A synchronous construction process of high-efficiency waterproof TPZ red core molecular adhesive waterproof membrane

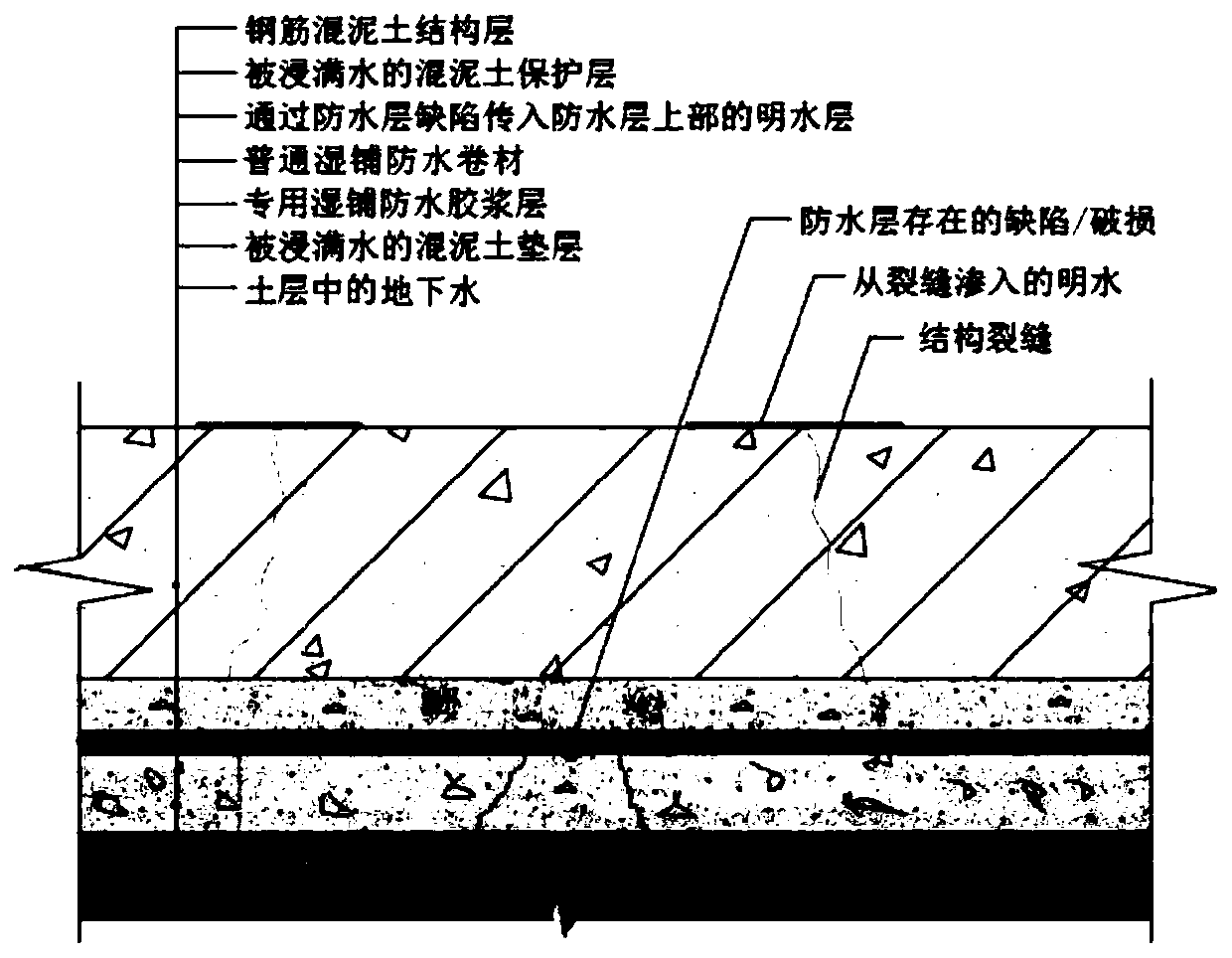

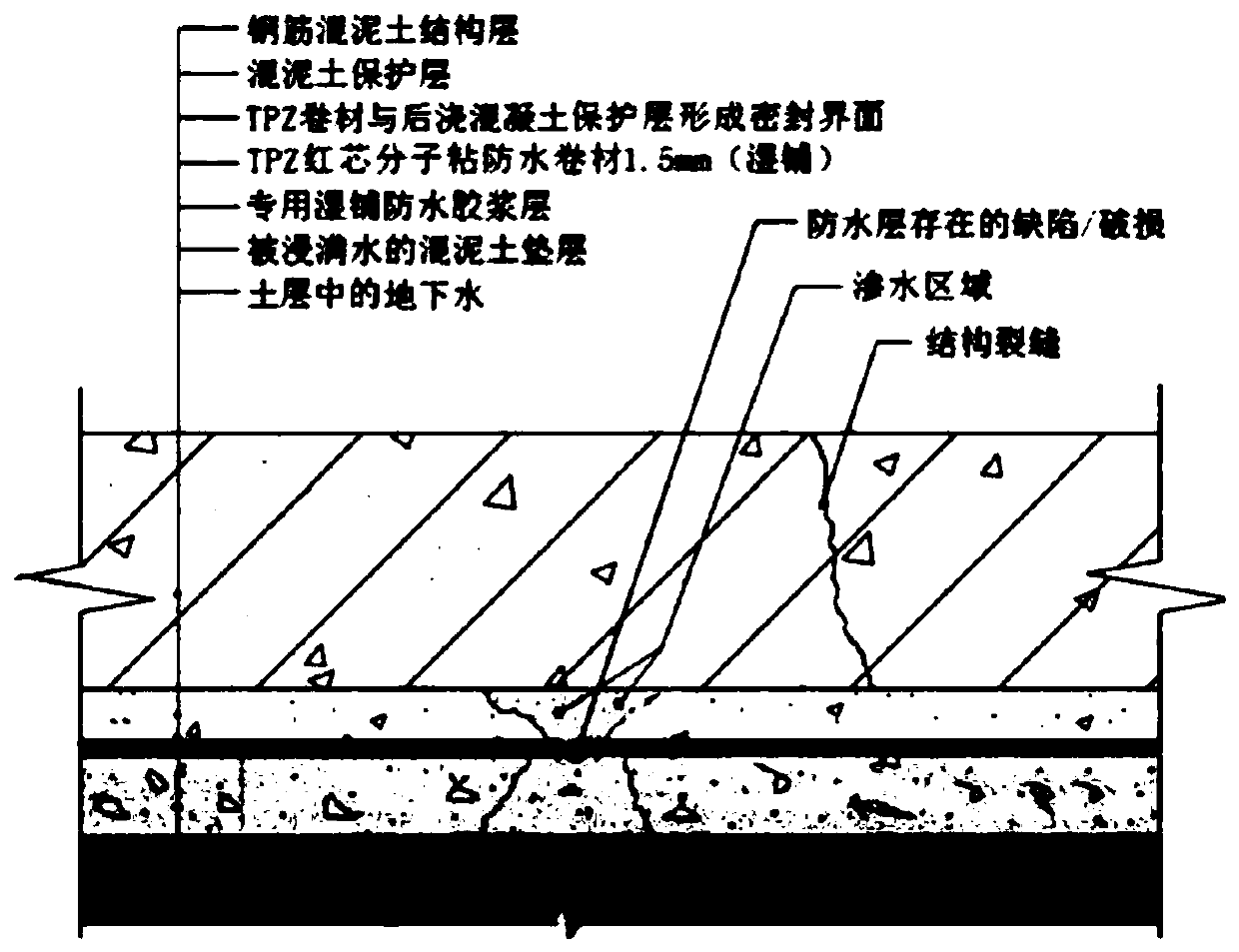

A waterproof membrane and simultaneous construction technology, applied in the direction of non-polymer adhesive additives, adhesives, adhesive types, etc., can solve the problems of long construction period of waterproof membrane, easy water channeling, low waterproof effect, etc. Achieve the effect of avoiding the overall failure of waterproofing, simple construction and improving waterproofness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A synchronous construction process of high-efficiency waterproof TPZ red core molecular adhesive waterproof membrane, the synchronous construction process includes the following steps:

[0037] (1) For the construction of concrete cushion, the surface needs to be leveled and calendered once, and the thickness of the cushion is 100-150mm;

[0038] (2) When the concrete surface can withstand the pressure of an adult's body weight, remove the TPZ red core molecular sticky waterproof membrane on the lower surface of the waterproof membrane, and use a special wet-paving waterproof glue to wet-pave the waterproof membrane; during the wet-paving process, the long and short sides It is connected together by lap joint, and the lap joint is bonded between the glue layer and the glue layer; when wet laying the membrane, for the whole piece of waterproof: use the whole piece of TPZ red core molecular adhesive waterproof membrane for wet laying, for the node As well as non-standard ...

Embodiment 2

[0048] The special-purpose wet-laying waterproof adhesive in Example 1 includes the following components in parts by weight: 60 parts of petroleum asphalt, 11 parts of reduced second-line naphthenic base oil, 6 parts of SBS rubber, 5 parts of SBR rubber, 3 parts of chloroprene rubber, nitrile butadiene 2 parts of rubber, 5 parts of aliphatic petroleum resin, 8 parts of heavy calcium powder.

[0049] Among them, the preparation process of special wet laying waterproof glue adopts the following steps:

[0050] S1 Open the heat-conducting oil valve of the reactor, pour in petroleum asphalt, reduce the second-line naphthenic base oil, and stir;

[0051] Add SBR rubber, neoprene and nitrile rubber at S2 temperature to 140°C, mix and stir, and stir at 200°C until completely melted;

[0052] S3 Add SBS rubber, stir, pass colloid mill once; add aliphatic petroleum resin, stir; after the petroleum resin is dissolved, add heavy calcium powder and stir to form a gel.

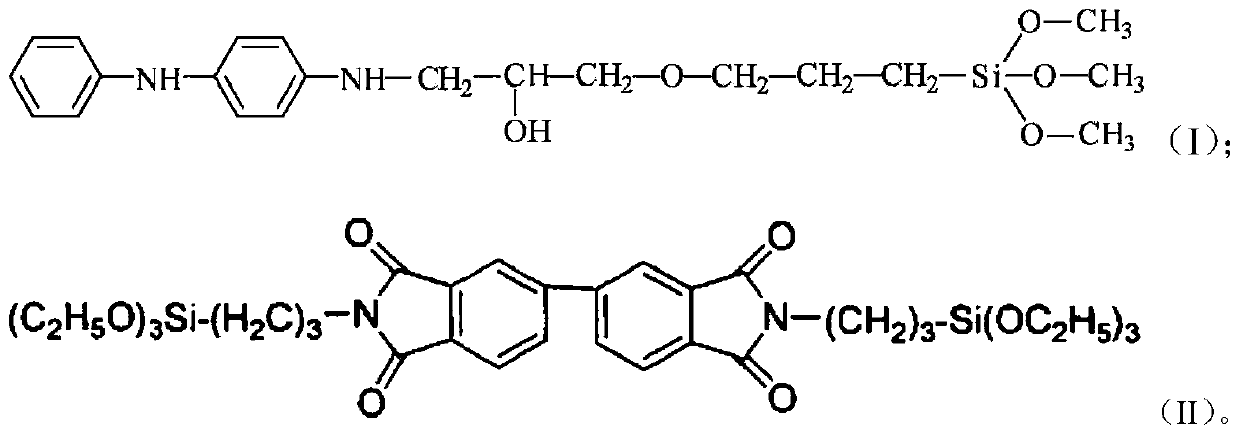

[0053] Among the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com