Crushing process of intelligent and efficient crushing and shaping system in fine crushing workshop in sand and gravel processing plant

A processing plant, sand and gravel technology, applied in the direction of grain processing, etc., can solve the problems of scaffolding, sand and gravel production efficiency, and available mining volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

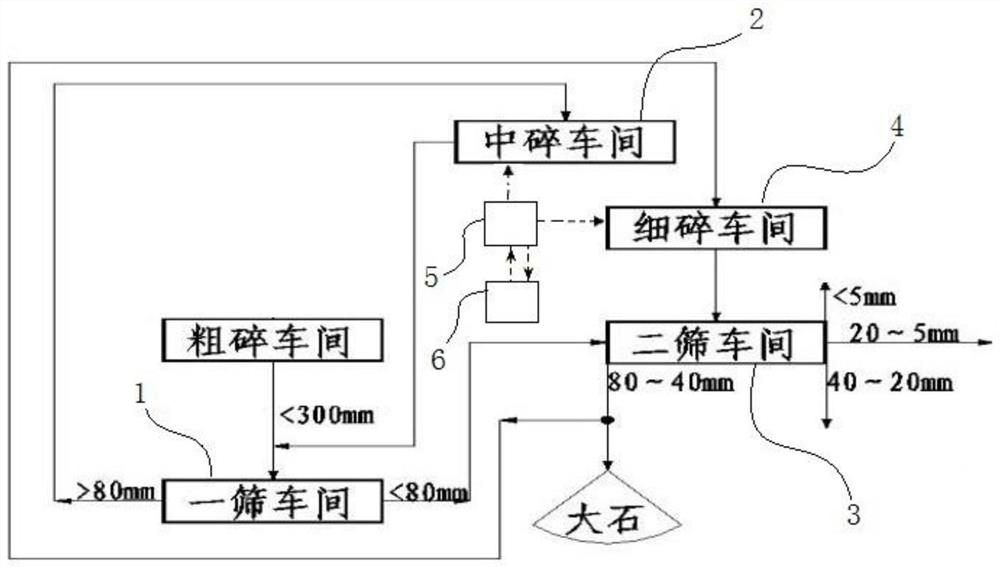

[0031] see figure 1 shown.

[0032] An intelligent and efficient crushing and shaping system for a fine crushing workshop in a sand and gravel processing plant of the present invention includes: a first sieving machine 1 for screening sand and gravel of 80mm and <80mm;

[0033] The first cone crusher 2 corresponding to the >80mm gravel outlet of the first screen machine 1 through the conveyor belt conveyor, and the conveyor belt conveyor transports the >80mm gravel in the first screen machine 1 to the first cone crusher The standard cavity in 2 is used for intermediate crushing, and the first cone crusher 2 constitutes the intermediate crushing workshop;

[0034] And the second sieve machine 3 corresponding to the <80mm gravel outlet of the first sieve machine 1 through the belt conveyor, which is in contact with the first sieve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com