Manufacturing method for in-mold injection 3D coil product and 3D coil product

A technology of in-mold injection molding and manufacturing method, which is applied to coil devices, induction heating, etc., can solve problems such as intelligent and precise control of heat, air pressure and moisture, inability to perform precise temperature control, and low power density, and achieve reliable waterproofing. , good protection, high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

[0029] refer to Figure 1 to Figure 4 , in one embodiment, a method for manufacturing an in-mold injection molded 3D coil product, comprising the following steps:

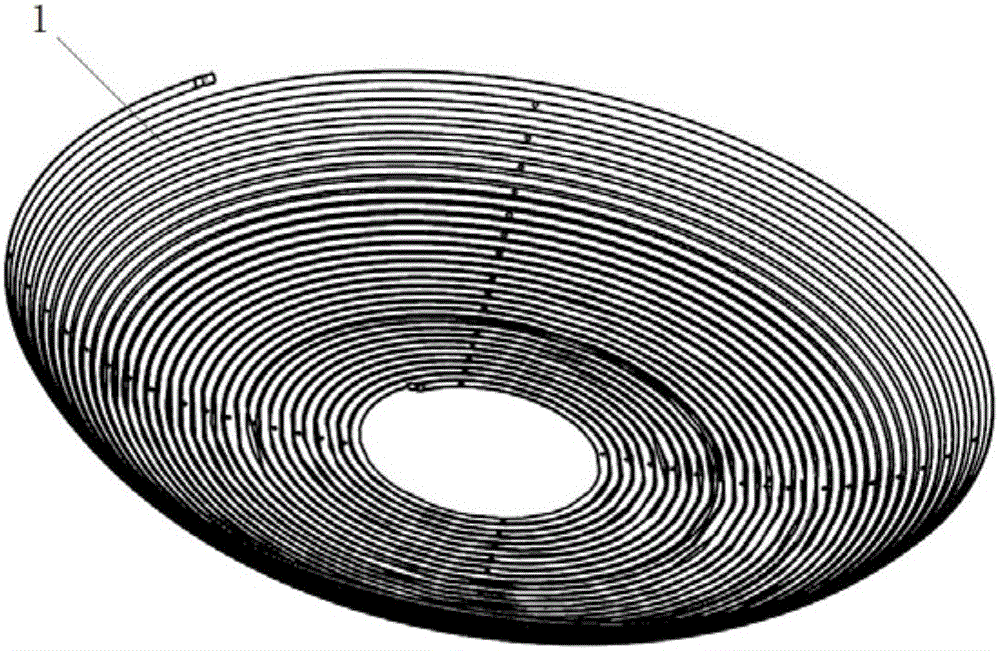

[0030] a. Process the metal material into a 3D coil 1 with a multi-circle surrounding distribution in the shape of a pot as a whole;

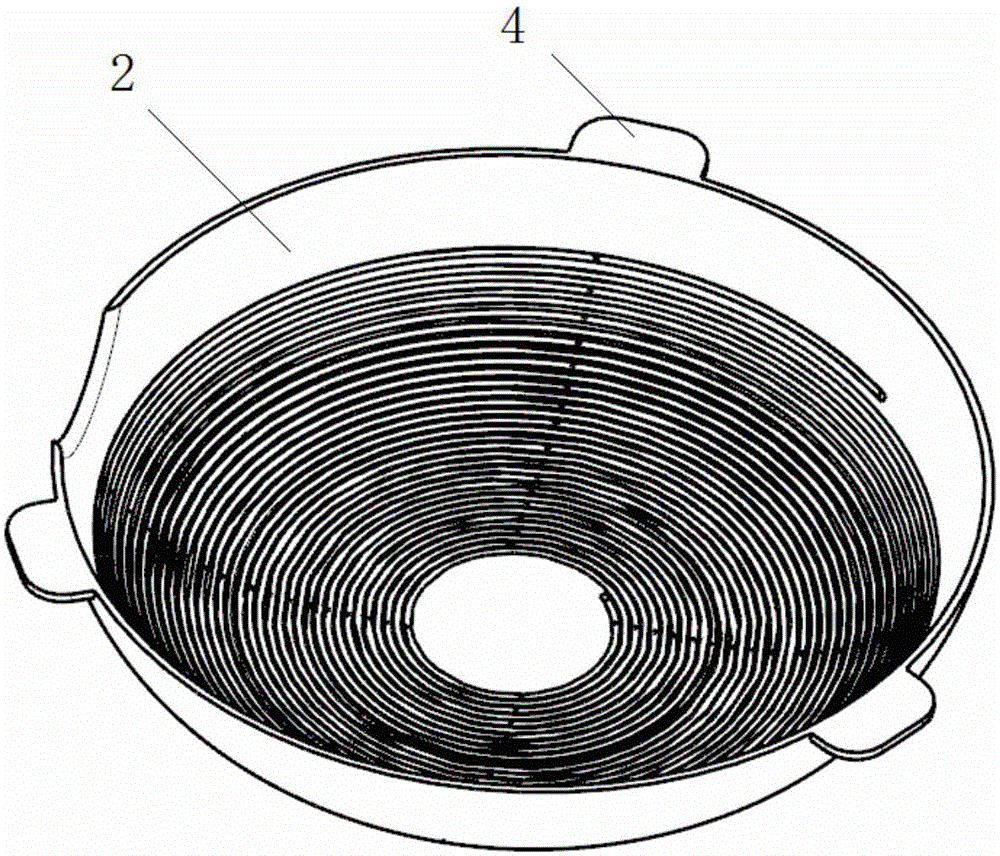

[0031] b. Injection molding the injection molded part 2 on one side of the 3D coil 1;

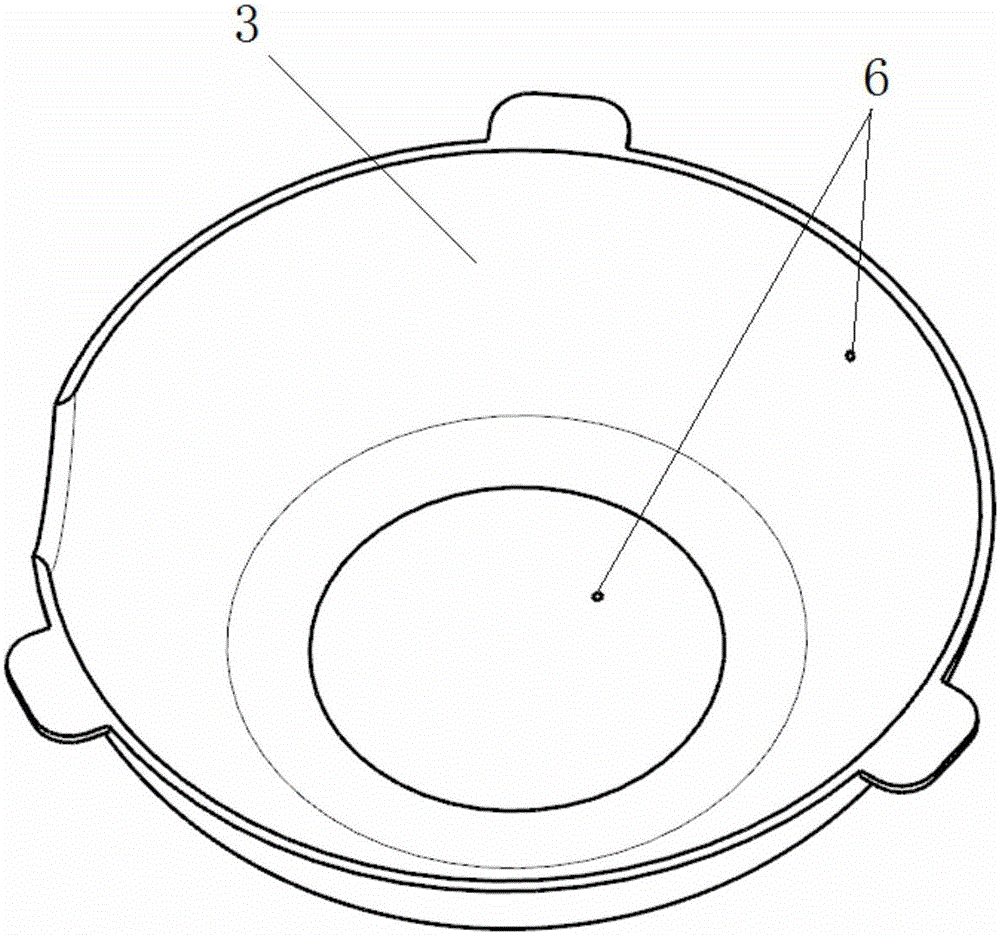

[0032] c. Perform secondary injection molding on the 3D coil 1 , and cover the 3D coil 1 with secondary injection molding material 3 , exposing only two contacts 6 as positive and negative poles of the coil.

[0033] In different embodiments, in step a, the 3D coils can be distributed in a circle with multiple turns (such as Figure 1-2 shown), square or polygonal, etc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com