Low residual rate embossed release paper

一种离型纸、低残余的技术,应用在造纸、防粘纸、纸涂料等方向,能够解决胶面美化效果不理想、抗撕裂强度不高、不易观察胶面等问题,达到改善残余接着率、改善防静电性能、粘结力紧密的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

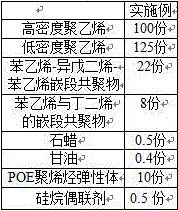

[0019] Embodiment: a kind of low residue sticking ratio embossed release paper, comprises polyester film layer and and is coated on the film coating layer on the polyester film layer surface, this film coating layer is opposite to the polyester film layer There is an embossed pattern area on the surface of the embossed pattern area, and a silicone release agent layer is coated on the surface of the embossed pattern area, and the coating layer is composed of the following components by weight:

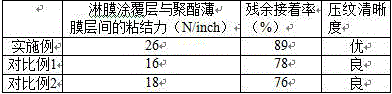

[0020] Table 1

[0021]

[0022] Above-mentioned POE polyolefin elastomer, embodiment 1 is the high polymer of ethylene and octene, embodiment 2 is the high polymer of ethylene and octene, embodiment 2 is the high polymer of ethylene and butene, embodiment 2 is High polymer of ethylene and butene, embodiment 2 is a high polymer of ethylene and octene.

[0023] The ratio of the above-mentioned styrene-isoprene-styrene block copolymer to the block copolymer of styrene and butadiene is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com