Buckling lockrand type plate profile for building roof and roof system

A roofing system and roofing technology, which is applied to roofs, roofs, buildings, etc. that use flat/curved panels, can solve the problems of large roof leaks, roof system failure, and easy to be uncovered by strong winds, etc., to achieve beautiful architectural effects and deformation The effect of reducing the space and improving the wind resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings. The embodiments of the present invention are only used to illustrate the technical solutions of the present invention without limitation. Although the present invention has been described in detail with reference to the preferred embodiments, those skilled in the art should understand that the technical solutions of the invention can be modified or equivalently replaced , without departing from the spirit and scope of the technical solution of the present invention, all of which shall be covered by the claims of the present invention.

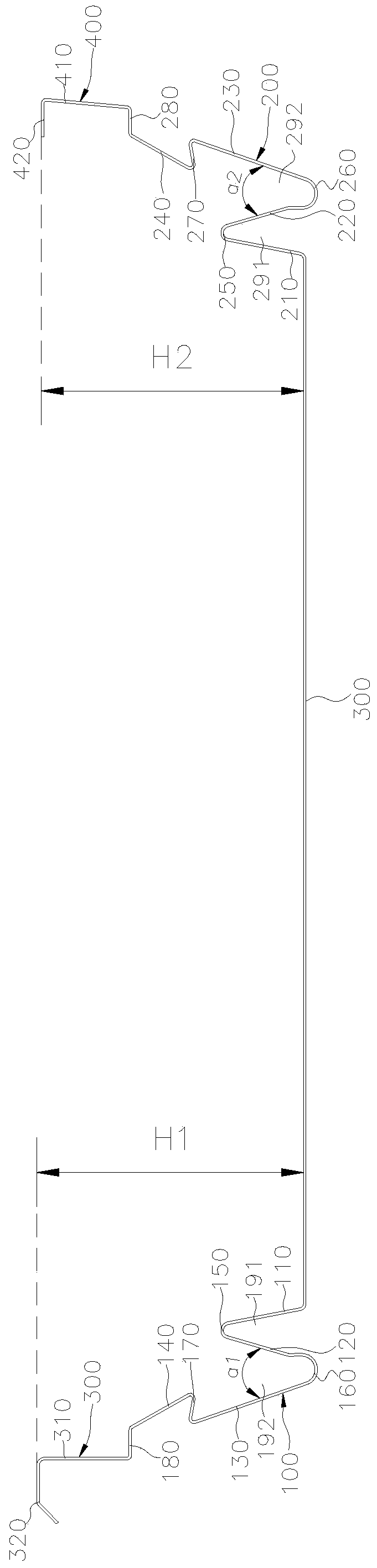

[0055] figure 1 It is a structural schematic diagram of an embodiment of the plate type of the present invention. Such as figure 1 As shown, the plate type of this embodiment is used as a plate for building a building roof system, and it includes a first fastening part 100 , a second fastening part 200 and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com