Multifunctional built-in tire pressure sensor

A tire pressure sensor and sensor technology, applied in tire measurement, tire parts, transportation and packaging, etc., can solve the problem of poor contact performance between the positive and negative plates of the battery and the battery, rusted metal cover plates and screws, and complicated battery operations. and other problems, to achieve the effect of simple, fast and convenient replacement method, stable electrical connection structure, and good electrical contact performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

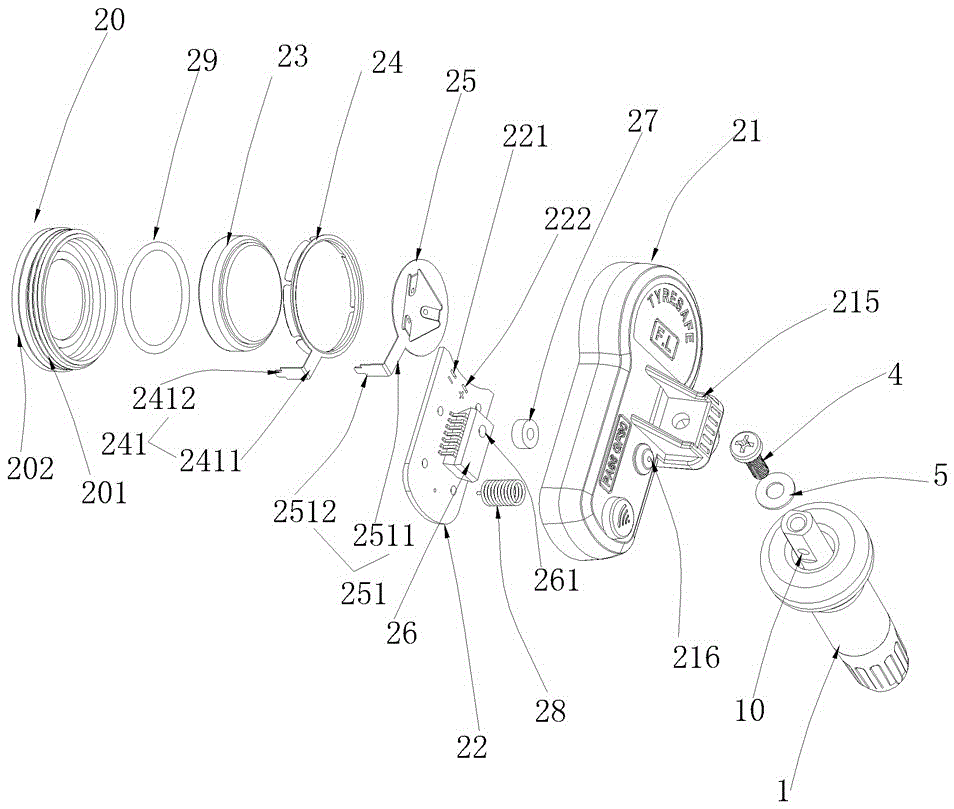

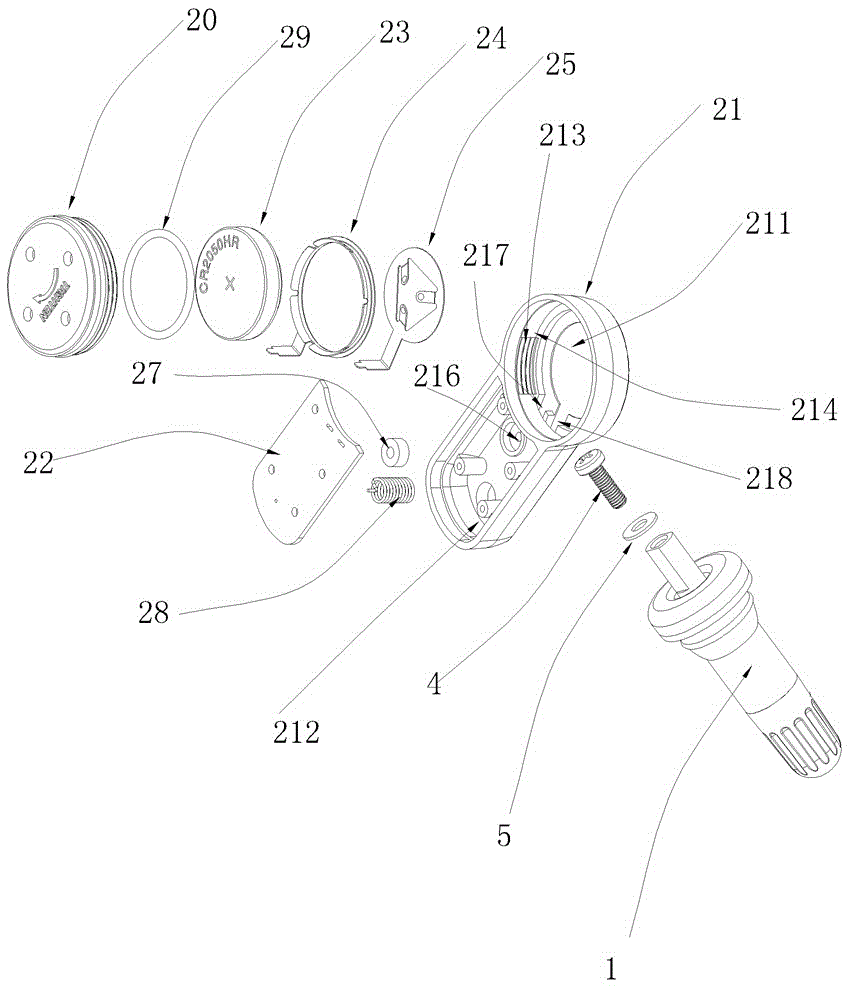

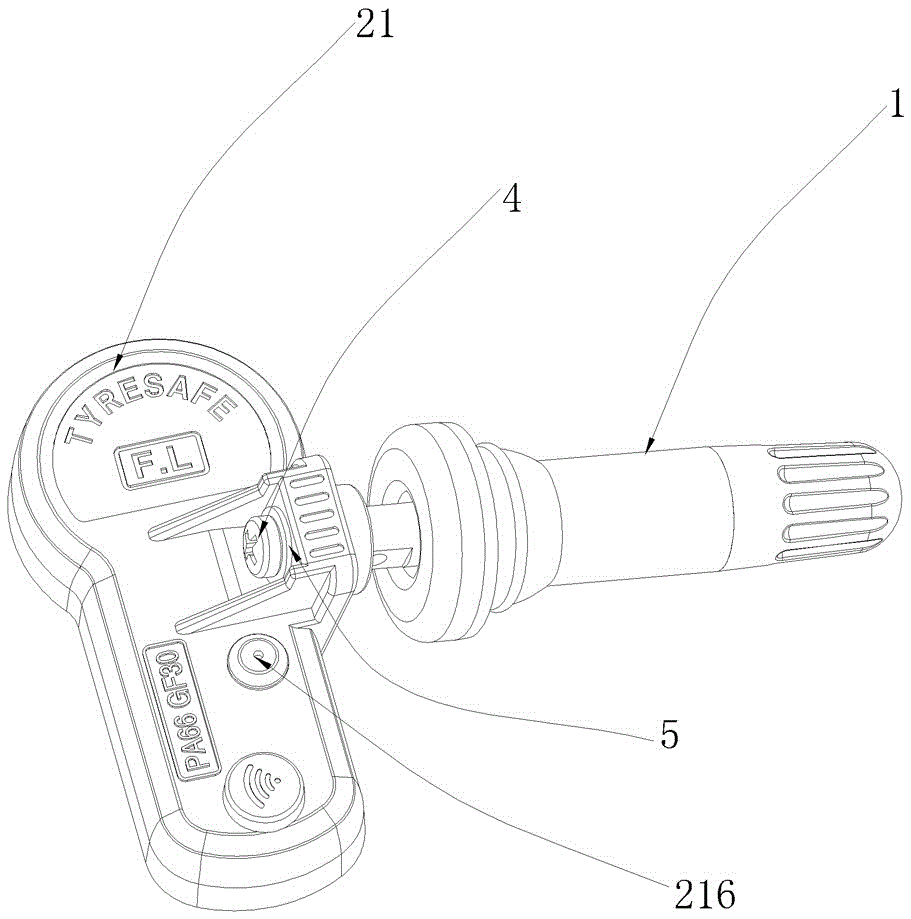

[0048] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

[0049] see Figure 1-3 , the multifunctional built-in tire pressure sensor provided by the present invention includes a valve 1 placed outside the tire and a sensor body 2 placed inside the tire. The valve 1 is detachably connected to the sensor body 2, and the valve 1 controls the Tire Air Refill;

[0050]The sensor main body 2 includes a battery cover 20, a sensor housing 21 and a PCB board 22. One end of the sensor housing 21 is embedded with a first accommodating groove 211. The battery cover 20 is detachably connected to the sensor housing 21, and the two are fixedly connected to the second housing. An accommodating groove 211 encloses a first sealed cavity for accommodating the button battery 23, the positive electrode sheet 24 of the battery and the negative electrode sheet 25 of the battery;

[0051] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com