Ink feed regulator for ink feeder

A volume adjustment and ink feeding technology, which is applied to the general parts of printing machinery, printing, printing machines, etc., can solve the problems of increased cost, increased number of parts, inconvenience, etc., and achieve the effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

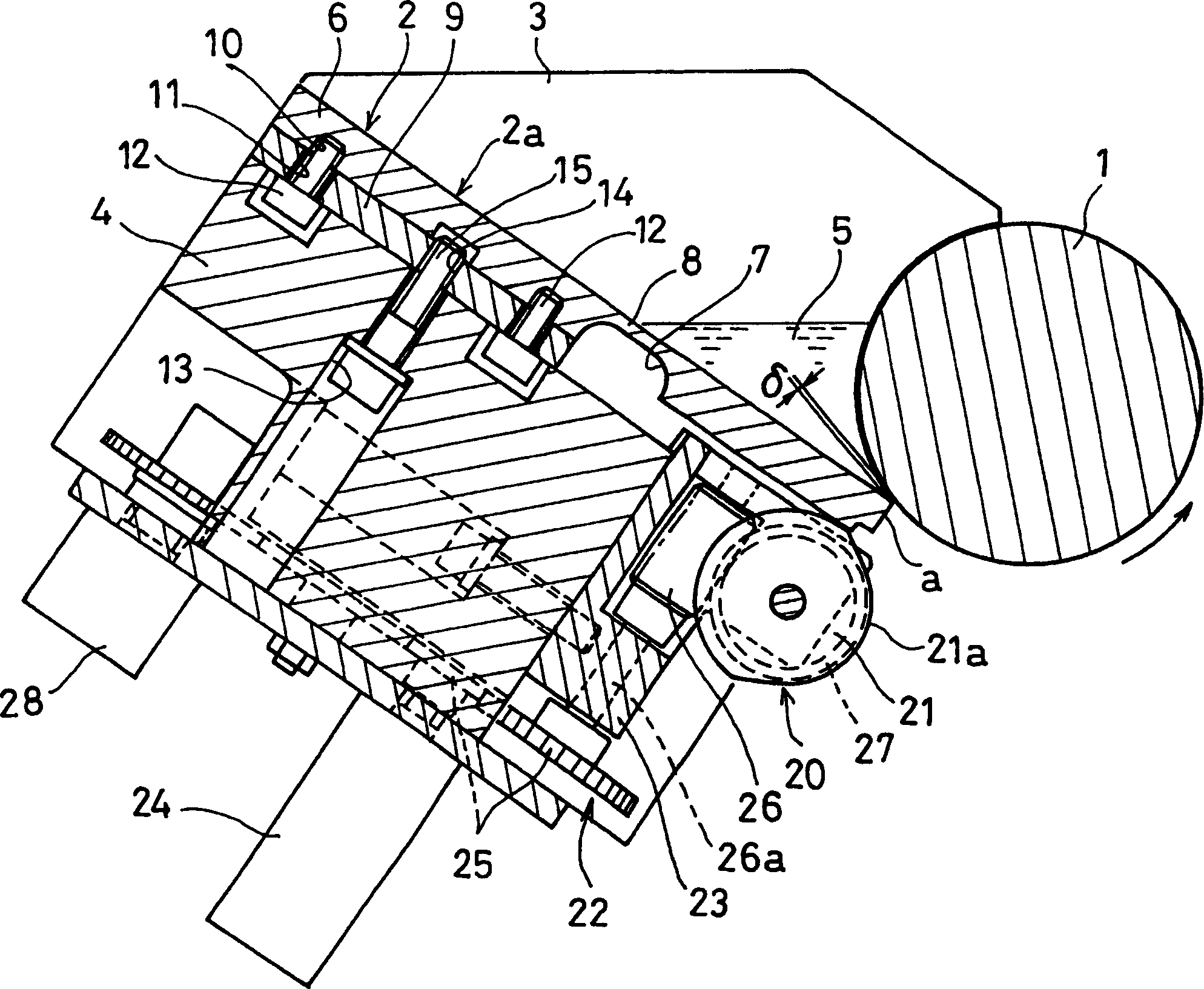

[0023] Below, according to Figure 1 ~ Figure 3 Embodiments of the present invention will be described. Such as figure 1 As shown, the lower part of the outer periphery of the ink fountain roller 1 rotating in the direction of the arrow in the figure is adjacent to the front end of the ink fountain scraper 2, and a gap δ is provided between the front end and the outer peripheral surface of the ink fountain roller 1.

[0024] The ink fountain scraper 2 is arranged in an inclined shape with the front end sloping downward, and a pair of baffles 3 are provided on both sides of the ink fountain scraper 2 . A pair of baffles 3 are attached to the support table 4 provided below, and the ink fountain 5 is installed on the ink fountain blade 2 by attaching the baffles 3 .

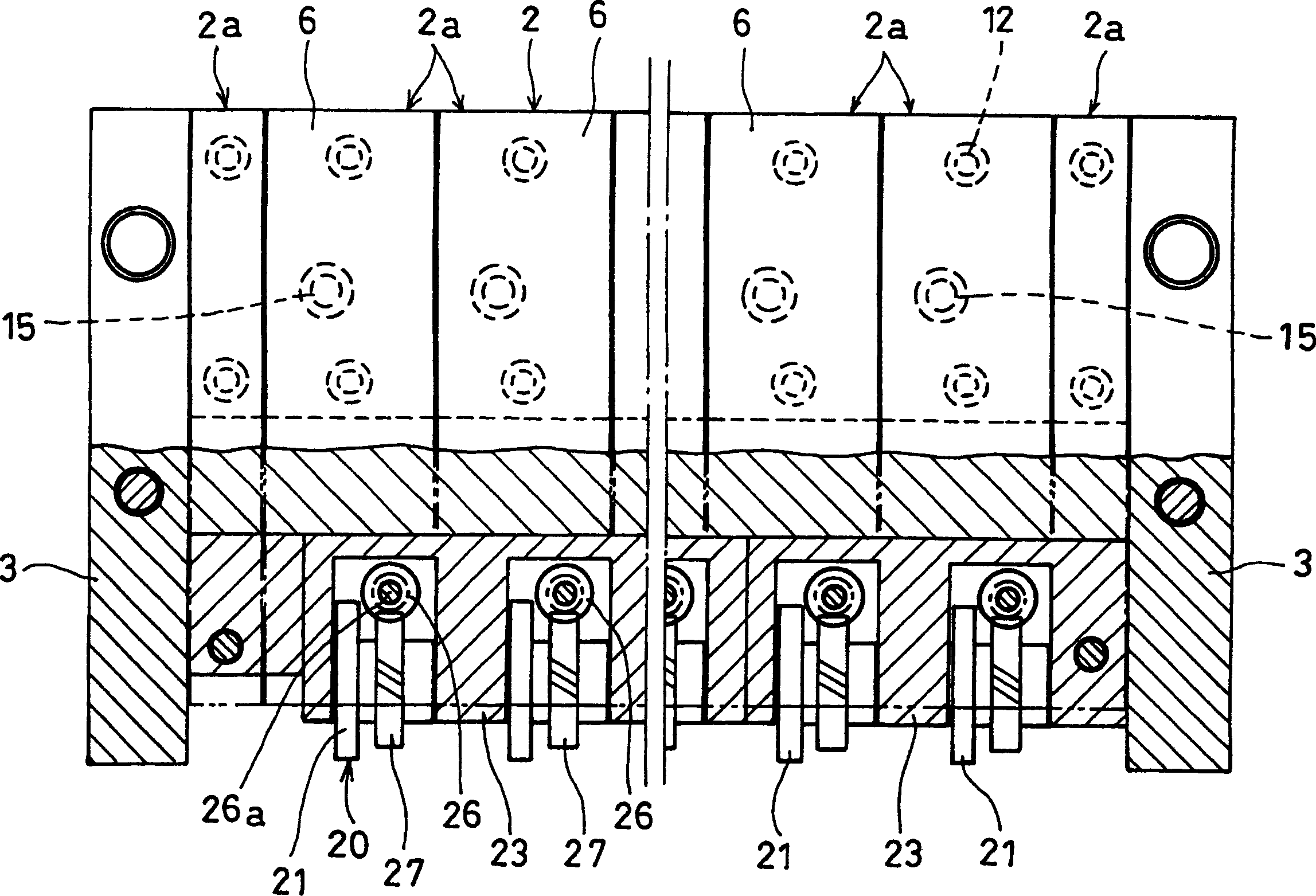

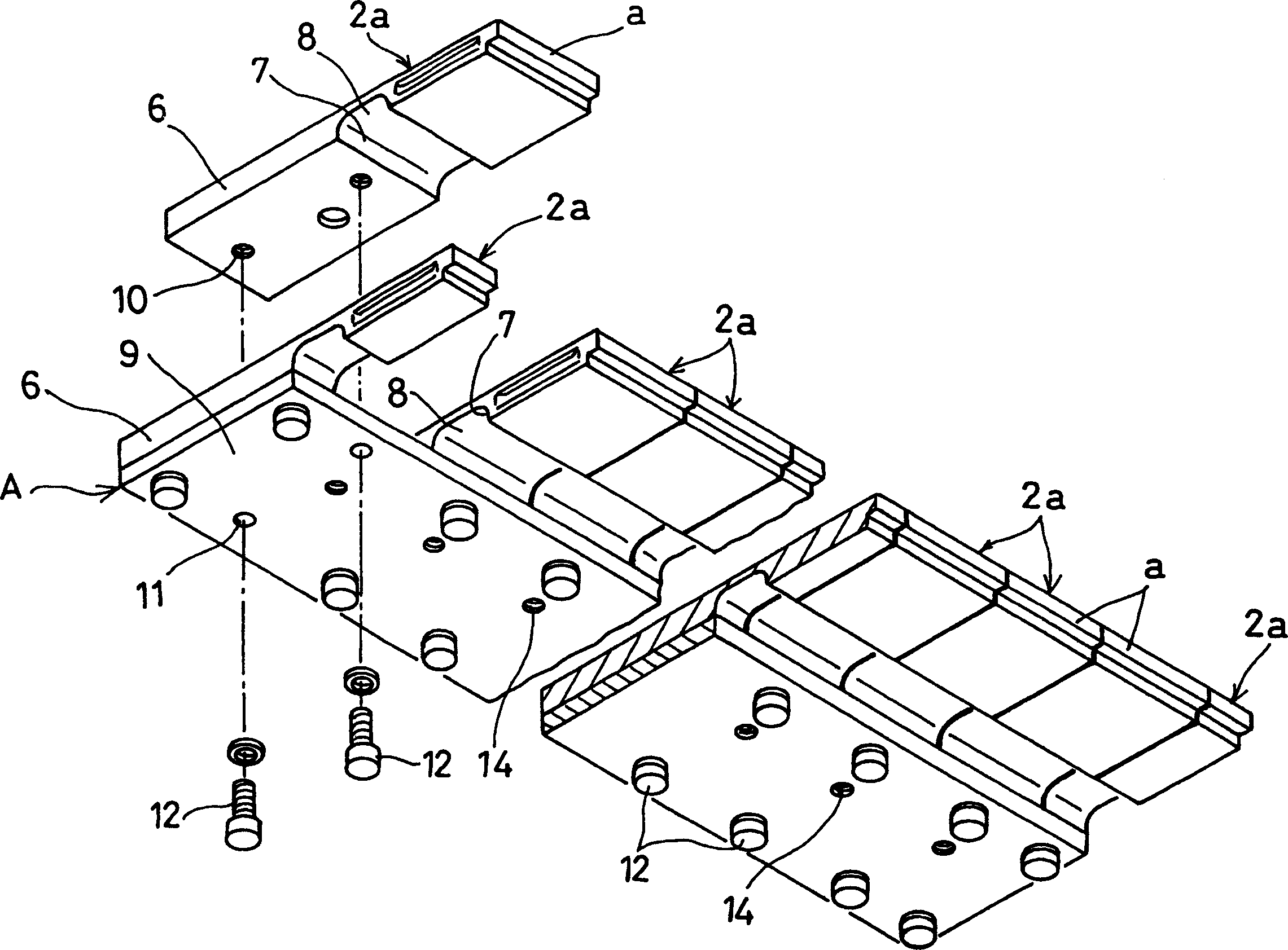

[0025] Such as figure 2 and image 3 As shown, the ink fountain scraper 2 is composed of a plurality of key bar scrapers 2a. The rear end of each key bar scraper 2a is a mounting portion 6, a groove 7 penetrat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap