Non-stop drilling mesh type novel slag protection blasting cartridge sleeving outside of drill rod

A technology of blasting barrels and drill pipes, applied in the field of blasting, which can solve the problems of reduced reaction force and reduced blasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

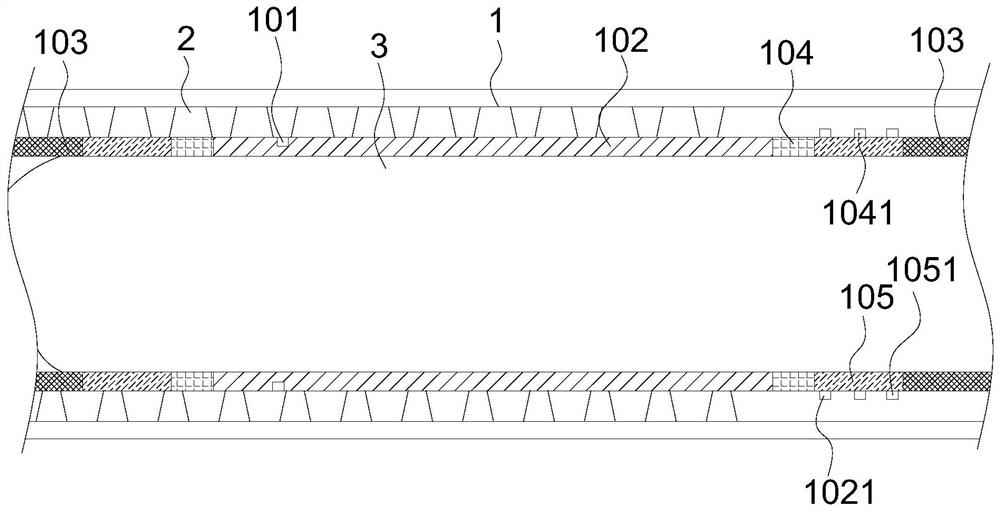

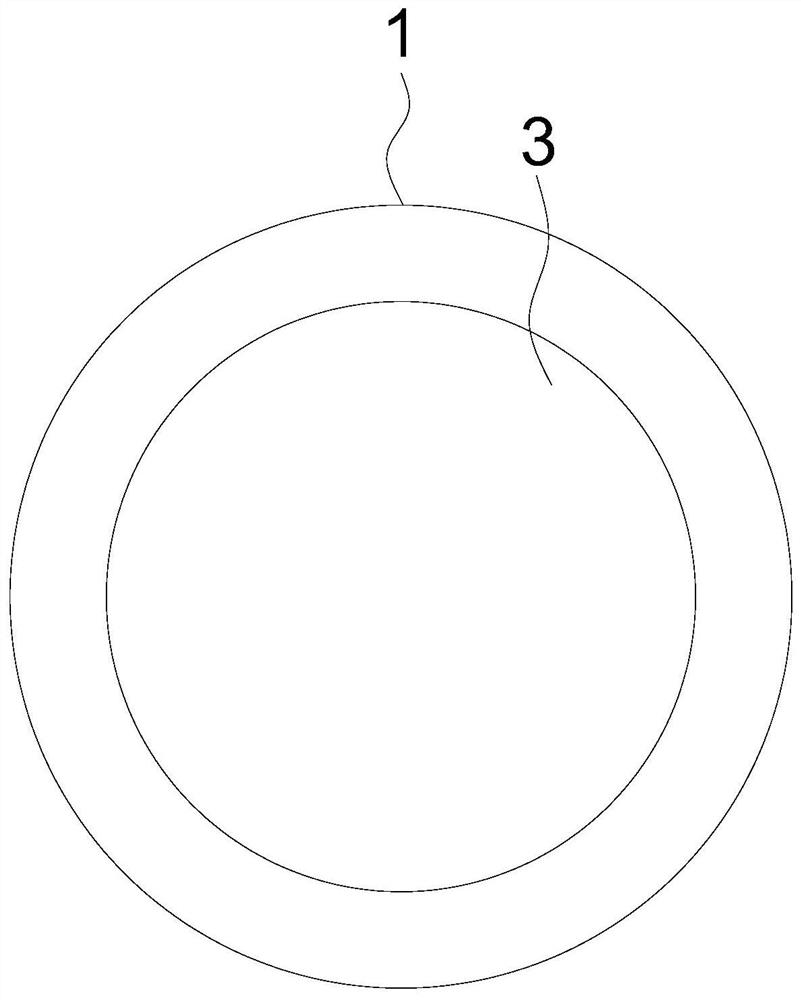

[0032] Please refer to figure 1 and figure 2 , figure 1 Shown is a schematic diagram of the cross-sectional structure of the blasting cylinder of the embodiment of the present invention; figure 2 Shown is a schematic diagram of the side view structure of the blasting cylinder body 1 of the embodiment of the present invention.

[0033]The embodiment of the present application provides a new type of slag-protecting blasting tube that is set outside the drill pipe and drills meshes continuously, including the blasting tube body 1, the ignition and detonation device 101 set in the blasting tube body 1 and the drill rod 3 sleeved in the blasting tube body 1 The blasting cylinder body 1 is provided with a blasting hole 2, and the explosive 102 connected with the ignition device 101 is filled between the blasting cylinder body 1 and the drill pipe 3. Both sides of the explosive 102 are provided with sealing assemblies along the length direction of the drill pipe 3. The blasting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com