Cable lap joint device

A technology of laps and cables, which is applied to the equipment, circuit, connection, etc. of connecting/terminating cables. It can solve the problems of water leakage at the terminals, misalignment of the cable cores at the terminals, and potential safety hazards, and achieve a waterproof safety factor. , the effect of improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

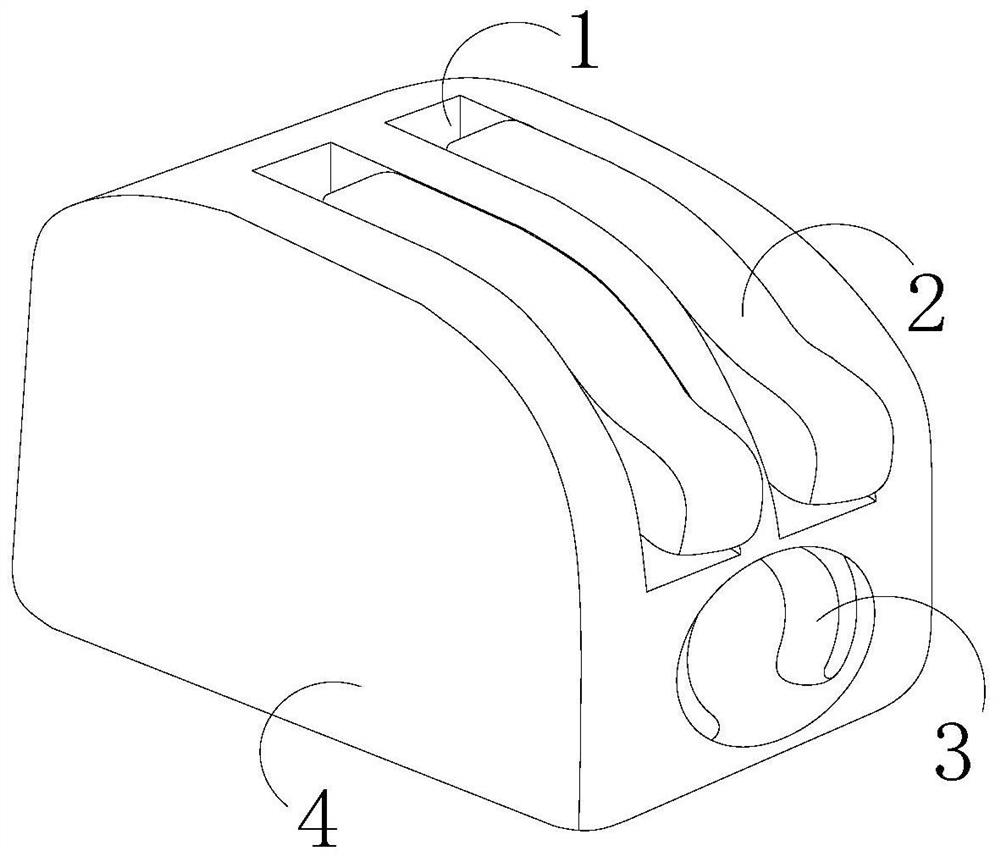

[0025] see Figure 1-Figure 5 , the present invention provides a cable splicer, the structure of which includes a fixing groove 1, a driving device 2, an overlapping end 3, and a housing 4, the fixing groove 1 is installed on the top of the housing 4, and the fixing groove 1 is embedded with The form is installed on the housing 4, the housing 4 is provided with an overlapping end 3, the overlapping end 3 penetrates the housing 4, the driving device 2 is connected with the overlapping end 3, the driving The device 2 is installed on the fixing groove 1 .

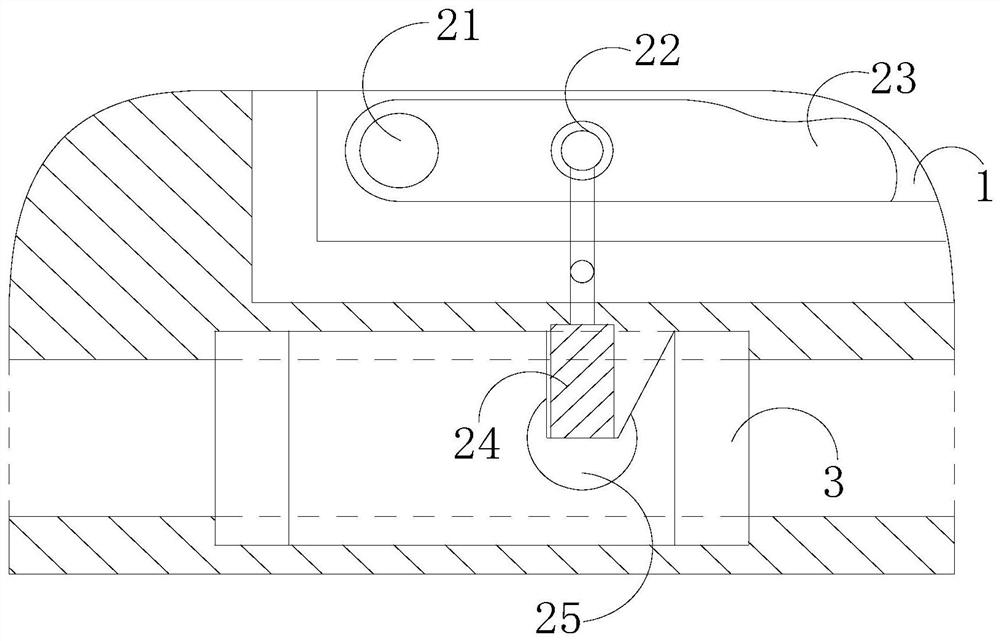

[0026] The driving device 2 is composed of a positioning shaft 21, a trailing end 22, a handle 23, an electric energy block 24, and a energization groove 25. The positioning shaft 21 runs through one end of the handle 23 and the handle 23 is installed in the fixing groove 1. The handle 23 is provided with a traction end 22, the traction end 22 is connected with the electric energy block 24, and the electric energy block 24 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com