Container floor and manufacturing method

A container and floor technology, applied in the field of container floor and manufacturing, can solve the problems of non-compliance, high cost, large wood consumption, etc., and achieve the effect of convenient fixing and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

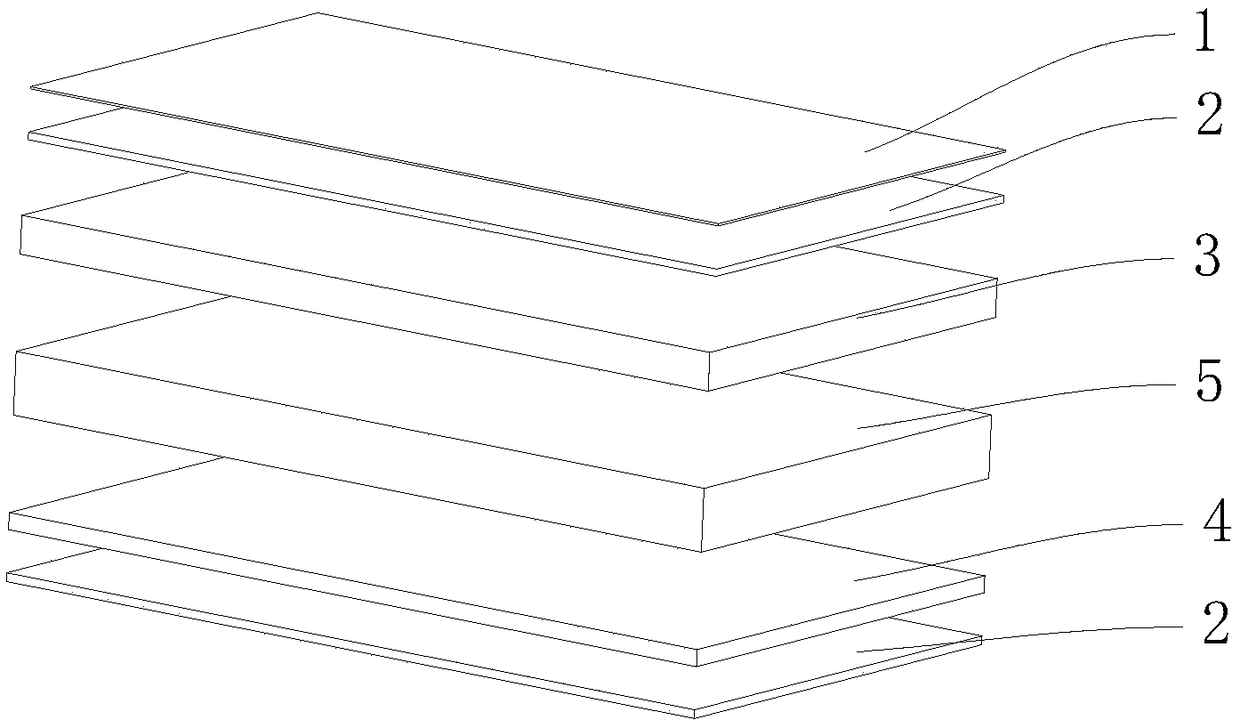

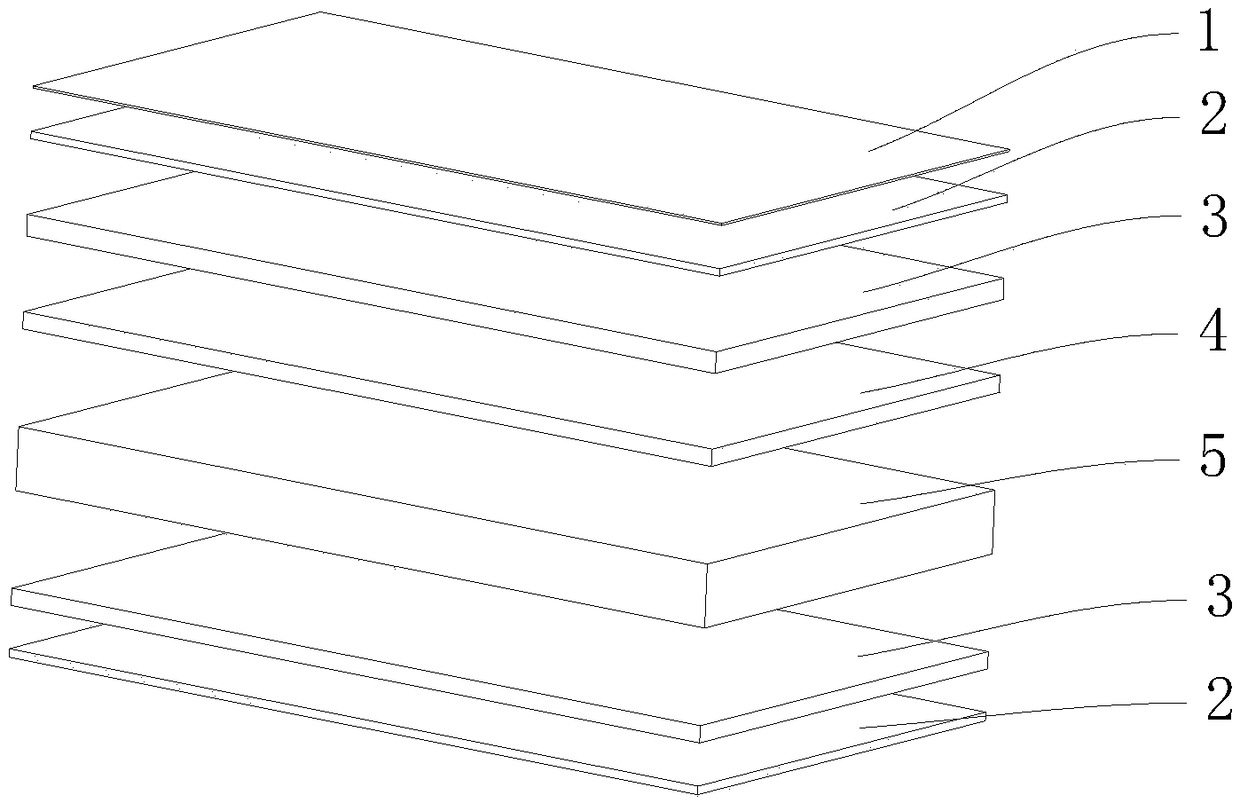

[0033] Embodiment 2: Different from Embodiment 1, the reinforcement layer includes a first reinforcement layer and a second reinforcement layer respectively located on both sides of the honeycomb structure layer 5, and the first reinforcement layer and the second reinforcement layer The thickness of the layer ranges from 0.5:1 to 3.5:1, preferably 2:1, the first reinforced layer is wood plywood layer 4 or bamboo plywood layer 3, and the second reinforced layer is wood plywood layer 4 or Bamboo plywood layer 3.

Embodiment 3

[0034] Embodiment three: different from embodiment two, the first reinforcement layer includes a first reinforcement layer and a second reinforcement layer, the first reinforcement layer is a bamboo plywood layer 3, and the second reinforcement layer is a wooden The plywood layer, the honeycomb structure layer 5 and the first reinforcement layer are located on both sides of the second reinforcement layer, and the thicknesses of the first reinforcement layer and the second reinforcement layer are equal to 4mm. Of course, this embodiment can also be based on the first embodiment.

Embodiment 4

[0035] Embodiment 4: Different from Embodiment 1, it also includes an anti-wear layer 1 located on the outside of the skin layer 2, and the anti-wear layer 1 is made of melamine material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com