Double-channel graded wide-range-adjustable air inlet channel, engine and air inlet adjusting method

An air inlet, dual-flow technology, applied in engine components, combustion engines, machines/engines, etc., can solve the problem of difficulty in taking into account the performance at high Mach and the starting ability at low Mach number at the same time, and achieve high Mach number and high total. The effect of pressure recovery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and exemplary embodiments.

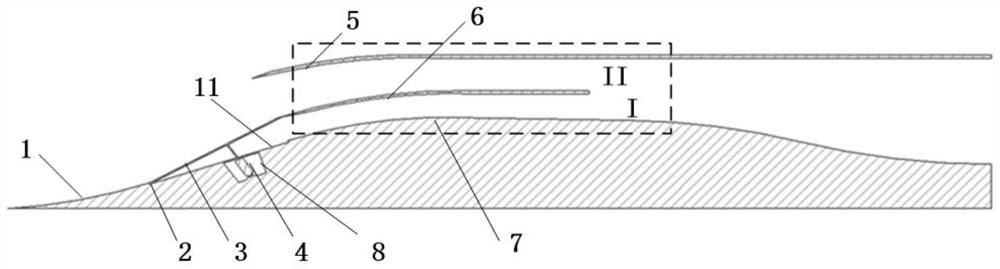

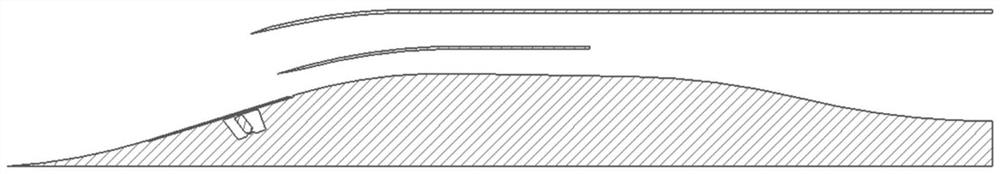

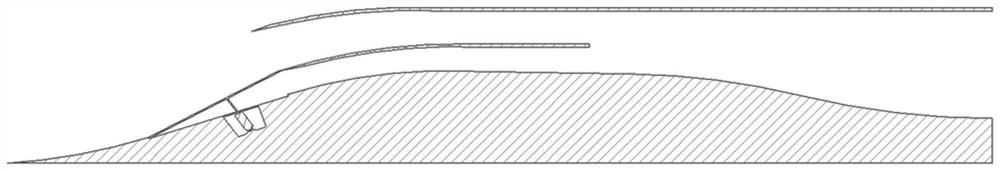

[0038] refer to figure 1 , a dual-channel graded adjustable wide-range air intake, comprising an intake top compression surface 1, an intake compression surface 11, an intake throat curved surface 7, a lip cover 5, a splitter plate 6, an adjustment plate 3, Actuating cylinder 4 and installation chamber 8; the air inlet top compression surface 1, the air inlet compression surface 11, and the air inlet throat curved surface 7 are sequentially located on the inner side of the air inlet along the airflow direction, and the air inlet top compression Surface 1 is an isentropic curved compression surface generated by a wedge shape or a characteristic line, and the top compression surface 1 of the air inlet is a fixed compression surface at the front end of the air inlet, which has no change in the span direction and is a binary structure; the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com