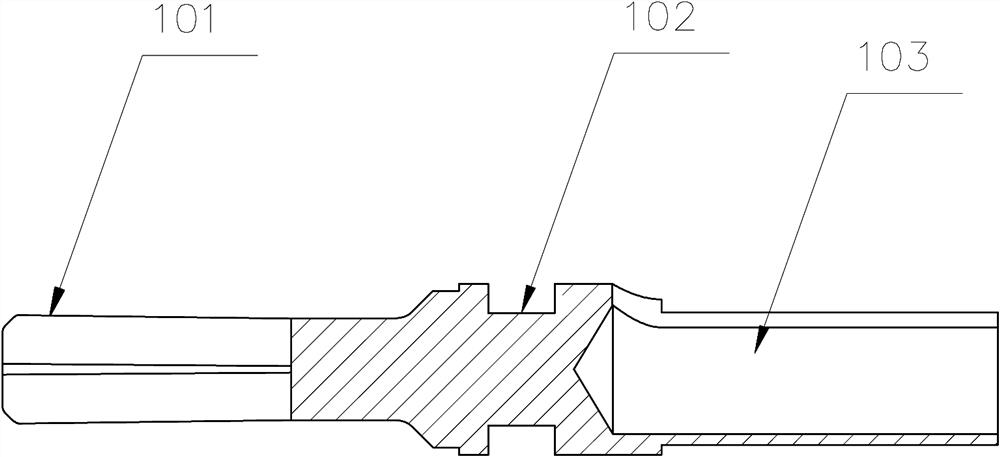

[0079] The grounding pin assembly 2 is formed by welding the grounding pin 201 and the grounding reed 202; several butt joint pins 1 and the grounding pin assembly 2 are respectively equipped with crimping terminals 8 to form a crimping joint. The joint part is fixedly combined with the mounting seat to form a base joint part.

[0080] Further, specifically, the mounting ring grooves on both sides of the ring groove 4 of the docking pin 1 and the grounding pin assembly 2 cooperate with the upper end surface and the lower end surface of the rubber base 7 respectively to clamp and limit, and the upper base 5. Load it from the top of the docking pin 1 and the grounding pin assembly 2. The lower end surface of the upper base 5 is matched with the upper end surface of the rubber base 7. The lower base 6 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com