Split type mechanical exploder and explosion valve cartridge case driving device

A driving device and detonator technology, which is applied in the direction of blasting barrels, weapon accessories, offensive equipment, etc., can solve problems such as inability to blast, achieve high reliability, and increase safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solution of the present disclosure, the present disclosure will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

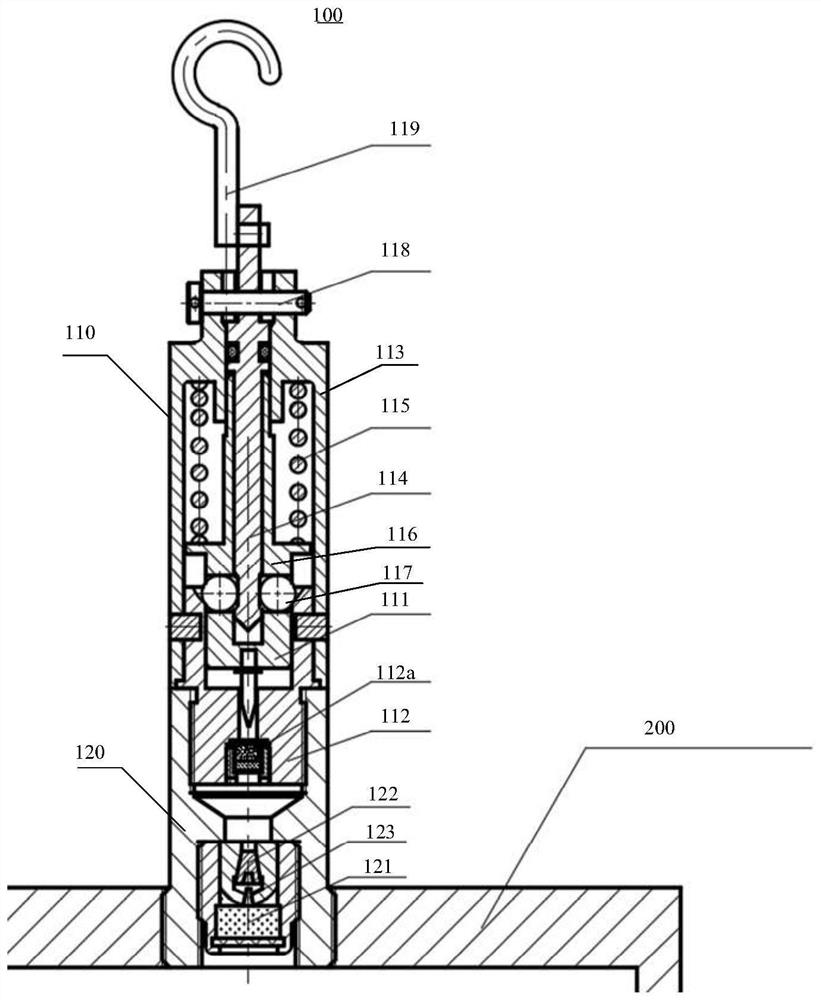

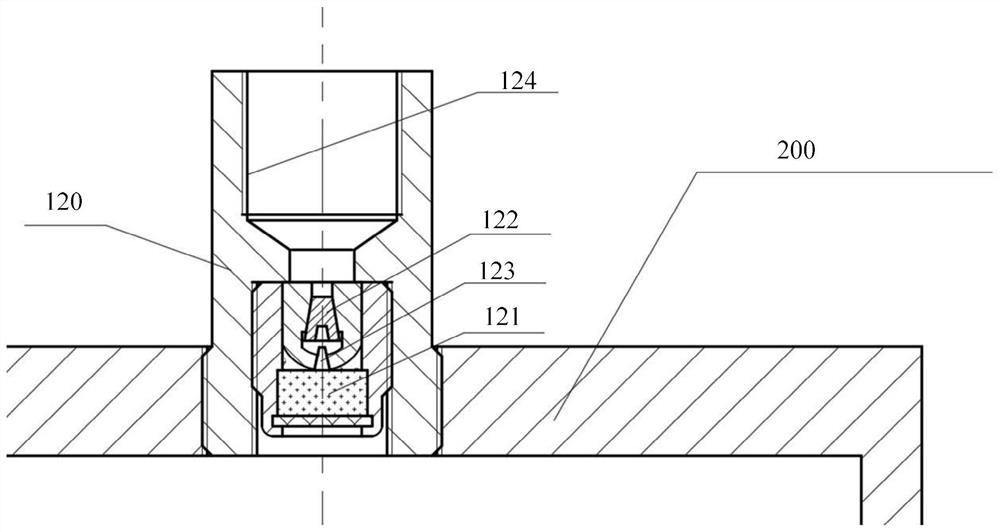

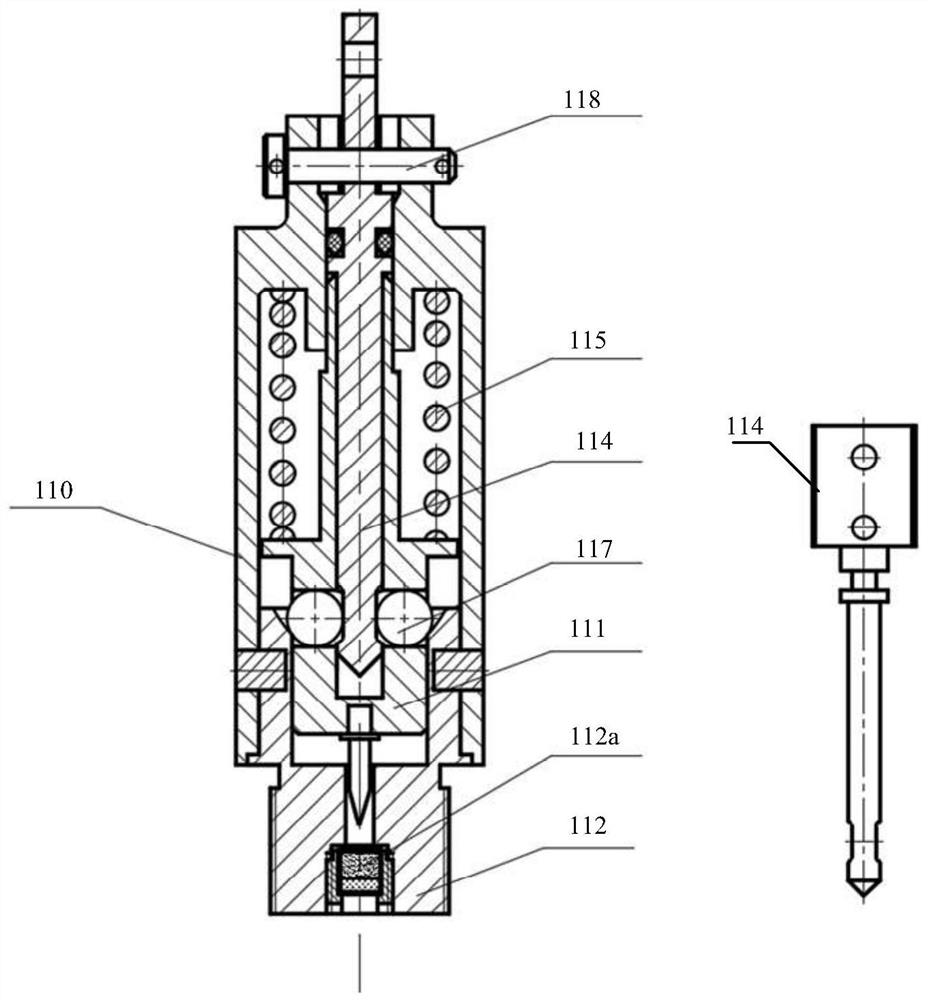

[0028] Such as Figure 1 to Figure 3 As shown, the embodiment of the present disclosure relates to a split type mechanical detonator 100 including an impact detonator 110 and a body 120 . The main body 120 is used to be installed on the cartridge driving device 200 to be blasted, and the main body 120 is provided with a secondary powder chamber 121 and a gas chamber 122, and the secondary powder chamber 121 is connected to the gas chamber 122 and the waiting The main powder chambers of the blasting cartridge driving device 200 are connected. The impact initiator 110 is detachably disposed on the body 120 .

[0029] The percussion initiator 110 includes a firing pin assembly 111 and a firing pin seat 112 . In the safe ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap