Single-Pass printing device, control method and printing equipment

A technology for printing devices and controllers, applied in printing devices, printing, typewriters, etc., which can solve problems such as excessive ink output and unclear ink dots in printed pictures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

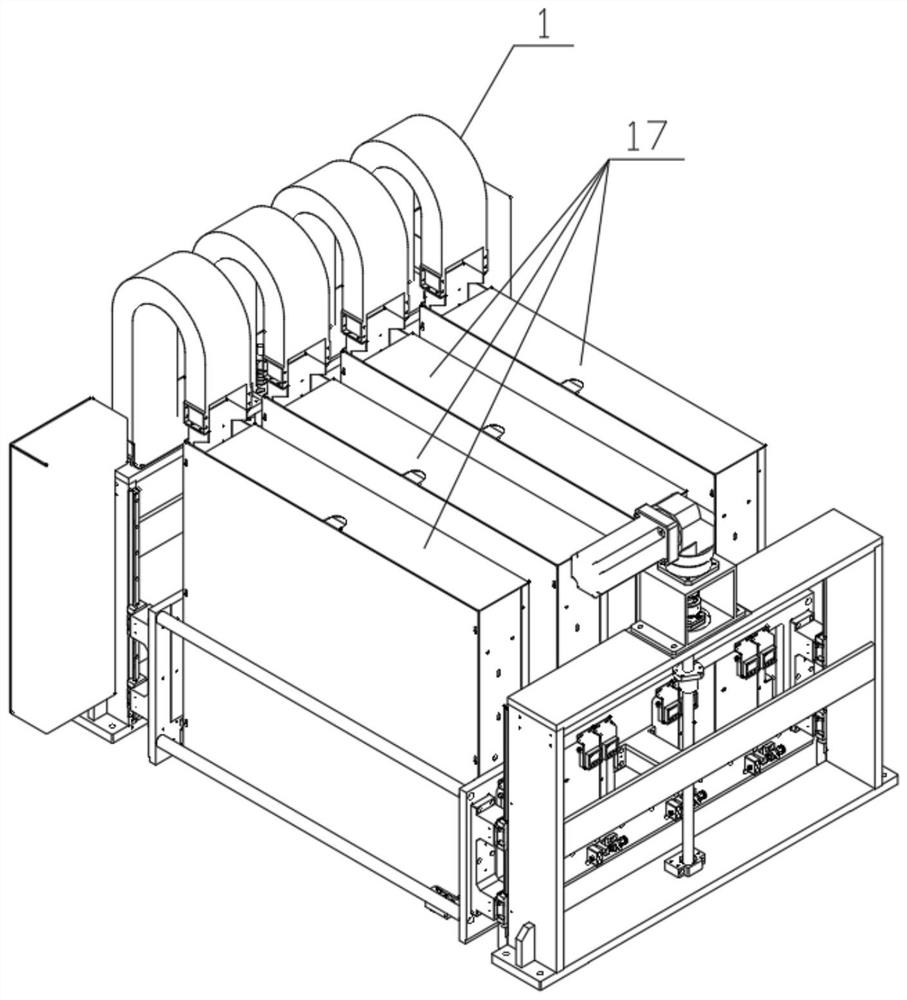

[0053] Embodiment 1 of the present invention discloses a Single-Pass printing device 1. Single-Pass printing means: the nozzle head is fixed without moving, and the printing medium 2 can obtain the pattern to be printed once it passes under the nozzle head, and the printing medium 2 It is a continuous motion, no pause printing method.

[0054] Specifically, the printing device 1 includes: a first printing module 11, including at least one nozzle, for inkjet printing a first type of ink and a second type of ink different from the first type of ink;

[0055] The second printing module 12 includes at least one nozzle for inkjet printing of the first ink and the second ink, wherein the first printing module 11 and the second printing module 12 are separated by a preset distance and on the printing medium 2 Parallel arrangement in the transmission direction;

[0056] a controller, the controller divides the ink volume of the first ink in the print data corresponding to the target ...

Embodiment 2

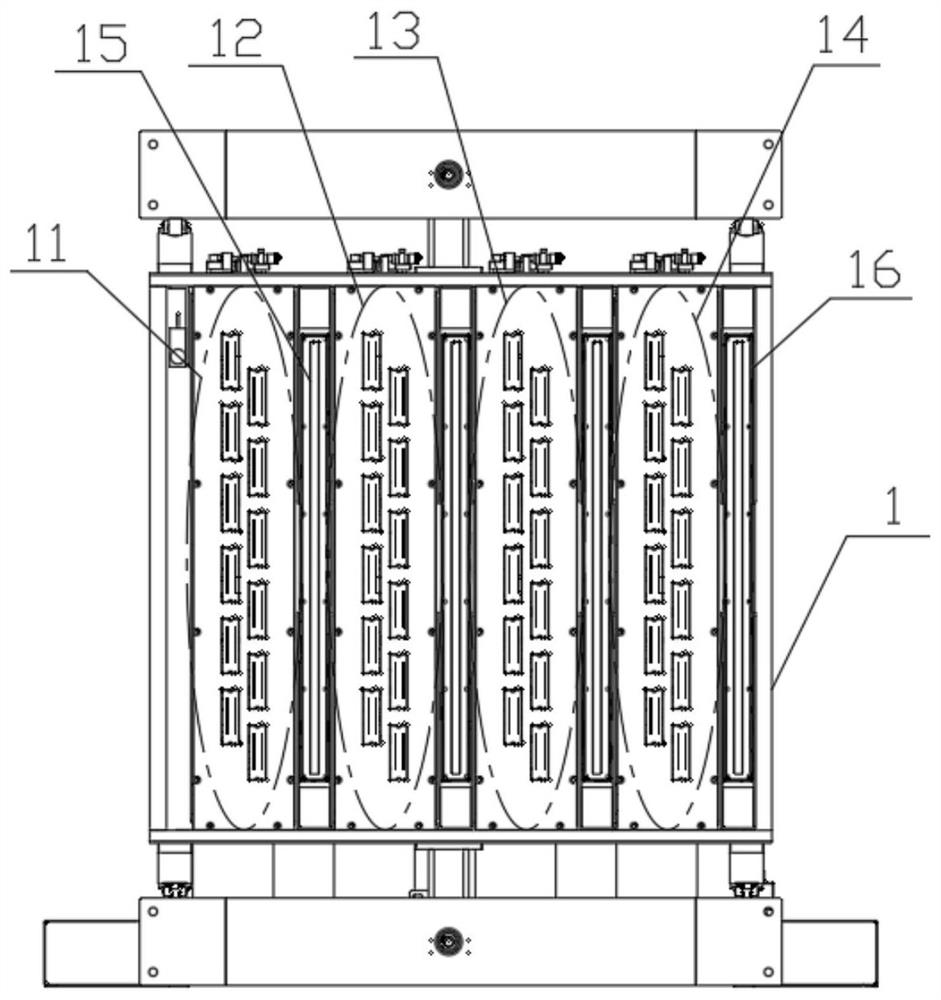

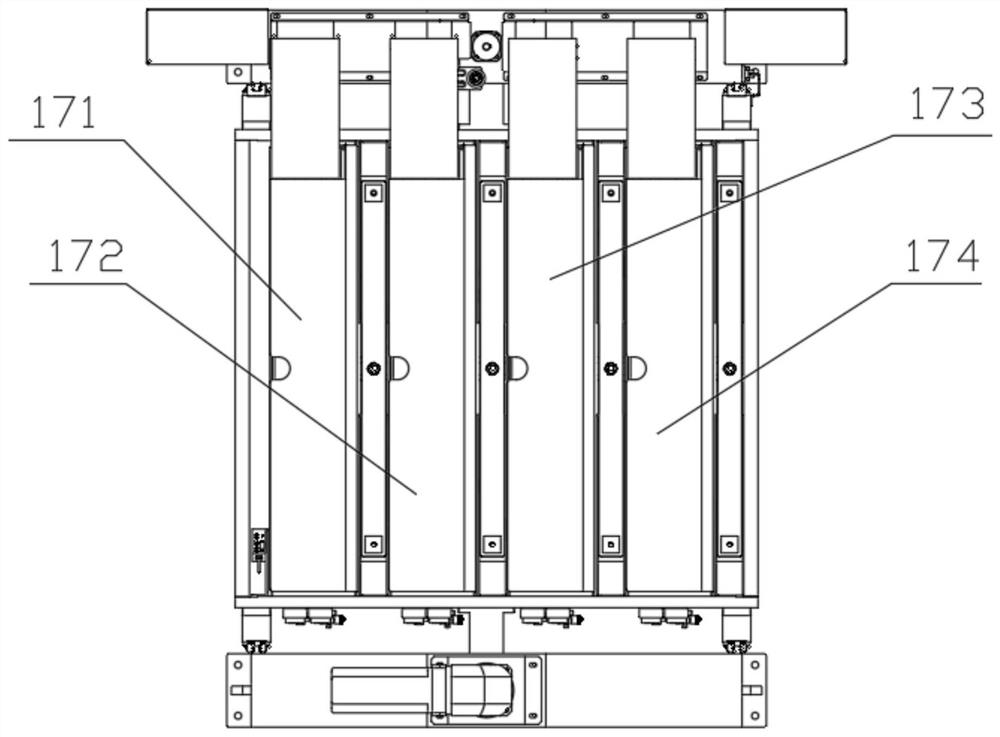

[0062] See Figure 1 to Figure 6 , the Single-Pass printing device 1 in Embodiment 2 of the present invention is improved on the basis of Embodiment 1.

[0063] Specifically, the printing device 11 includes a first printing module 11, a second printing module 12, a third printing module 13, a fourth printing module 14, a pre-curing mechanism 15 and a final curing mechanism 16, wherein the first printing module 11. The pre-curing mechanism 15, the third printing module 13, the pre-curing mechanism 15, the fourth printing module 14, the pre-curing mechanism 15, the second printing module 12 and the final curing mechanism 16 are parallel in sequence along the transmission direction of the printing medium 2 arranged in a row, and there is a preset distance between adjacent printing modules, the preset distance is a distance capable of accommodating the pre-curing mechanism 15, and the pre-curing mechanism 15 is arranged at the adjacent interval of the printing modules, which can m...

Embodiment 3

[0088] The Single-Pass printing device 1 in the third embodiment of the present invention is improved on the basis of the first embodiment.

[0089] Specifically, the printing device 1 includes a plurality of printing modules, a controller, a pre-curing mechanism 15 and a final curing mechanism 16 . Wherein each printing module includes a plurality of printing units, because the printing ink base color is four, so here preferably set four printing units in each printing module, here is not the quantity of printing units or printing modules limit, each printing unit prints one ink. The controller is electrically connected with the printing module, the pre-curing mechanism 15 and the final curing mechanism 16 . The controller splits the ink volume of the same ink in the print data corresponding to the target print image into multiple printing modules, and the controller controls the printing units printing the same ink to print again in the same area. By setting up multiple se...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap