High-precision automatic feeding instrument

A high-precision, feeder technology, applied to chemical instruments and methods, dissolution, mixers, etc., can solve the problems of low precision, high precision, low efficiency, etc., achieve high feeding efficiency and prevent materials from sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

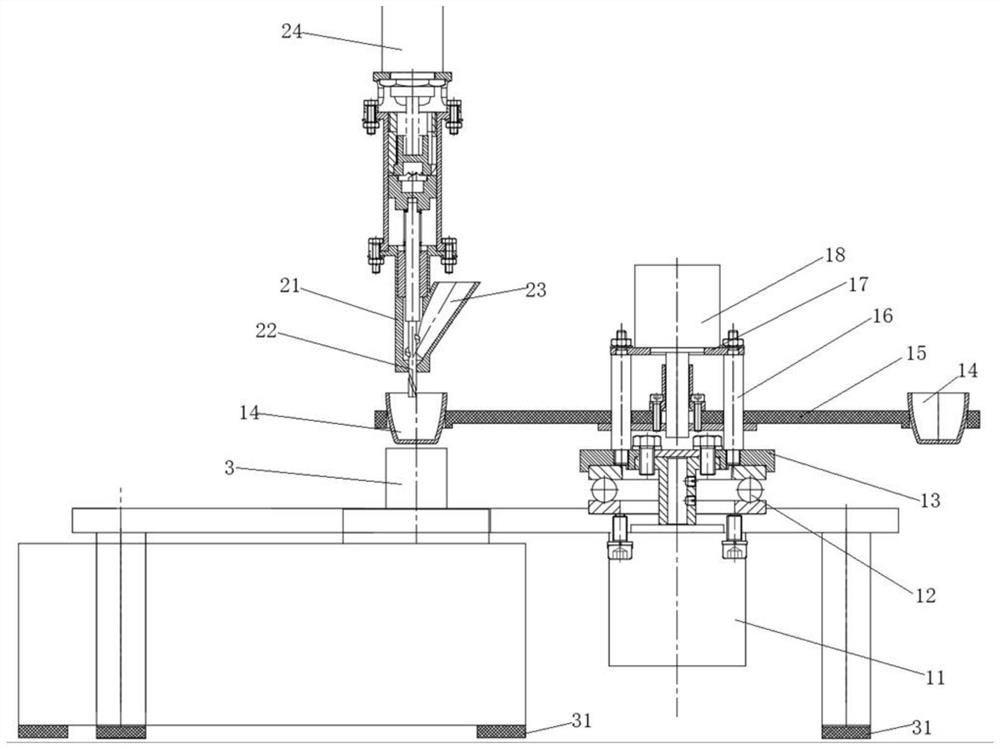

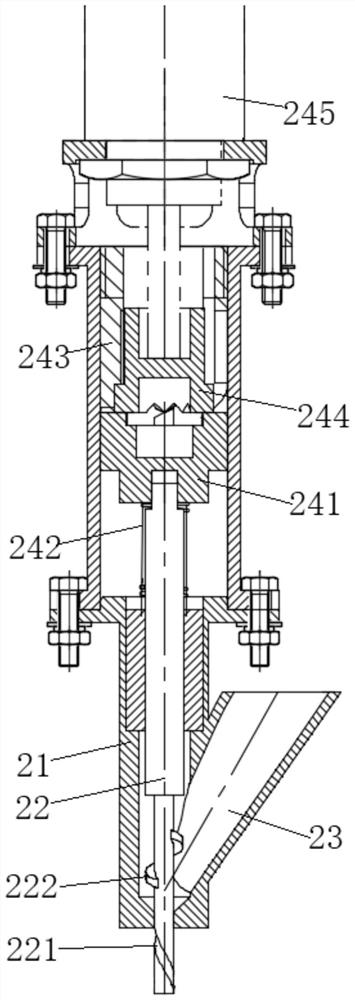

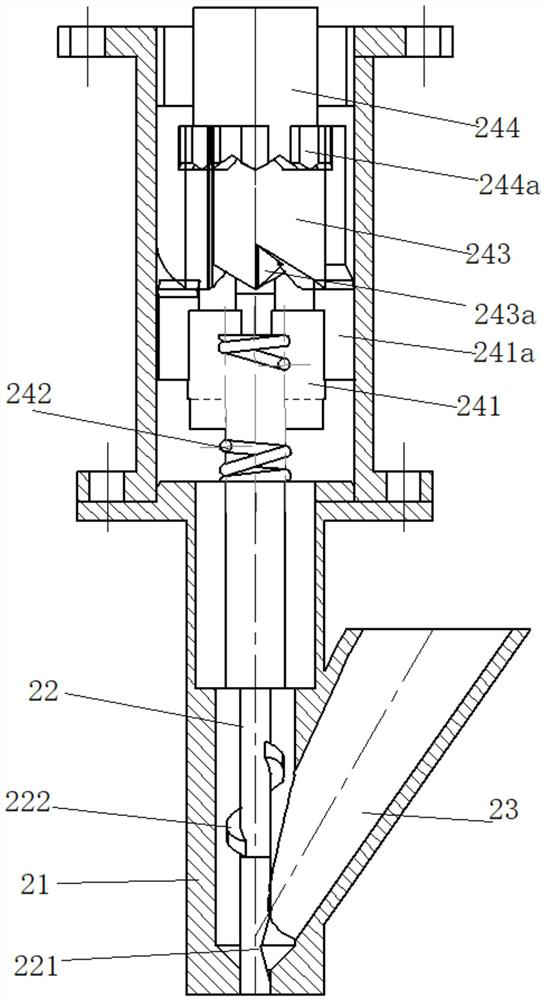

[0031] Such as Figure 1 to Figure 9 As shown, a high-precision automatic feeding instrument includes a material storage system, a feeding system and a weighing platform 3; the material storage system is used to put crucibles 14 on the weighing platform 3 one by one and after the weighing reaches a preset value Carried away, including the tray 15, the rotating motor 11 that can drive the tray 15 to rotate, the crucible 14 distributed around the center of rotation, and the lifting motor 18 that can drive the tray 15 up and down. Platform 3, the crucible 14 is lowered onto the weighing platform 3 with the tray 15, and then the tray 15 continues to descend to be able to separate from the crucible 14; the feeding system is used to sequentially feed the crucible 14 on the weighing platform 3 until the weighing reaches the preset value value, including a fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com