Manufacturing technology of mini type paper handkerchiefs

A manufacturing process and technology of paper handkerchiefs, applied in the field of manufacturing miniature paper handkerchiefs, can solve the problems of non-adjustable paper size, low production efficiency, high labor cost, etc. Coordinated smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings, but not as a limitation of the present invention.

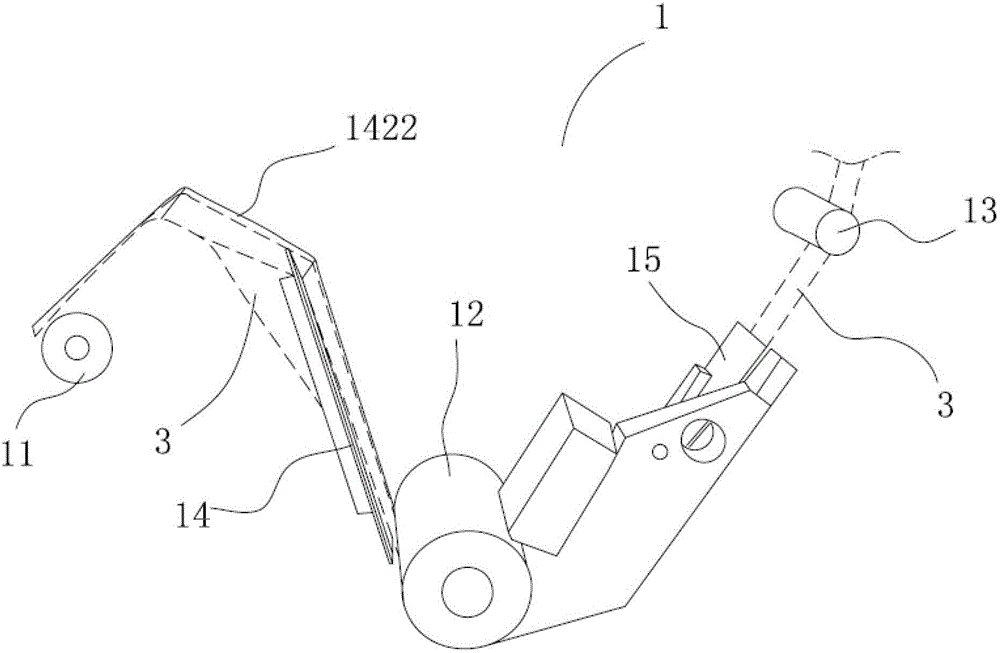

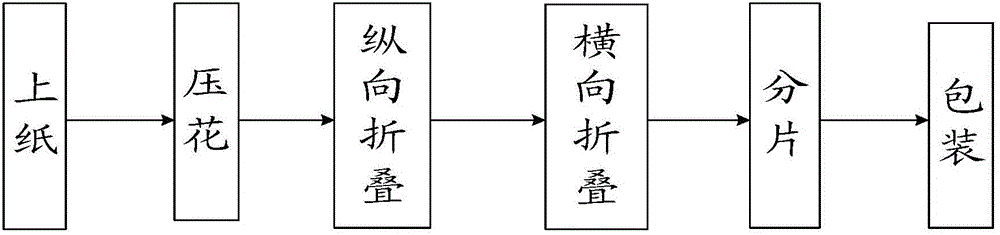

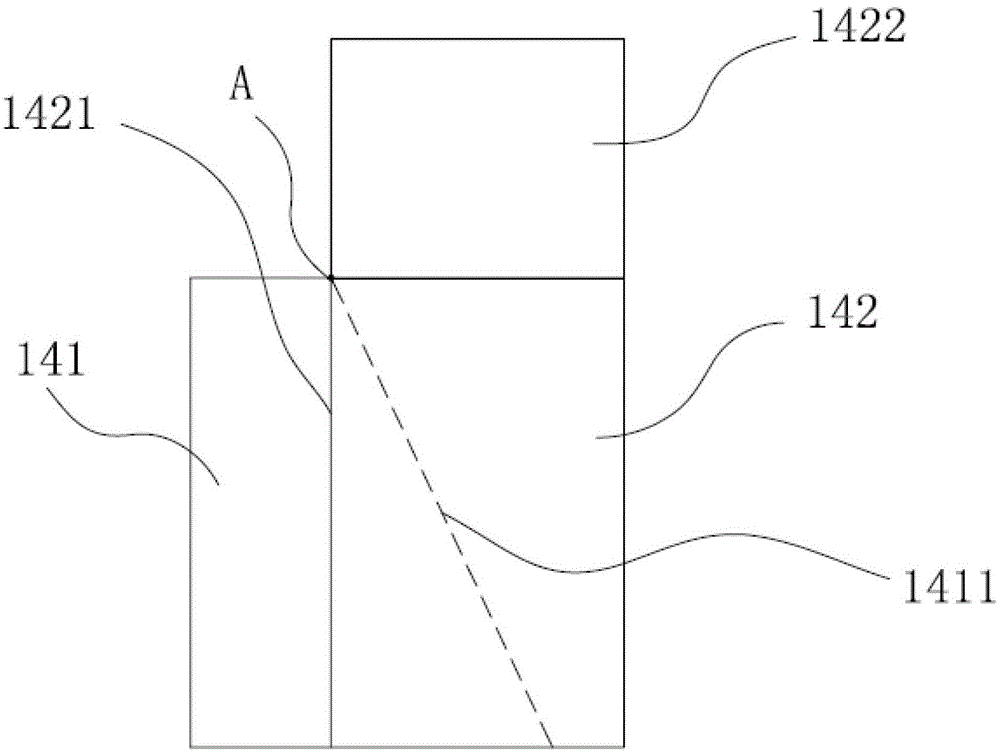

[0049] Such as figure 1 -A and Figure 10 As shown, the manufacturing process of the mini paper handkerchief according to the embodiment of the present invention includes the steps of paper loading, embossing, longitudinal folding, horizontal folding, slicing and packaging. Through the longitudinal folding unit 1, the transverse folding unit 2 and the flower plate unit 5 arranged successively on the machine table, the paper web 3 is tensioned and threaded on the longitudinal folding unit 1 and the transverse folding unit 2 in sequence, and the paper handkerchief passes through the longitudinal folding unit 1 and the transverse folding unit 2. The folding unit 1 is folded into three folding surfaces in a "Z" shape along the width direction, and then folded twice in half along the length direction by the transverse folding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com