Waterproof strip laminating device for wavy asphalt shingle

A technology for laminating devices and asphalt shingles, which is applied to devices that apply liquid to the surface, stone processing tools, working accessories, etc., and can solve the problems of large thickness, not particularly good elasticity, and difficulty in nailing waterproof nails.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

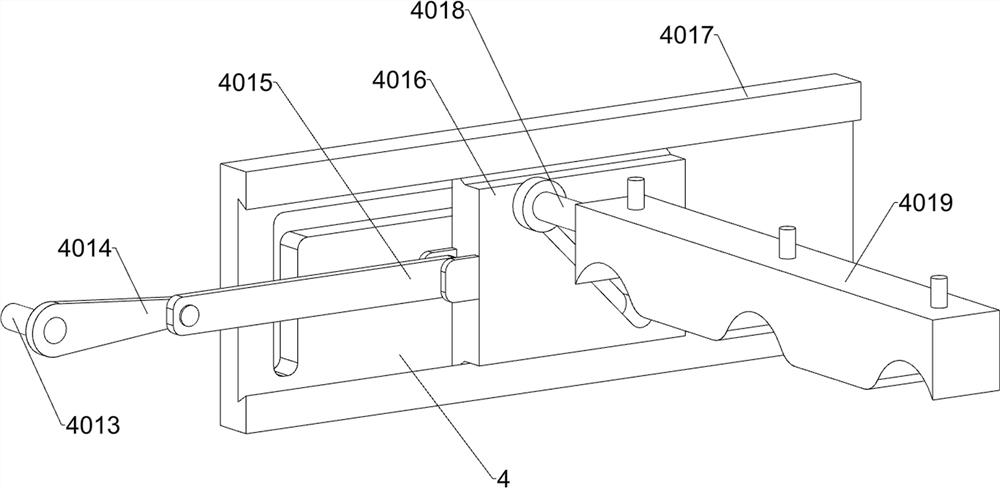

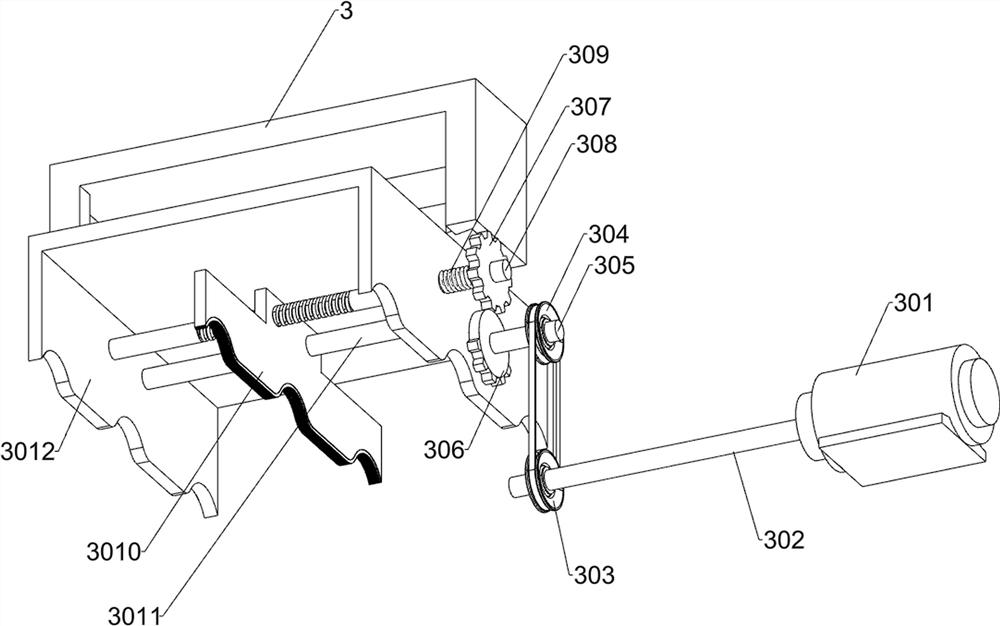

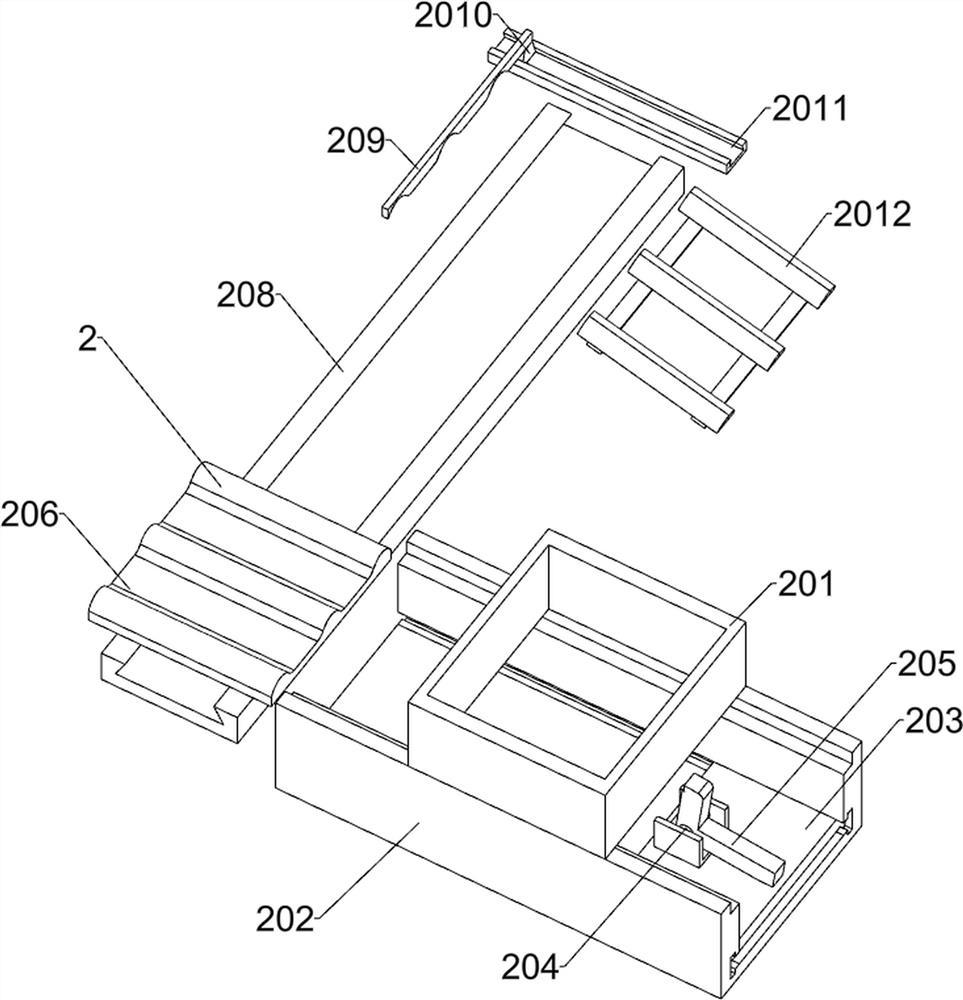

[0029] A waterproof strip bonding device for corrugated asphalt tiles, such as Figure 1-9 As shown, it includes a bottom frame 1, a material transfer unit 2, a gluing unit 3, a bonding and punching unit 4, a control panel 5, a collection box 6, a first bracket 7, a pillar 8, an anti-skid pad 9, and a second bracket 10 And the third bracket 11; the bottom frame 1 is connected with the material transfer unit 2; the bottom frame 1 is connected with the gluing unit 3; The underframe 1 is connected with the first support 7; the underframe 1 is connected with four pillars 8; the underframe 1 is connected with the second support 10; the underframe 1 is connected with the third support 11; the gluing unit 3 is connected with the The bonding and punching unit 4 is connected; the bonding and punching unit 4 is connected with the second bracket 10; the bonding and punching unit 4 is connected with the third bracket 11; the control panel 5 is connected with the first bracket 7; each Pil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com