Ash scraper for tile laying and use method

A technology of dust scraper and ceramic tile, which is applied in the direction of architecture and building construction, and can solve the problems of uncontrollable device level, uneven depth of tooth marks of dust scraper, gaps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

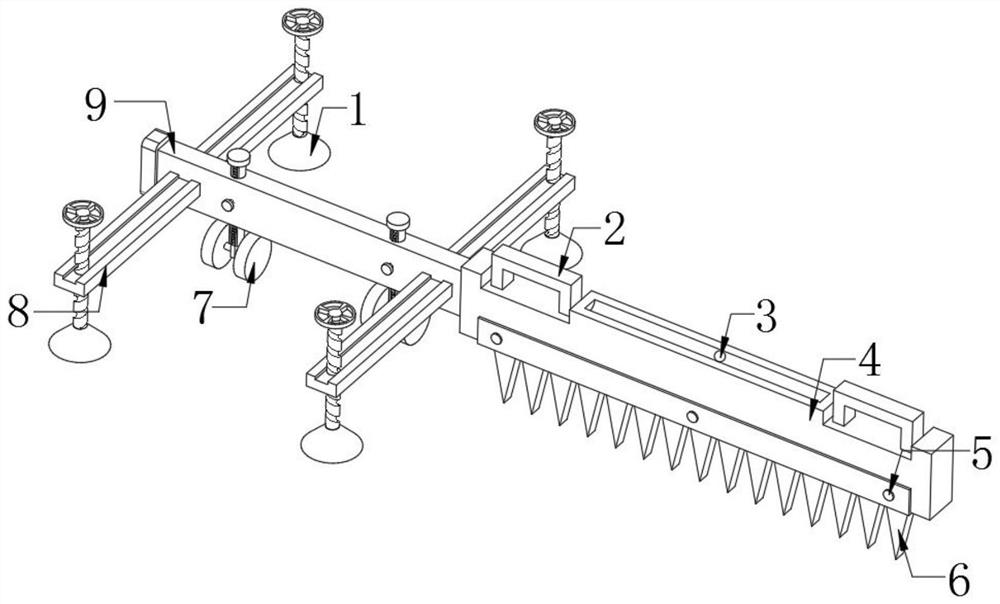

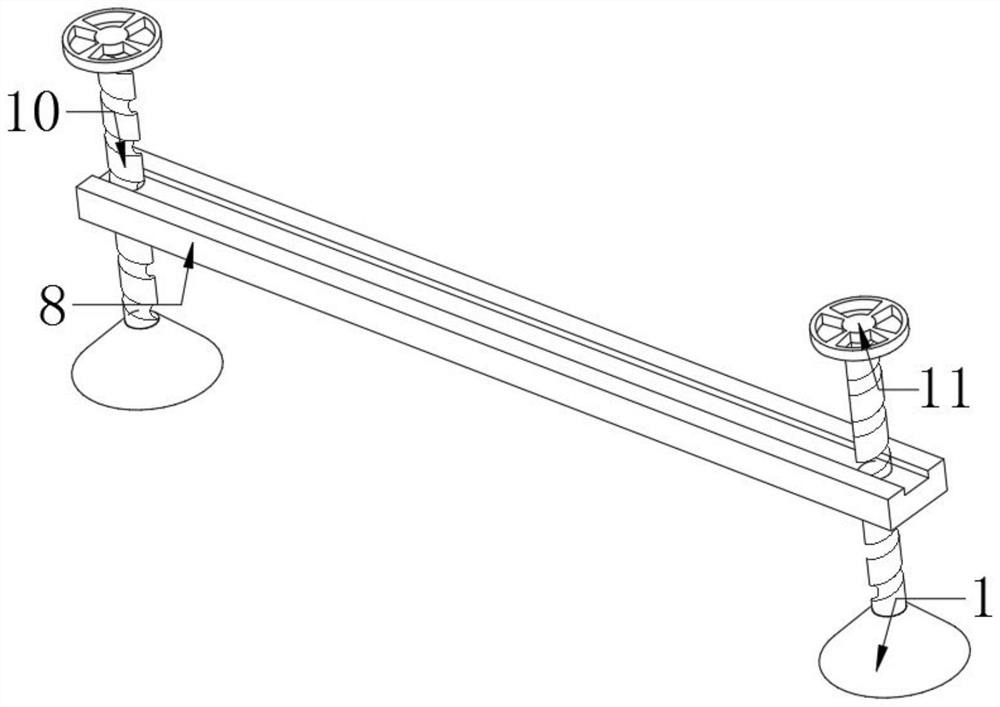

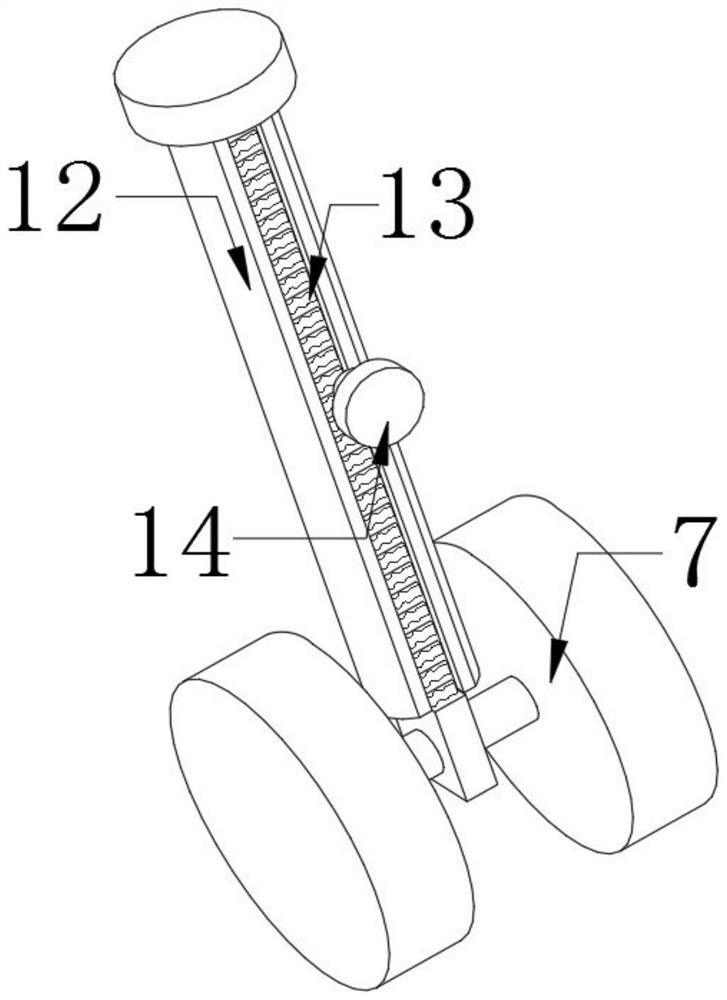

[0026] Embodiment 1: refer to Figure 1-4 , a dust scraper for tile paving, comprising an aluminum alloy scraper 4, one end of the aluminum alloy scraper 4 is fixed with a fixed rod 9 by a bolt, and both sides of the outer wall of the top of the fixed rod 9 are provided with adjustment holes for adjusting The inner wall of the hole is slidingly connected with a column 12, the bottom outer wall of the column 12 is connected with a roller 7 through a bearing, and both sides of the outer wall of the top of the aluminum alloy scraper 4 are provided with fixing grooves, and the inner wall of the fixing groove is fixed with a plastic handle 2 by bolts. The top outer wall of the aluminum alloy scraper 4 is provided with a level mechanism, and the outer wall of the aluminum alloy scraper 4 is fixed with a zigzag galvanized iron sheet 6 through a set screw 5. After the ground dry-mix mortar is laid, place the end of the tile dust scraper near the column 12 on the laid tile, place one e...

Embodiment 2

[0035] After the dry-mixed mortar is laid on the ground, place the end of the tile dust scraper close to the column 12 on the laid tile, place one end of the zigzag galvanized iron sheet 6 on the dry-mixed mortar, and adjust the position of the column 12 so that the sawtooth galvanized iron sheet 6 into an appropriate depth, adjust the aluminum alloy scraper 4 at the same time, adjust its level according to the bubble 3 of the spirit level, hold the plastic handle 2 and drag the scraper to form a uniform alveolar on the dry-mixed mortar, and then Use a trowel to evenly spread the cement mortar on the back of the tiles, lay the tiles on the dry-mixed mortar with alveoli, and tap them firmly with a rubber hammer. In this way, the tooth marks scraped out are relatively uniform in depth, and the tiles are more laid Tight, no air will be left between the tile and the mortar. When adjusting the level of the column 12 and the roller 7 through the horizontal air bubble 3, people can tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com