Split rotary type belt carrier roller bracket

A roller bracket, rotating technology, applied in the direction of rollers, conveyor objects, transportation and packaging, etc., can solve the problems of high work intensity, time-consuming and laborious, etc., and achieve the effect of easy and rapid replacement of rollers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

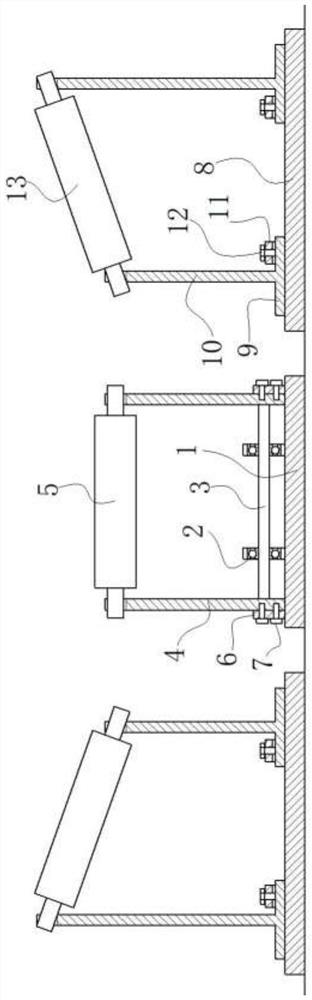

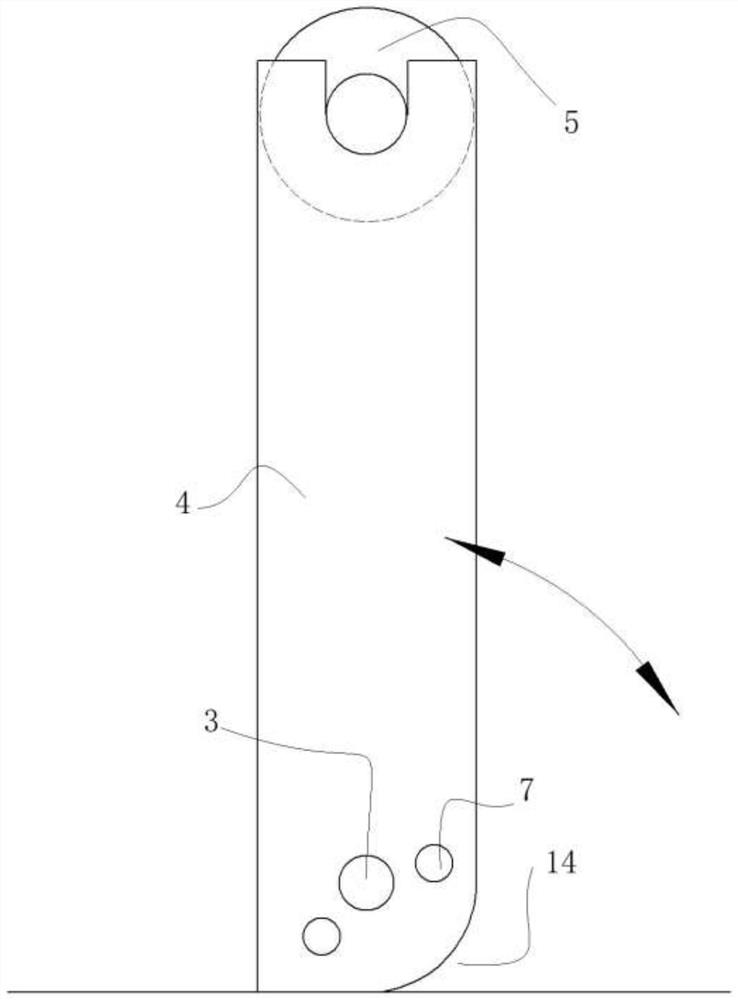

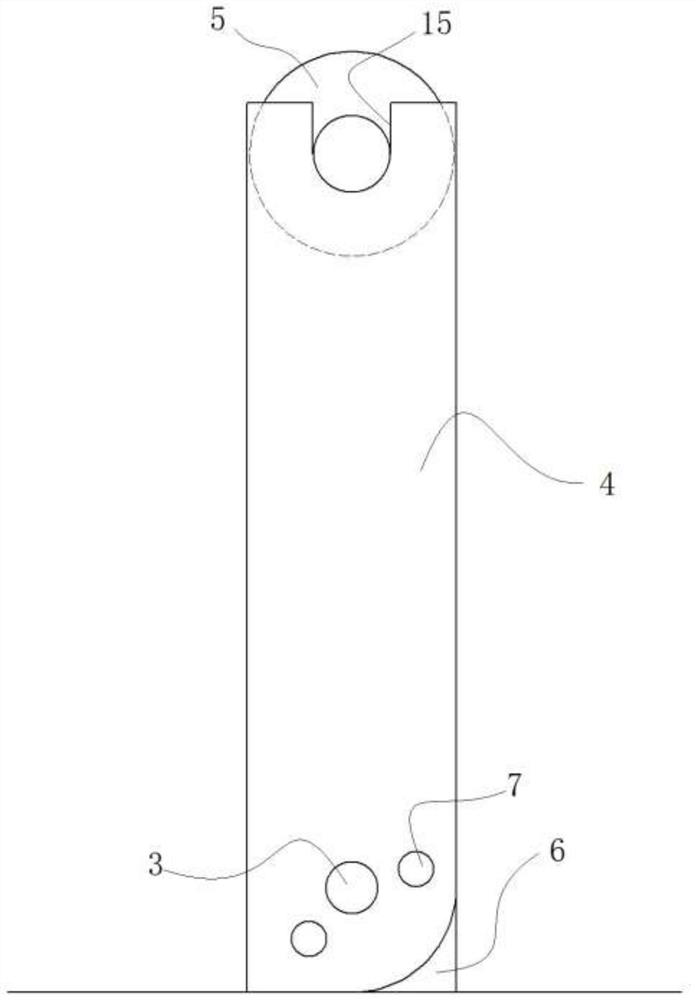

[0023] Such as figure 1 As shown, the split rotary belt idler bracket includes a horizontal idler assembly in the middle and inclined idler assemblies on both sides. The horizontal idler assembly includes a first base 1, a first bracket and a first roller 5 , the lower end of the first bracket is hinged to the first base 1 , and the first rotating roller 5 is arranged on the upper end of the first bracket.

[0024] The inclined roller assembly includes a second base 8, a second bracket and a second roller 13, the lower end of the second bracket is detachably fixed to the second base 8, and the upper end of the second bracket is set The second turning roller 13 .

[0025] When replacing the idler rollers in this scheme, first disassemble the inclined idler assembly from both sides, and then the inclined idler assembly on both sides can be directly replaced. Secondly, when the horizontal idler assembly in the middle is needed, the lower end of the horizontal first bracket Base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com