Fixation structure for power socket of medical trolley

A technology of power socket and fixed structure, which is applied in the field of medical devices, can solve the problems of unfavorable industrialized mass production and inability to operate large-scale assembly lines, etc., and achieve the effect of satisfying the industrial quantification of production, saving production cost and time, and free and smooth use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

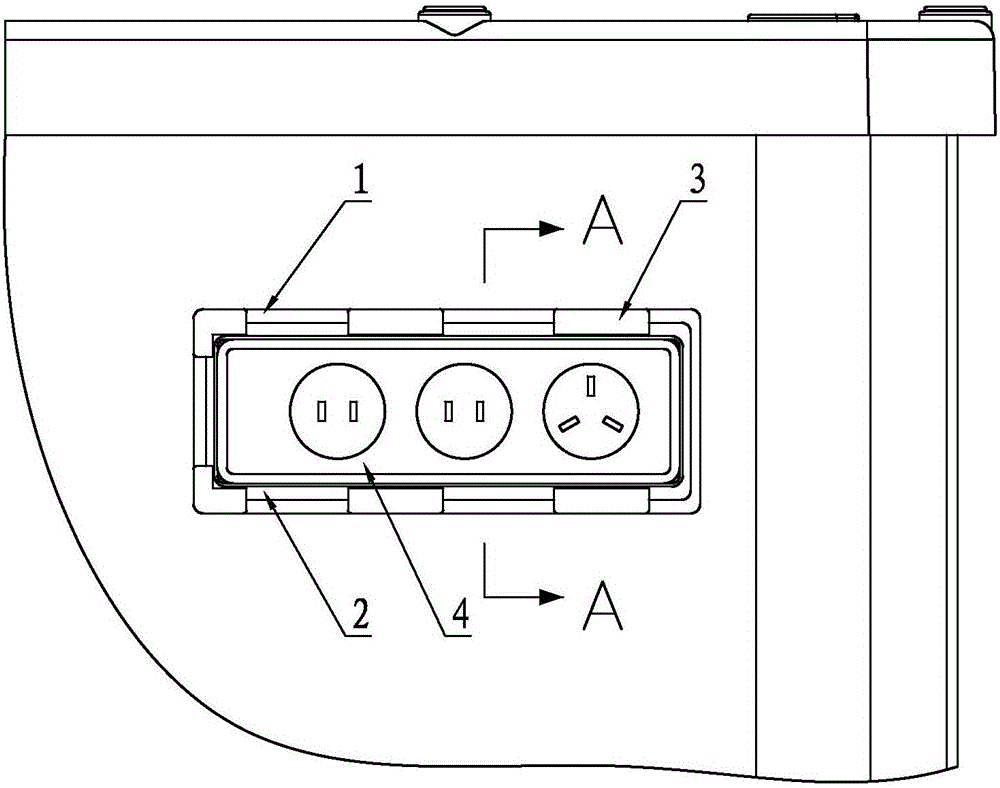

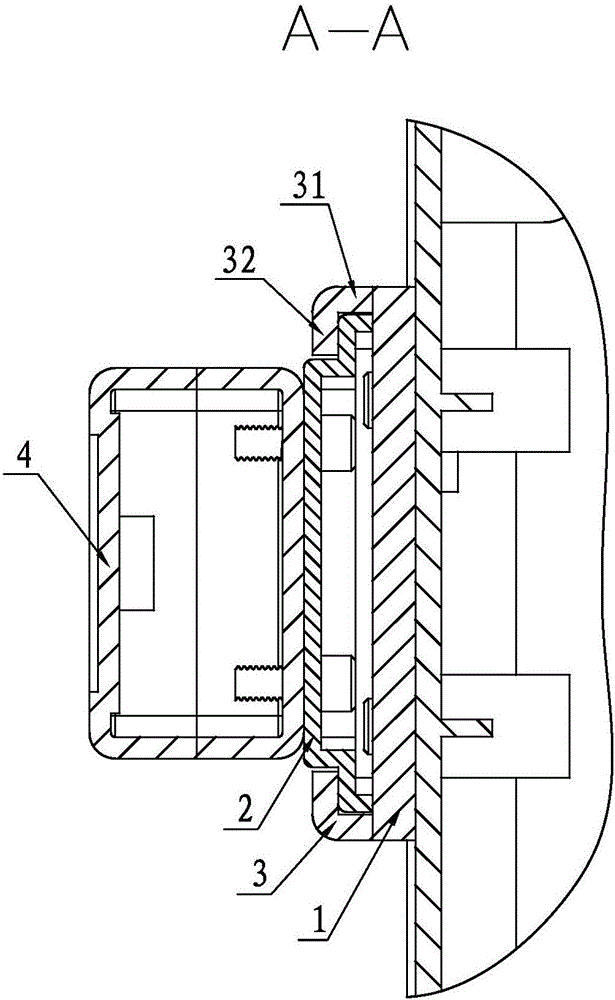

[0020] A medical trolley power socket fixing structure, such as Figure 1 ~ Figure 2 As shown, it includes the power supply bracket base 1 and the power supply connection bracket 2. There are four installation holes on the power supply bracket base 1, and four threaded holes are opened on the position corresponding to the installation holes on the back panel of the cart. The fastening screws pass through Fix the power supply bracket base 1 on the back panel of the cart through the installation holes and threaded holes, and set two edge limit blocks on the two long sides of the symmetrical plane of the contact surface between the power supply bracket base 1 and the back panel of the trolley 3. Two edge limit blocks 3 are arranged on one short side of the power supply support base 1. The edge limit blocks 3 are composed of a horizontal limit edge 31 and a vertical limit edge 32. The horizontal limit edge 31 and the vertical limit The fixed connection of the positioning side 32 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com