A lifting platform for underwater operation

A technology of underwater operation and lifting platform, which is applied in the direction of underwater operation equipment, lifting devices, ships, etc., and can solve the problems of inability to meet the requirements of safe operation in harsh underwater environments, poor coordination and stability, and small loads , to achieve the effect of improving the flexibility of use, a wide range of use, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

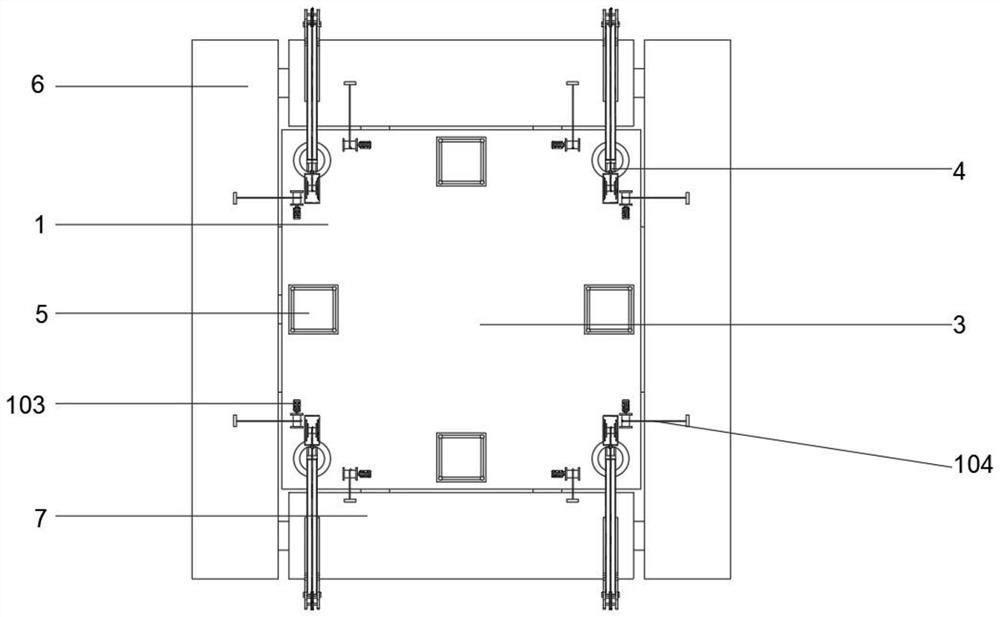

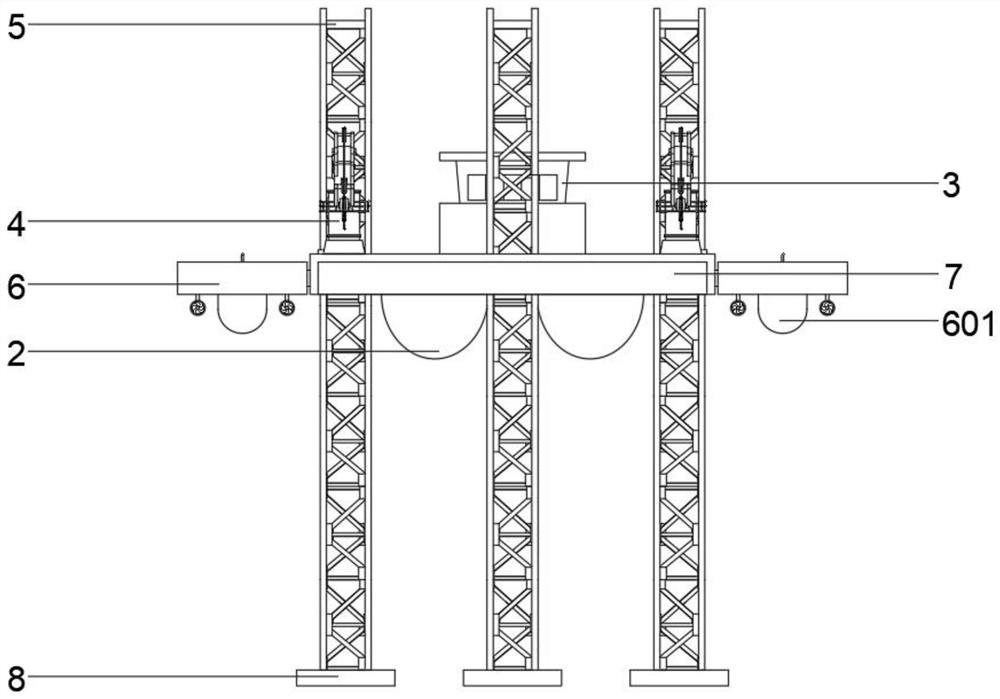

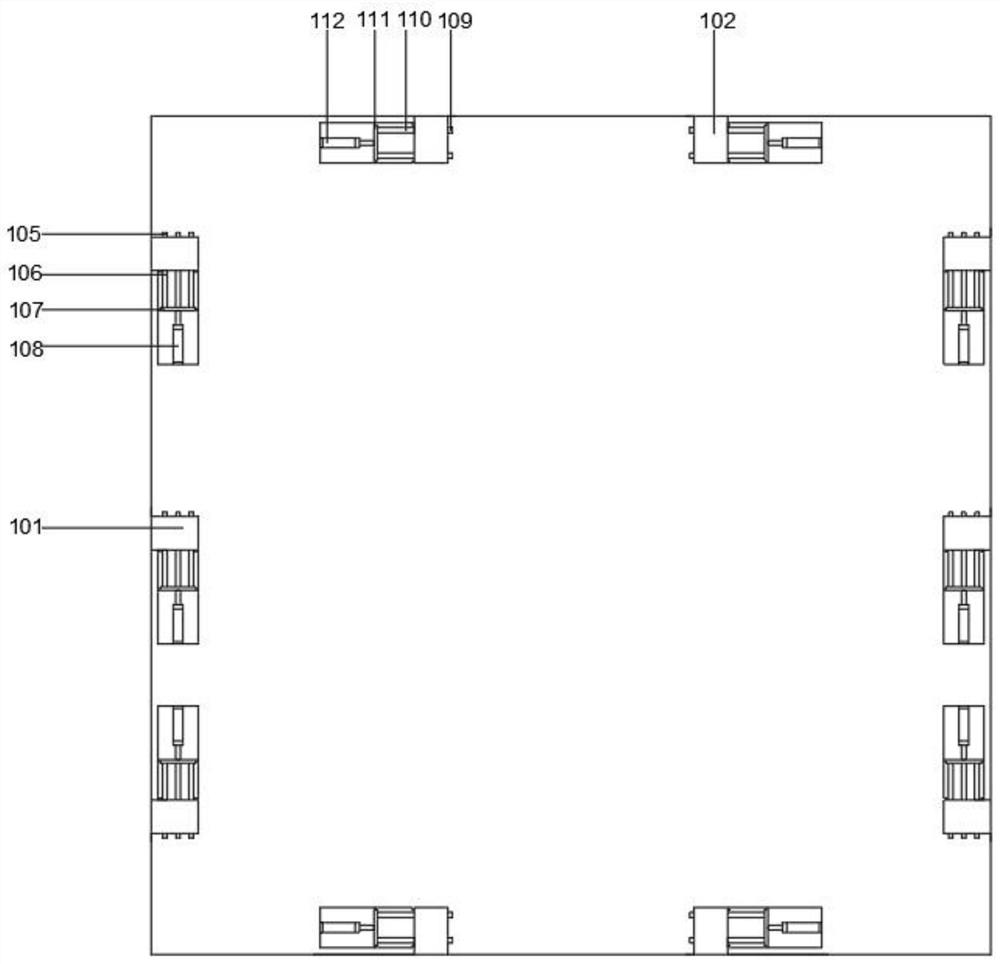

[0041] Example 1: Only the first lifting plate 6 is used for underwater operations, the first push plate 107 is controlled to retract the first insertion bolt 106, so that the rigid connection between the first lifting plate 6 and the main deck 1 is released, and then the second sea valve 602 Partially open, so that the external water flows into the two ballast tanks 601, and at the same time, the two slewing cranes 4 corresponding to the first lifting plate 6 of the operation slowly release the slings 407 to cooperate with the first lifting plate 6 to sink , by controlling the water inflow of the two ballast tanks 601 and the length of the sling 407 of the slewing crane 4 to control and adjust the hovering depth of the first lifting plate 6 in the water, so as to realize the flexible control of the depth of the first lifting plate 6. After the lifting plate 6 completes the underwater operation, the second compressed air storage tank 605 enters the compressed air into the balla...

Embodiment 2

[0042] Example 2: Two first lifting plates 6 are used for underwater operation at the same time, the first docking blocks 611 of the two first lifting plates 6 are released from the first docking groove 101 in the main deck 1, and the two first lifting plates 6 are lifted and lowered. The board 6 is disconnected from the main deck 1, and then the ballast tanks 601 of the two first lifting boards 6 enter the water through the second sea valve 602 to drive the first lifting board 6 to sink slowly, and at the same time, the slewing crane 4 releases the slings 407 to cooperate The first lifting plate 6 sinks, and the two first lifting plates 6 can sink to the same water depth or respectively to different water depths for simultaneous operation, and the electric propeller 609 arranged at the bottom of the first lifting plate 6 during underwater operation After the operation, the posture and position of the first lifting plate 6 in the water can be adjusted appropriately. After the o...

Embodiment 3

[0043] Example 3: Only use the second lifting plate 6 for underwater operations, control the second hydraulic push rod 112 to retract the second insertion bolt 110, so that the first lifting plate 7 is released from the rigid connection with the main deck 1, and the first lifting plate 7 of the operation is released. The two slewing cranes 4 corresponding to the two lifting boards 7 slowly release the slings 407, and cooperate with the second lifting board 7 to sink. By controlling the length of the slings 407 of the slewing crane 4, the suspension of the second lifting board 7 in the water is controlled and adjusted. Depth, in order to realize flexible control of the depth of the second lifting plate 7, when the second lifting plate 7 completes the underwater operation, the two slewing cranes 4 recover the slings 407, the second lifting plate 7 slowly rises to the water surface, and then the second lifting The plate 7 inserts the second docking block 705 into the second dockin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com