An optimization method for fine adjustment of ballastless track with dual-track combined constraints

A ballastless track and constraint equation technology, applied in the field of railway engineering, can solve the problems that the optimization results do not meet the requirements of smoothness, restrict the fine adjustment operation effect of the reference rail, and have limited operation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

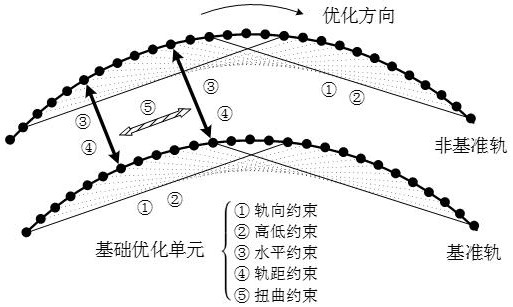

[0051] The following is attached Figure 1~4 The present invention is described in further detail.

[0052] A ballastless track fine-tuning optimization method with dual-track combination constraints, the specific implementation of the method is as follows:

[0053] The rail part of the ballastless track includes: the left rail and the right rail. The fine adjustment operation stipulates that the left rail is the reference rail and the right rail is the non-reference rail. Therefore, the reference rail and the non-reference rail can be collectively called the left and right rails.

[0054] Step 1: Measure the three-dimensional coordinates of the reference rail and non-reference rail of the ballastless track. The location of the measurement coordinates is called the measuring point. Compare the coordinates of the design line corresponding to the mileage of the measuring point with the measurement coordinates, and compare the three-dimensional coordinates of the track design pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com