A gas dust removal filter element fixing device and method thereof

A gas dust removal and fixing device technology, applied in separation methods, chemical instruments and methods, transportation and packaging, etc., can solve the problems of easy brittle fracture, non-vertical installation of ceramic filter elements, etc. Avoid the effect of dust trellis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

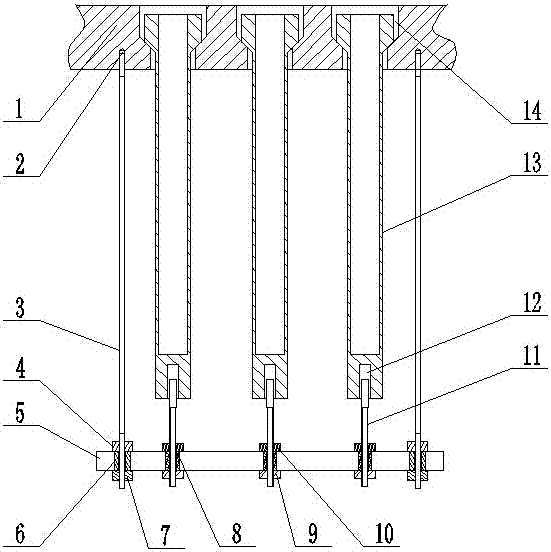

[0036] Such as figure 1 , figure 2 As shown, a gas dust removal filter element fixing device includes a partition 1, a filter element 13 arranged on the partition 1 and a filter element bracket arranged under the partition 1, and the tail of the filter element 13 is provided with a groove 12. The separator 1 is provided with several counterbores 14 whose shape matches the head of the filter element 13 , and the head of the filter element 13 is arranged in the counterbores 14 on the separator 1 .

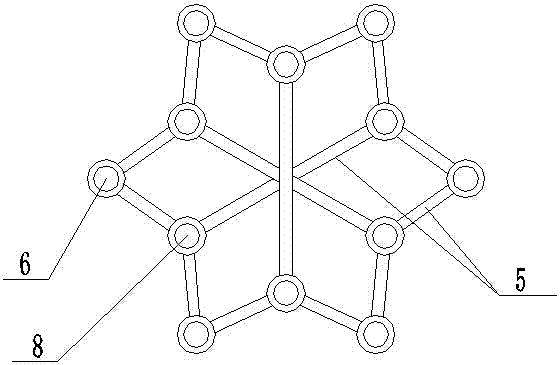

[0037] The filter element bracket includes a sleeve I6, a sleeve II8 and a strip 5, and the strip 5 connects the sleeve I6 and the sleeve II8 together.

[0038] A plurality of threaded holes 2 are provided on the lower surface of the partition 1, and the threaded holes 2 are internally threaded to connect with a pull rod 3, and the lower end of the pull rod 3 is penetrated and arranged in the setting sleeve I6.

[0039] The distance between the separator 1 and the filter element b...

Embodiment 2

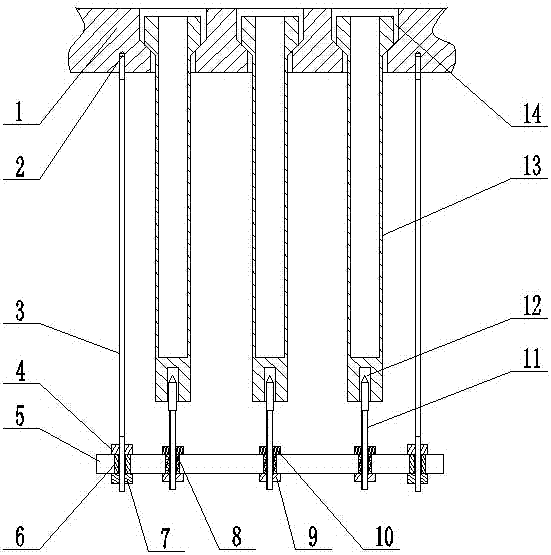

[0051] Such as image 3 , Figure 4 As shown, a gas dust removal filter element fixing device includes a separator 1, a filter element arranged on the separator 1 and a filter element bracket arranged below the separator 1, and a groove 12 is provided at the tail of the filter element. Several counterbores 14 whose shapes match the head of the filter element are arranged on the partition 1 , and the filter head is arranged in the counterbore 14 on the partition 1 .

[0052] The filter element bracket includes a sleeve I6, a sleeve II8 and a strip 5, and the strip 5 connects the sleeve I6 and the sleeve II8 together.

[0053] A plurality of threaded holes 2 are provided on the lower surface of the partition 1, and the threaded holes 2 are internally threaded to connect with a pull rod 3, and the lower end of the pull rod 3 is penetrated and arranged in the setting sleeve I6.

[0054] The distance between the separator 1 and the filter element bracket is adjusted by the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com