Hand-operated stamp having a tilting element

A technology of seals and components, applied in the field of two locking elements, can solve problems such as complex structures and large manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

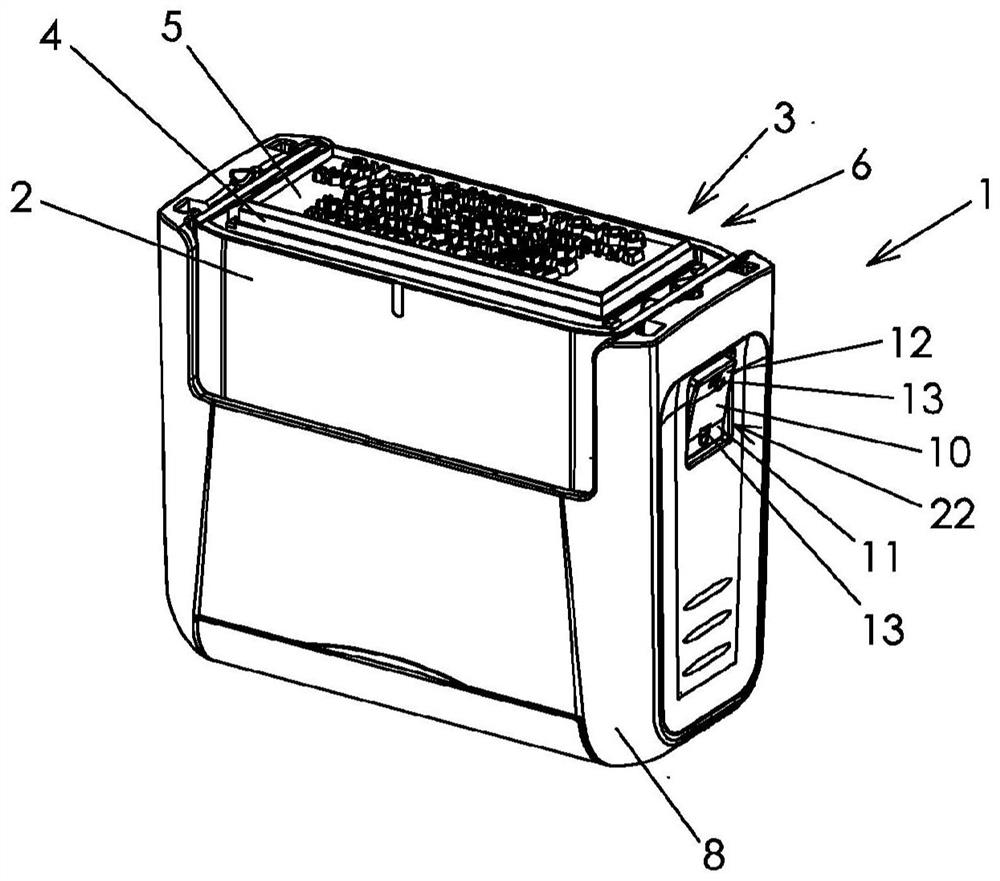

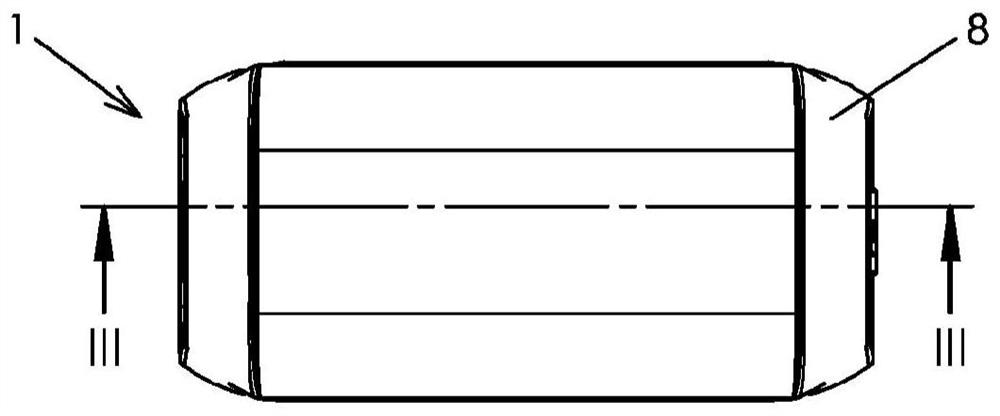

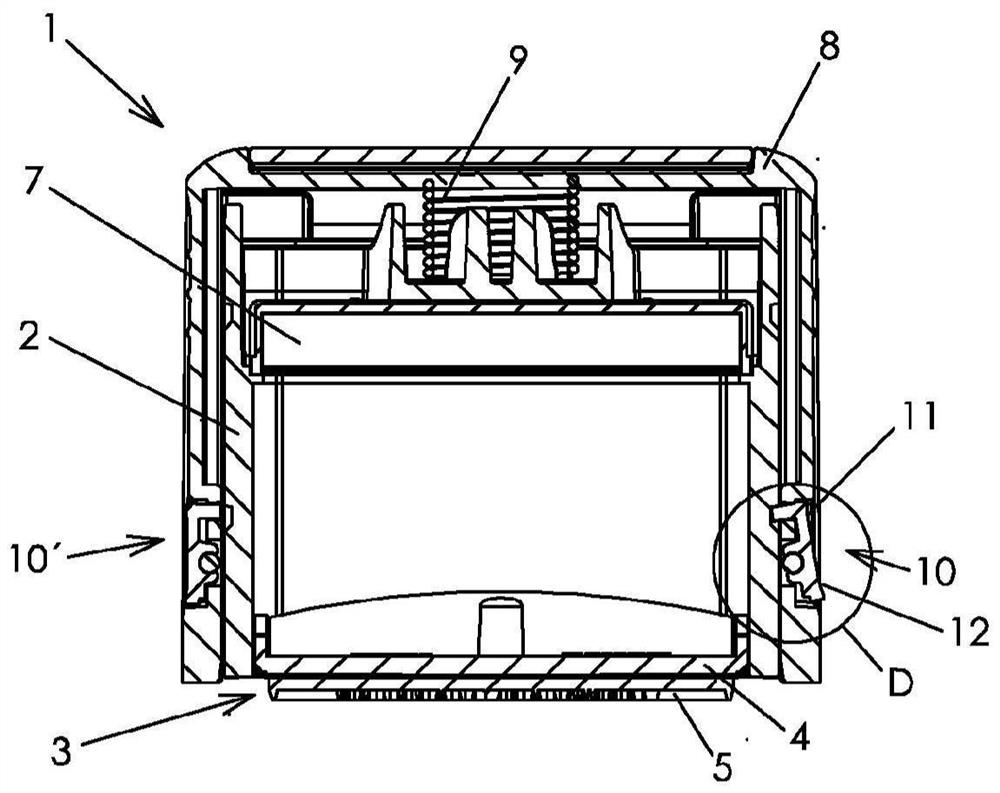

[0036] figure 1 A manual stamp 1 , which is designed as a self-inking stamp with upper impact inking, is shown partially from below, ie towards the underside or stamping side. image 3 along figure 2 The sectional view shown in section line III-III shows the same manual stamp 1 . The manual stamp 1 has a housing 2 , in which a stamp unit 3 is mounted, which has a stamp plate 5 mounted on a plate carrier 4 . As an alternative or supplement to the stamp plate 5, a font set (not shown) can also be provided. in accordance with figure 1 with 3 In the example of , the stamp plate 5 is arranged in the stamping opening 6 at the bottom end of the housing 2 , ie the manual stamp 1 is displayed in a space-saving delivery position. In the imprinting position, the stamp plate 5 is not completely exposed, unlike in the delivery position; instead, the relief or printing relief of the stamp plate 5 lies in a plane with the underside of the housing 2, i.e. on the surface of the object to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com