Double-seal plunger pressure relay

A double seal and relay technology, applied in the hydraulic field, can solve the problems of insufficient plunger support and poor sealing reliability, and achieve the effects of long service life, reliable sealing and improved action sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

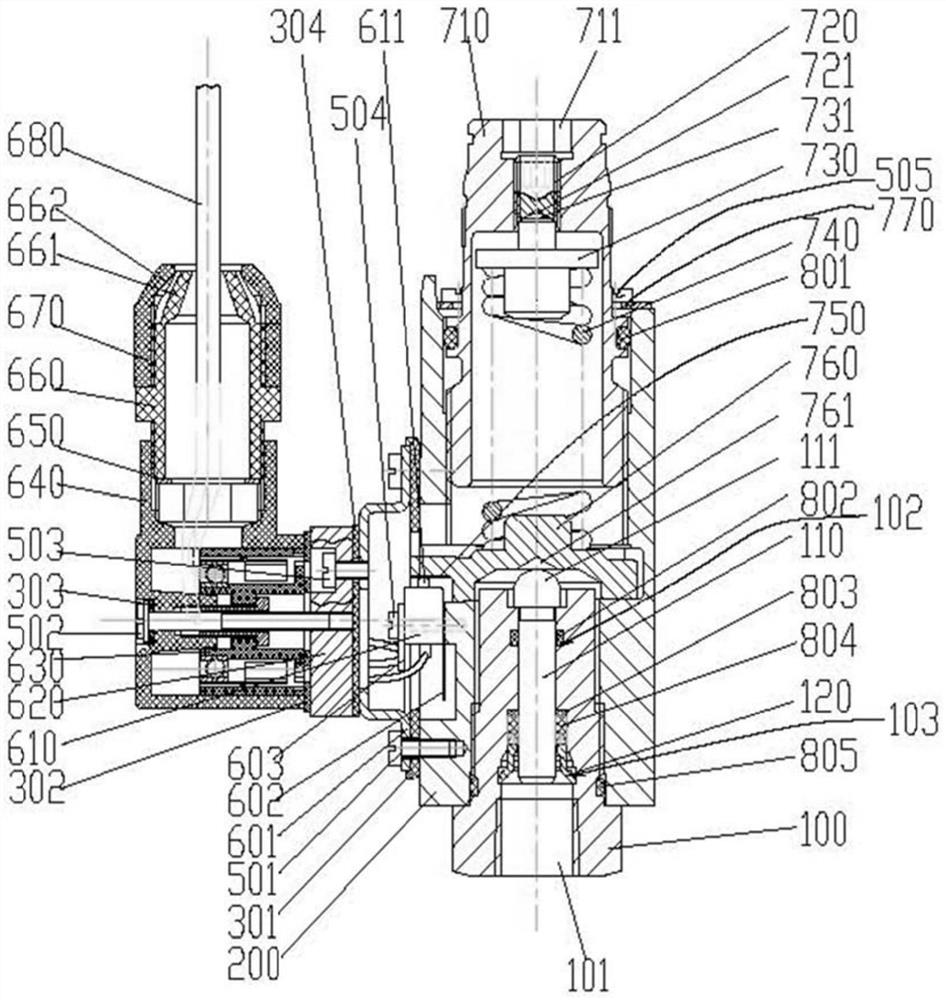

[0028] In view of the lack of support between the outer circle and the inner wall of the sleeve when the plunger is far away from the sealing ring in the existing relay, it is easy to rub against each other and cause mutual wear, which affects the action sensitivity and service life, and greatly reduces the working efficiency in the working process. This example solution provides a double-sealed plunger pressure relay on the basis of the prior art.

[0029] The steel sleeve is used as the main pressure-bearing part in the double-sealed plunger pressure relay, which is installed in the aluminum alloy shell, and the overall weight is light; at the same time, the Y-shaped sealing ring with a small contact area is used as the main part. For the seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com