Non-contact high-precision powder metering system

A metering system, non-contact technology, applied in the field of non-contact high-precision powder metering system, can solve the problems of unsatisfactory industrial production, high labor intensity of workers, low production efficiency, etc., and achieve the goal of improving quality and production Efficiency, fast delivery, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

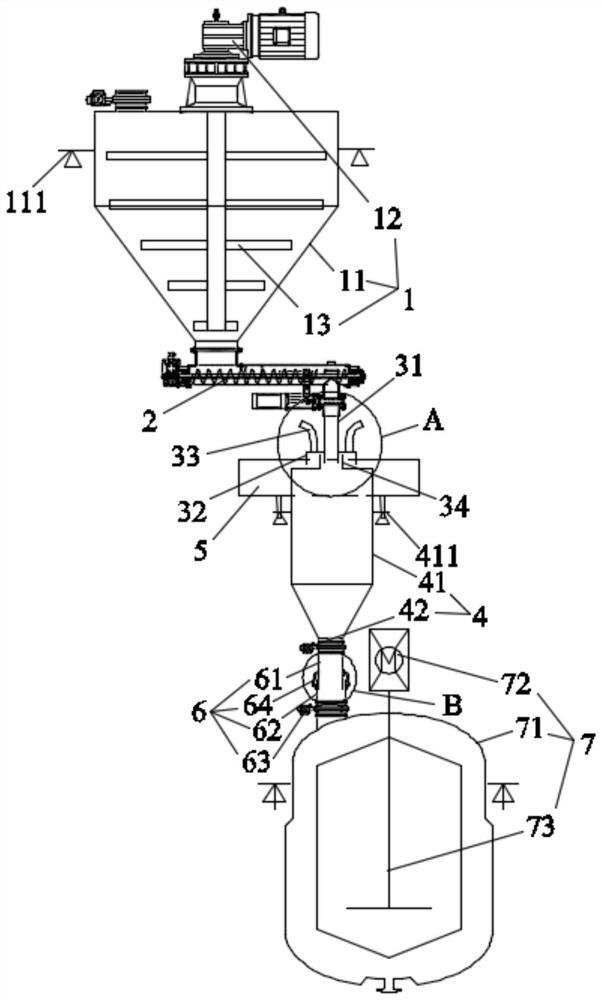

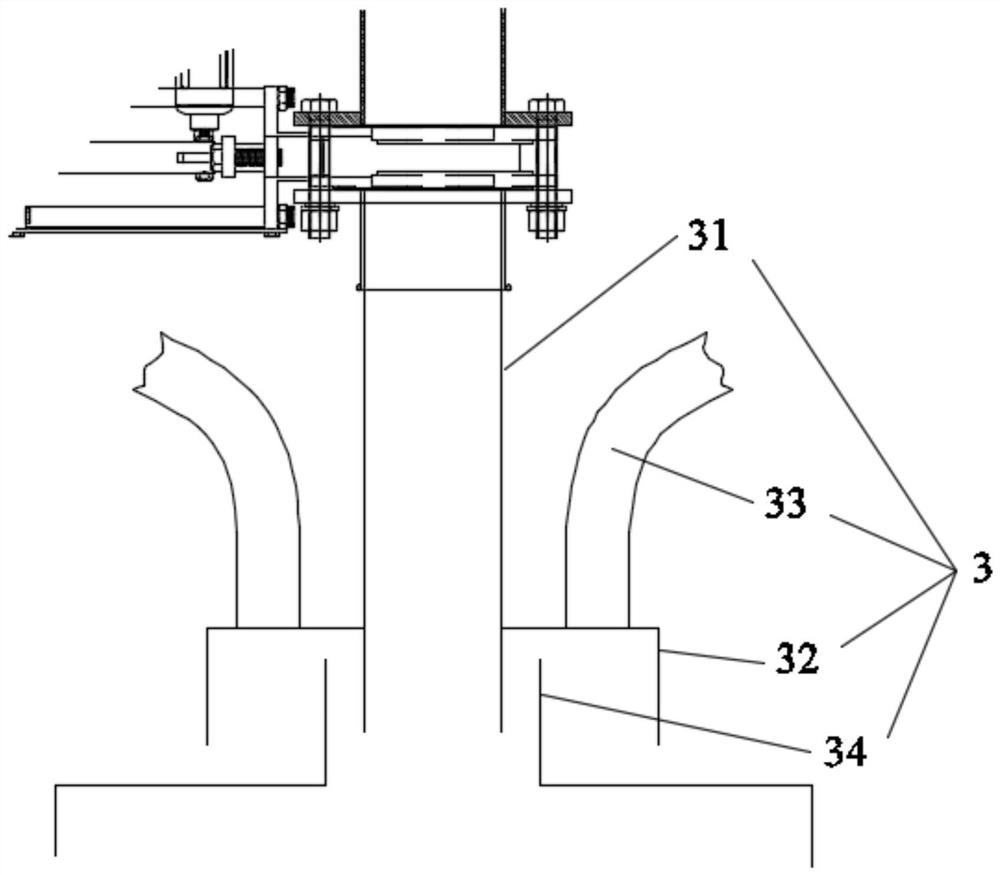

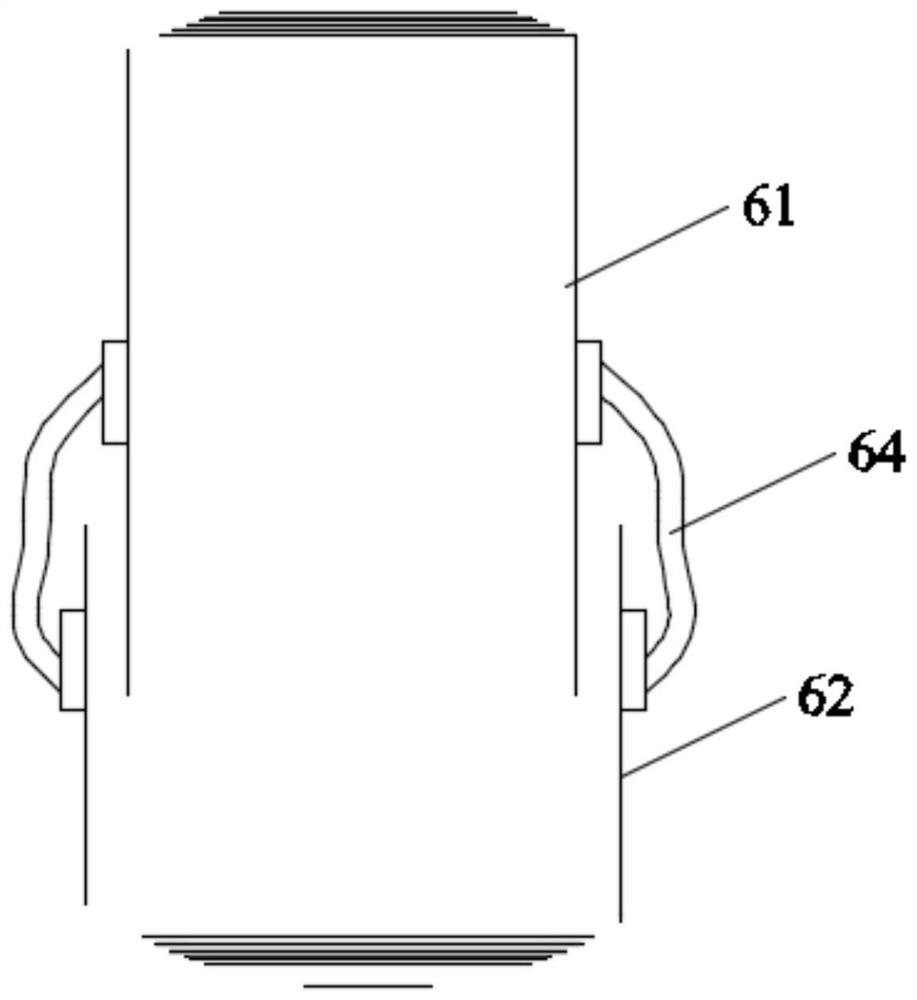

[0028] Such as Figure 1-3As shown, a non-contact high-precision powder metering system includes a first storage device 1, a feeding device 2, a first feeding device 3, a second storage device 4 and a weighing device 5, the first storage device The device 1, the feeding device 2, the first feeding device 3, and the second storage device 4 are sequentially connected from top to bottom. The second storage device 4 includes a first storage tank 41 and a first valve 42. The first valve 42 Set at the outlet of the first storage tank 41, the side of the first storage tank 41 is provided with a first hanging lug 411, the first hanging lug 411 is connected with the output end of the weighing device 5, the first feeding device 3 includes the first A pipe body 31, a dust suction cover 32, a dust removal air pipe 33 and a second pipe body 34, the first pipe body 31 is arranged on the feeding device 2, the first pipe body 31 communicates with the discharge port of the feeding device 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com