Binder clip defect detection method and system based on deep learning

A defect detection and deep learning technology, applied in the field of image processing, can solve problems such as detection of asymmetrically deformed defective products, achieve good detection results and improve feature representation capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following is a detailed description of the embodiments of the present invention. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

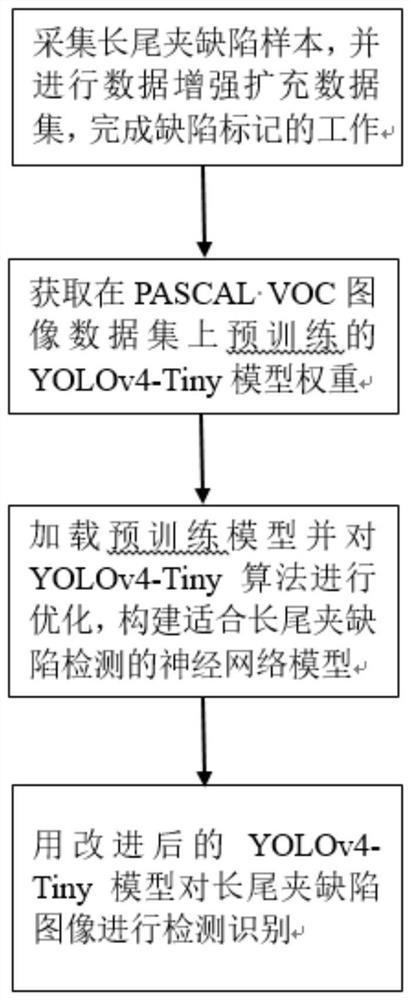

[0042] Such as figure 1 As shown, this embodiment provides a technical solution: a method for detecting defects of long tail clips based on deep learning, including the following steps:

[0043] S1: Collect defect samples of long tail clips, and perform data enhancement to expand the data set, and complete the work of defect marking;

[0044] Specifically, step S1 includes the following steps:

[0045] S11: collect data samples for experiments, and then divide the pictures into training set and test set;

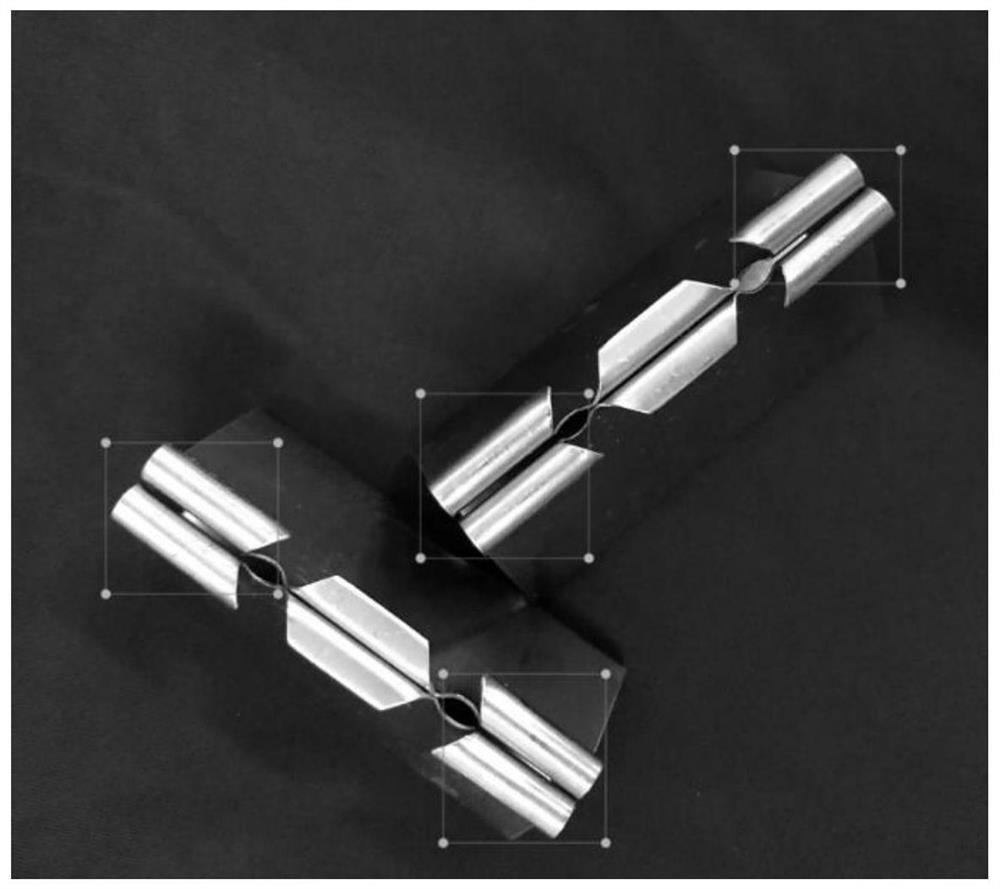

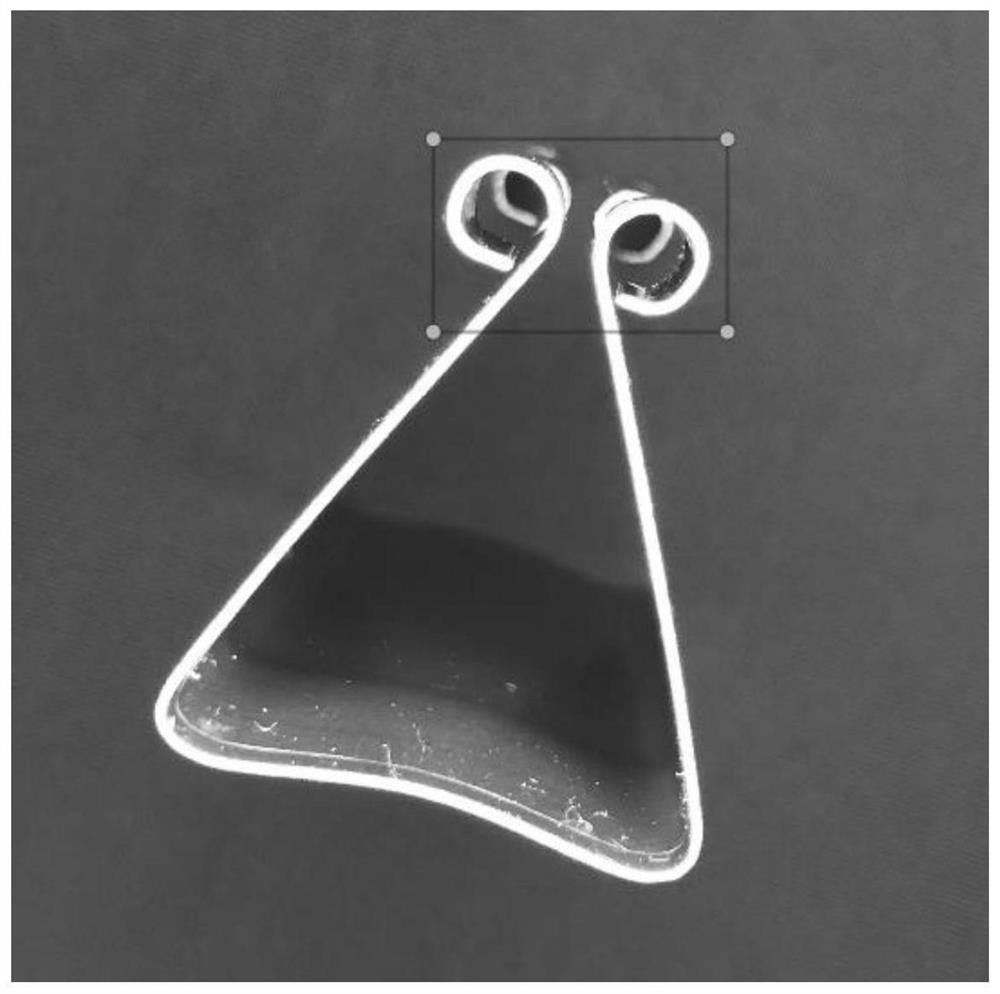

[0046] As shown in Figure 2, the image samples in the training set and the test set include tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com