Patents

Literature

30results about How to "Reduce manual procedures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

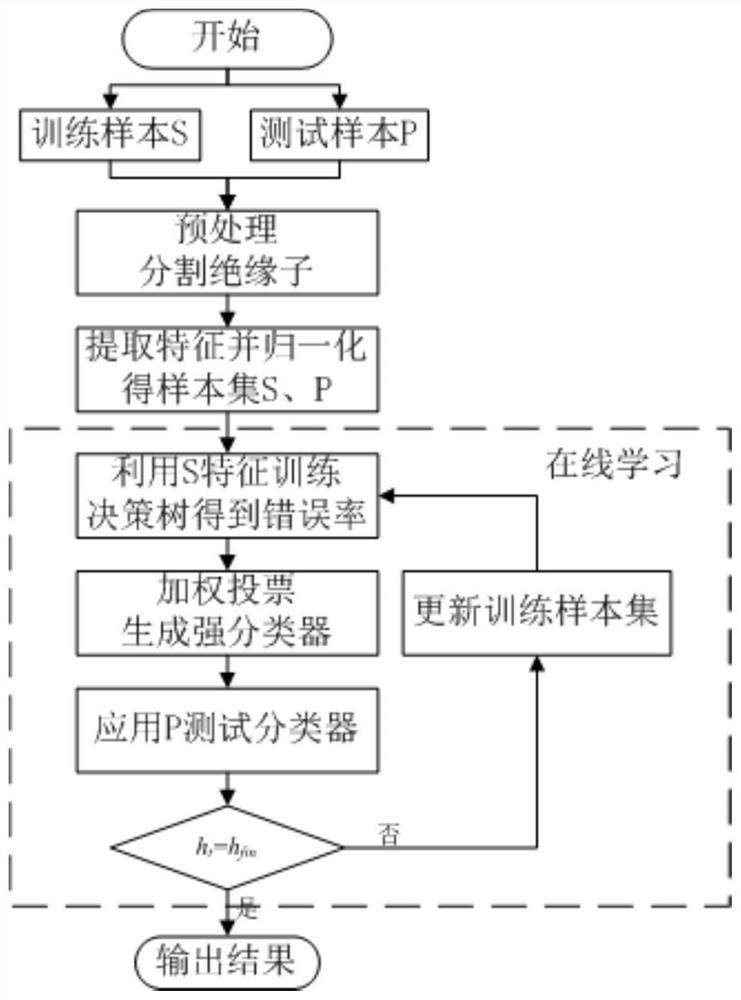

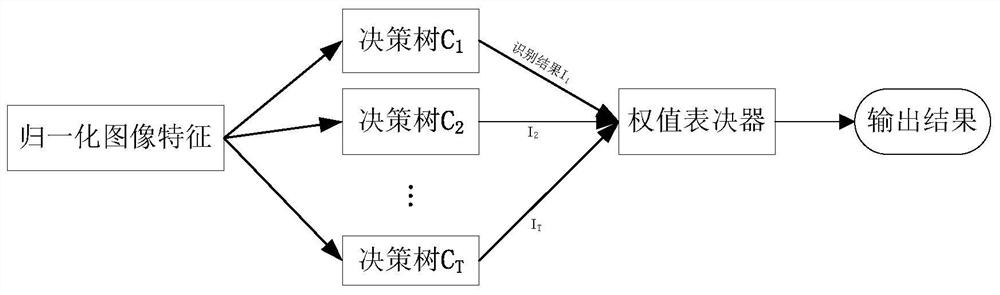

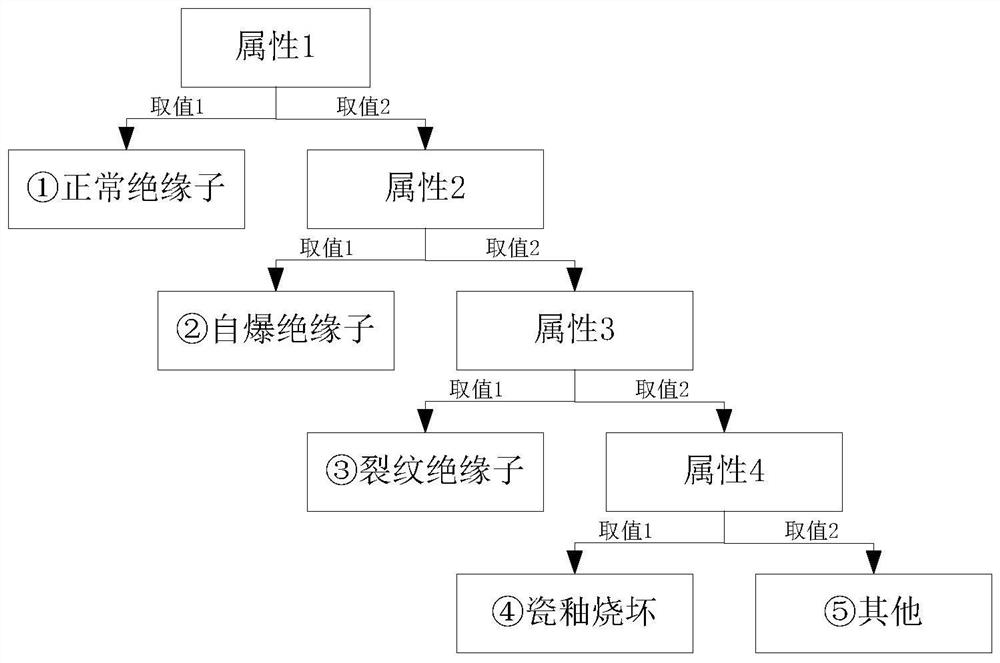

Insulator abnormal automatic detection method based on ensemble classifier online learning

ActiveCN108765373AImplement fault diagnosisReduce manual proceduresImage enhancementImage analysisOnline learningImage segmentation

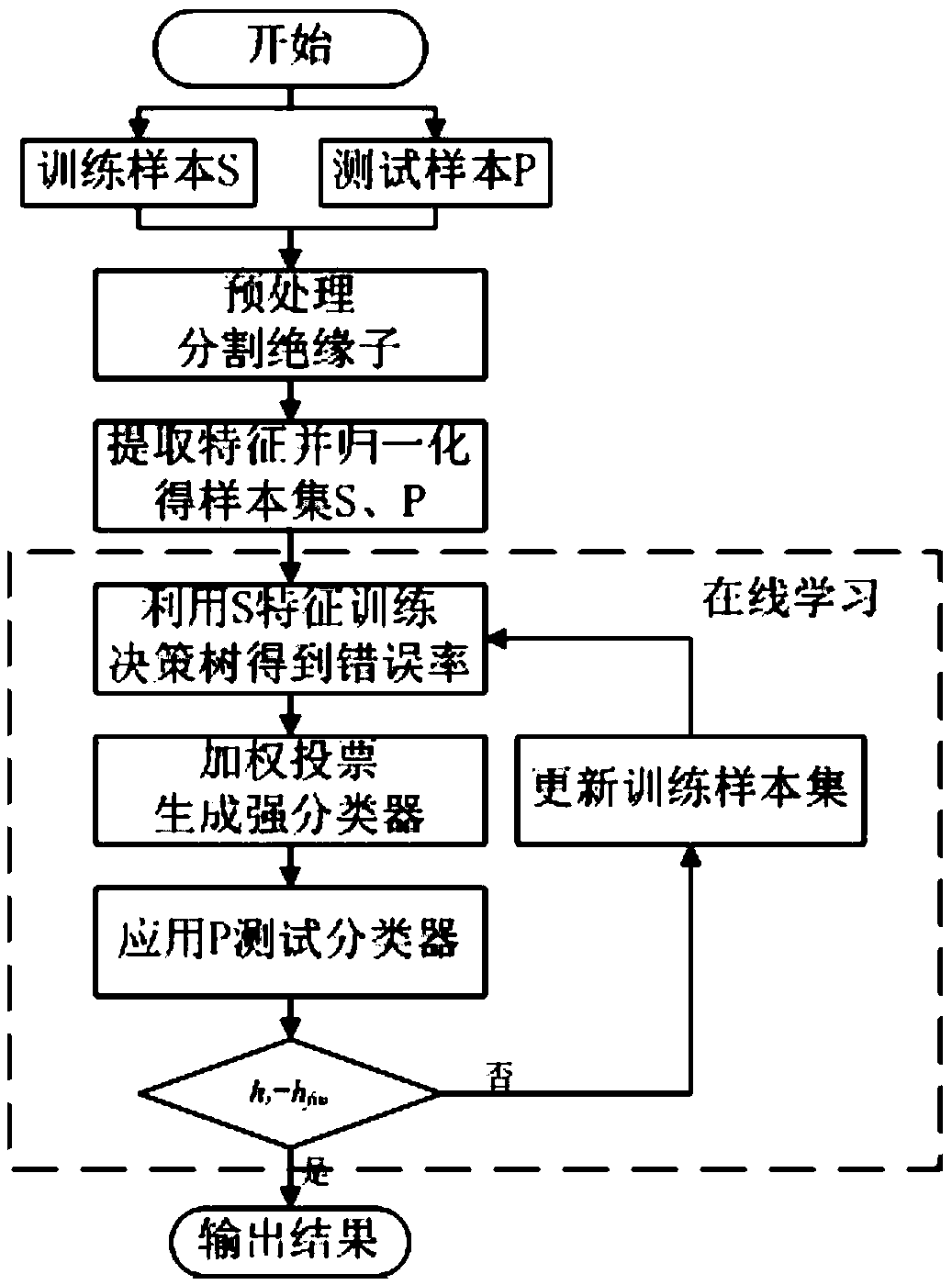

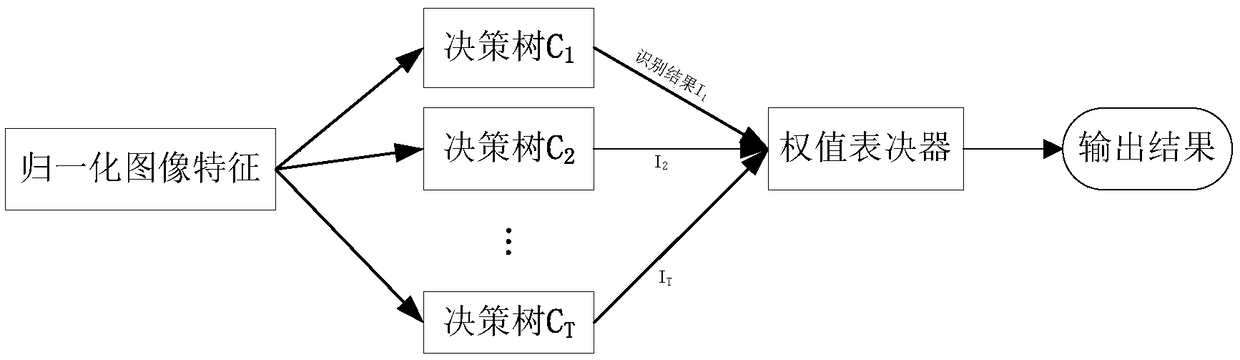

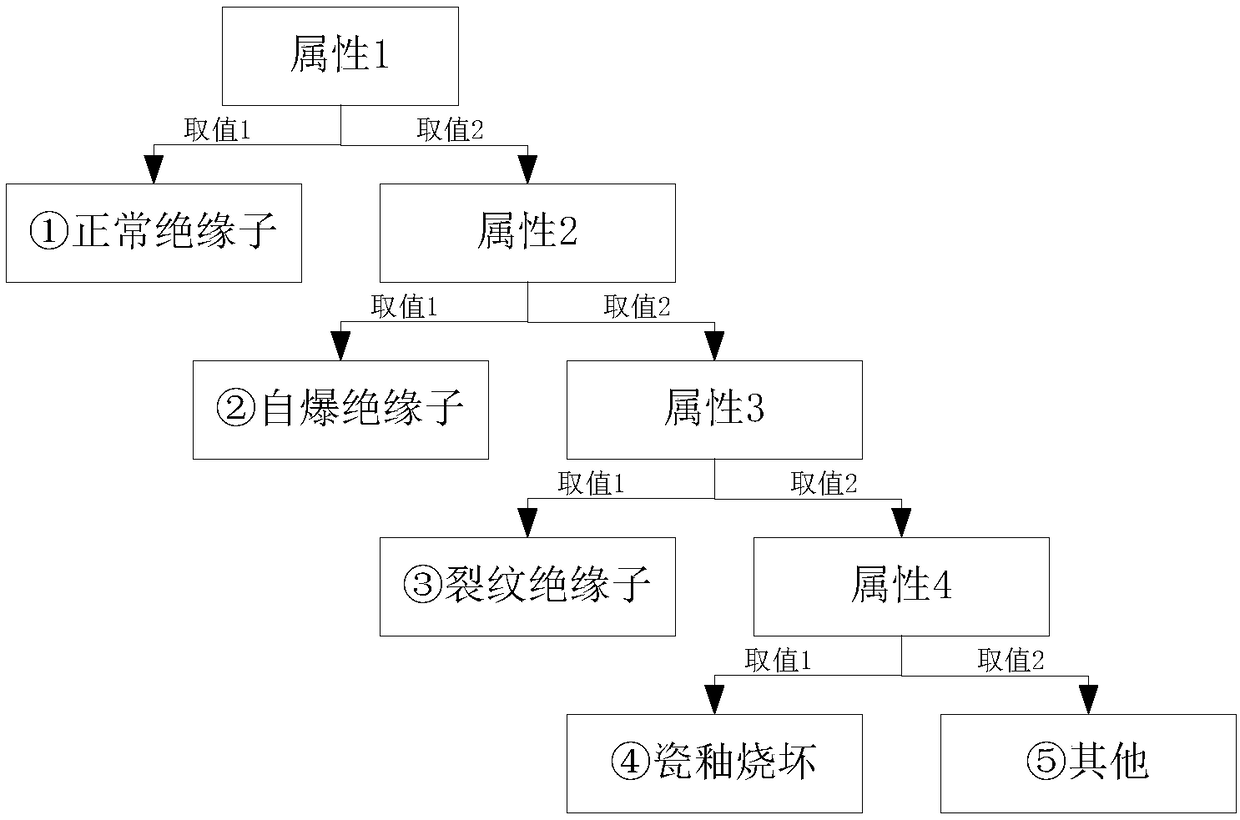

The invention discloses an insulator abnormal automatic detection method based on ensemble classifier online learning. The method comprises the following concrete steps of carrying a high-definition PTZ camera by using a unmanned aerial vehicle / pole tower as a carrier; shooting a power transmission line visible light insulator image; performing preprocessing, image division, image multi-feature extraction and the like on the obtained image to obtain various typical features of abnormal isolator images and to perform normalization processing; next, selecting decision trees to be used as a weakclassifier; using the normalization features as the classification attribute to train the weak classifier; performing repeated training to obtain a plurality of decision trees and the classification weight; finally, generating a strong classifier with high classification accuracy through weighted voting; meanwhile, timely updating the strong classifier by combining the online learning technology;and separating each type of abnormal insulator images for subsequent processing. The method has the advantages that the principle is simple and visual; the implementation is easy; the image processingtechnology and the machine learning algorithm are combined for intelligently recognizing the insulator abnormality; and a novel idea and method is provided for the insulator abnormal operation monitoring.

Owner:XI'AN POLYTECHNIC UNIVERSITY

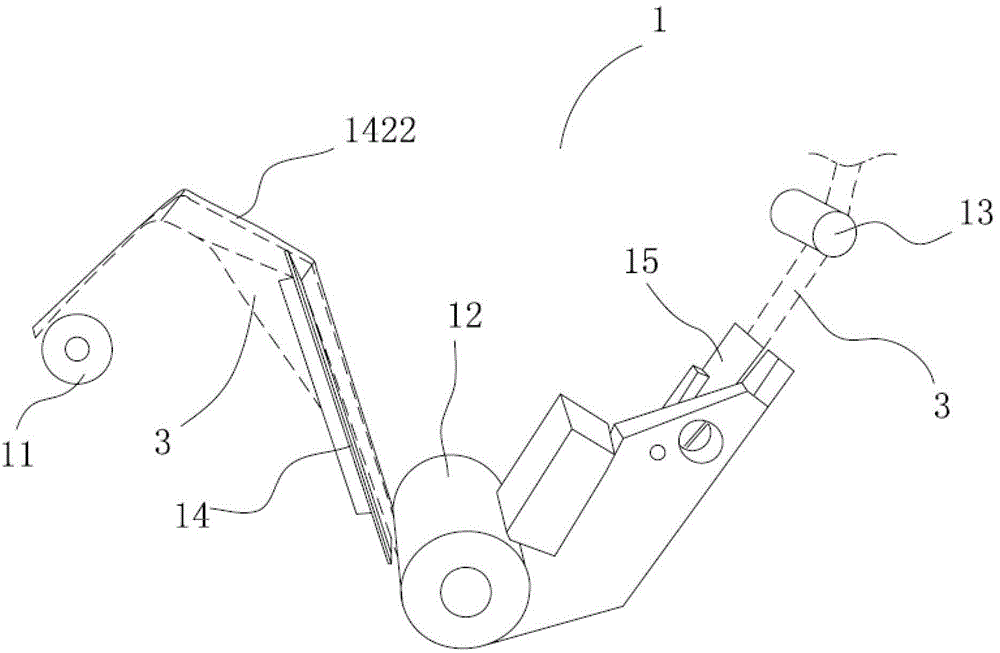

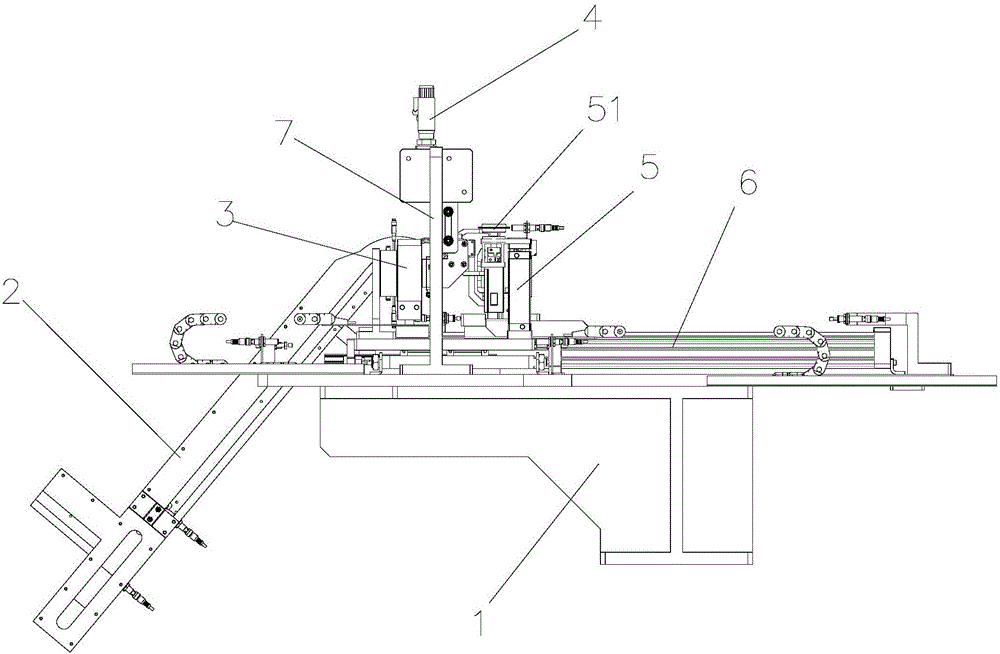

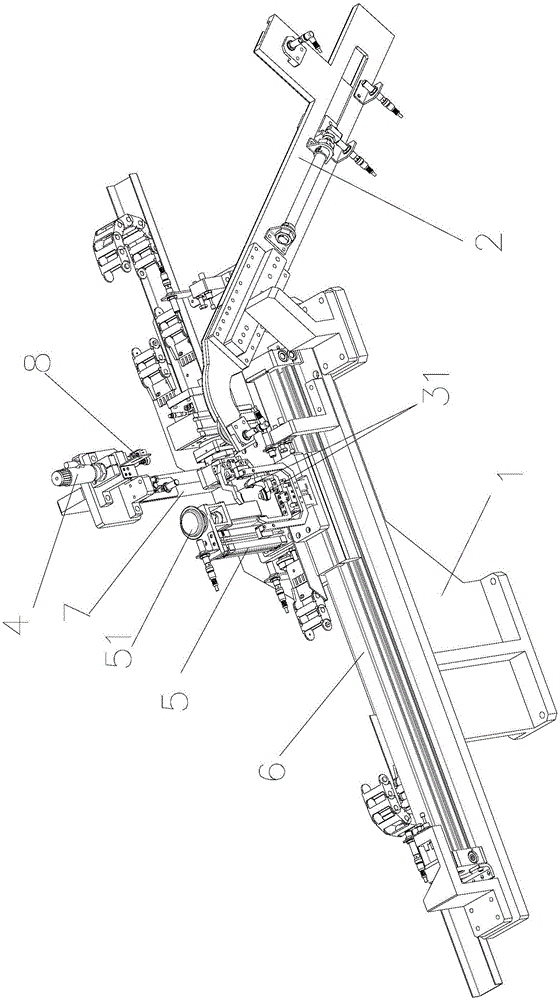

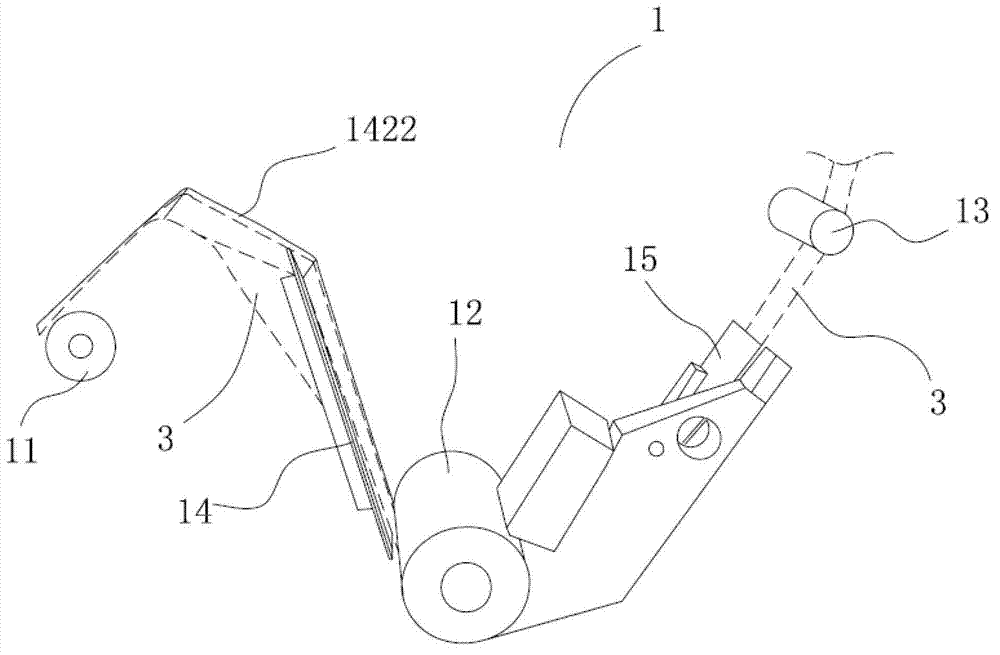

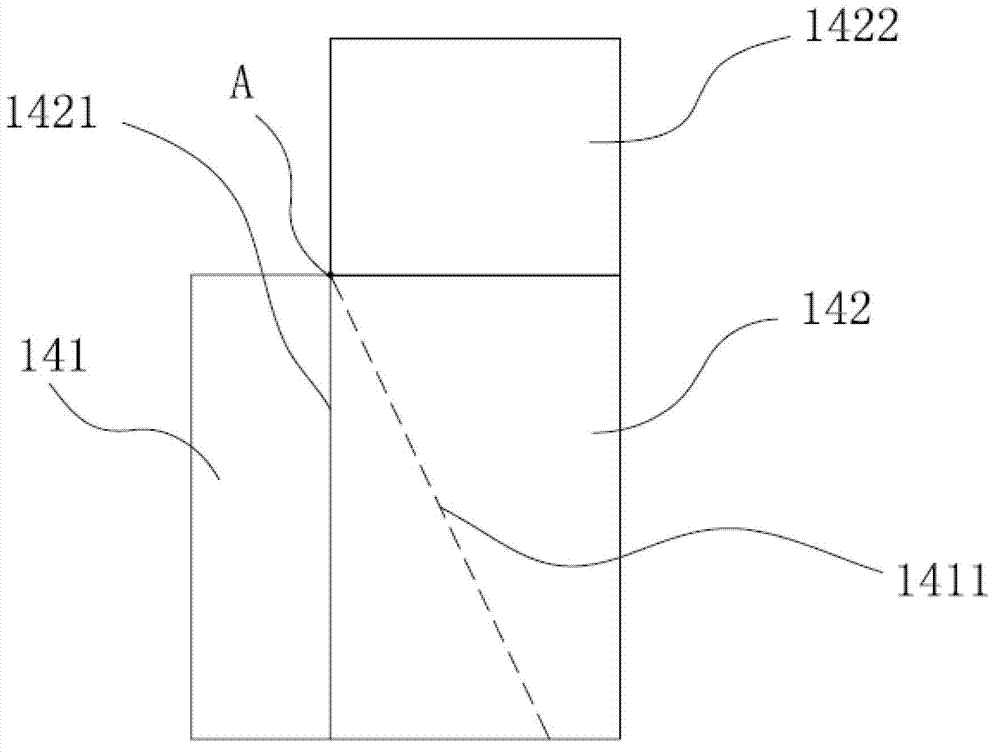

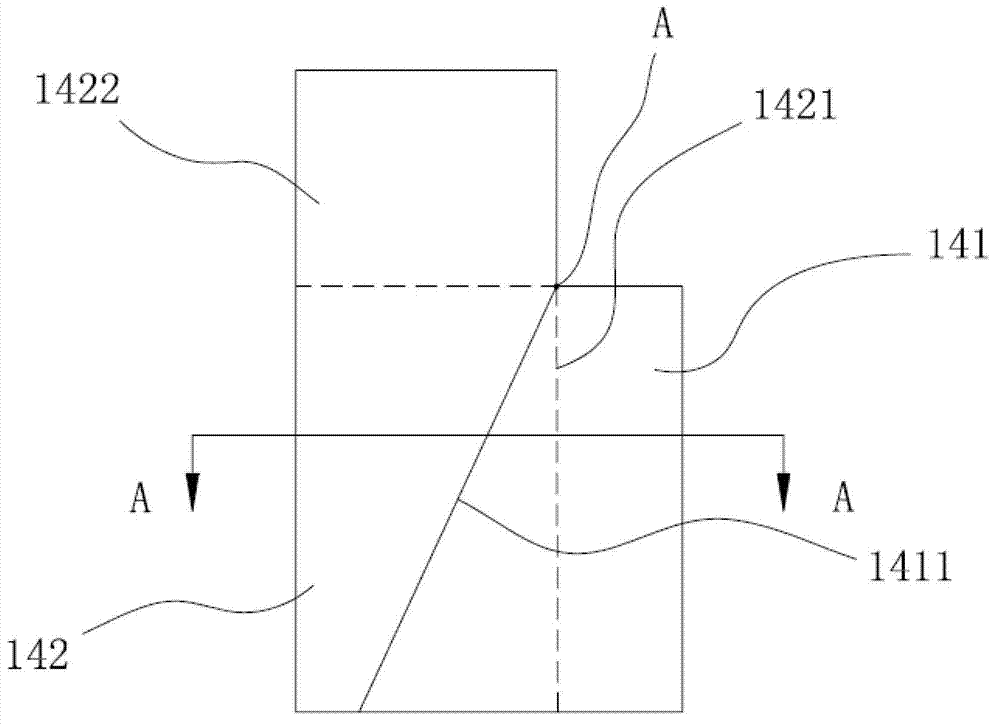

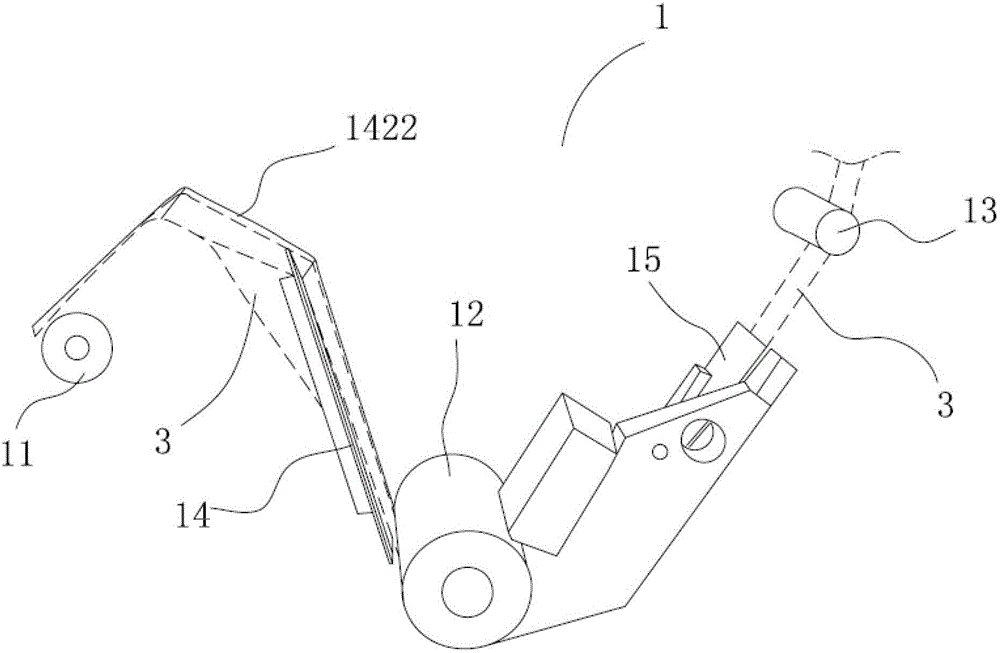

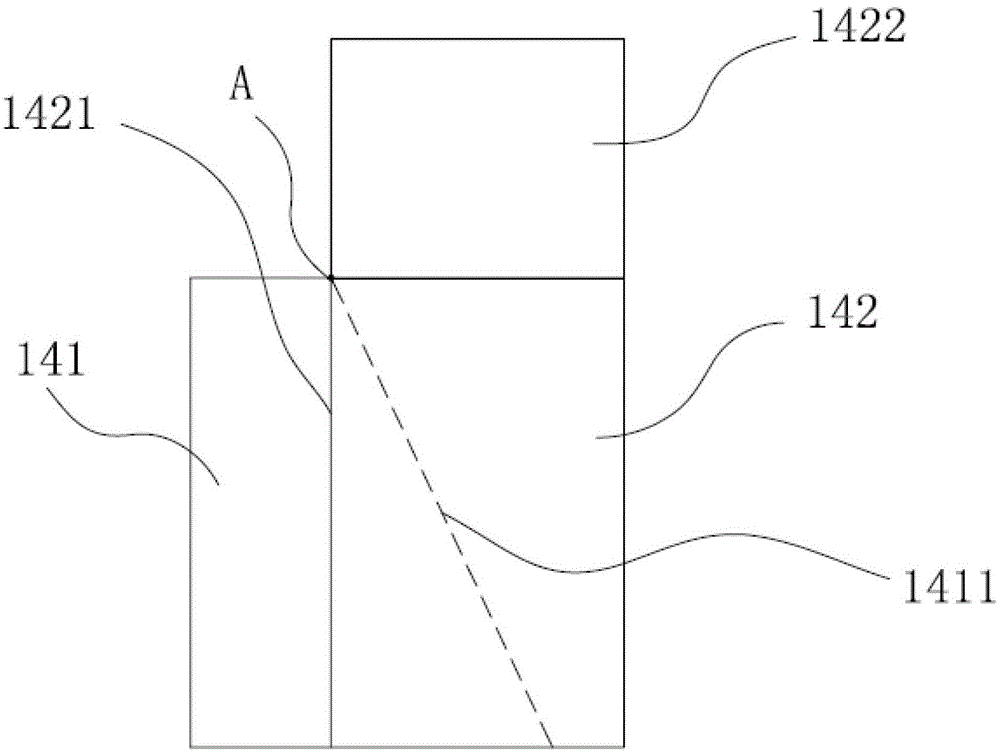

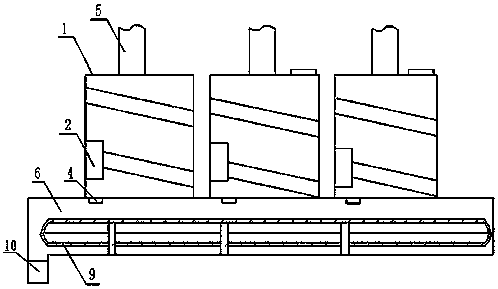

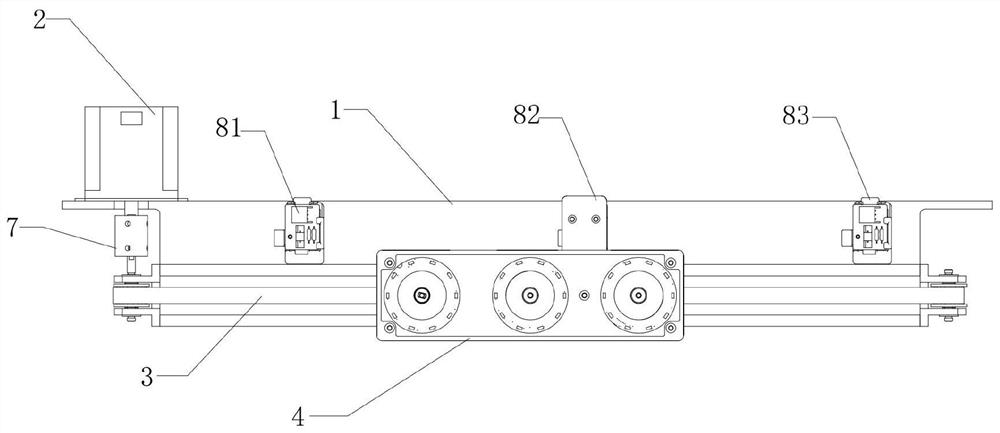

Paper handkerchief folding machining device

ActiveCN103332525AQuality improvementEasy to operateFolding thin materialsArticle deliveryPulp and paper industry

The invention discloses a paper handkerchief folding machining device. The paper handkerchief folding machining device comprises a longitudinal folding machine set, a transverse folding machine set and a flower plate machine set, wherein the longitudinal folding machine set, the transverse folding machine set and the flower plate machine set are sequentially jointed on a machine platform. Paper webs are sequentially arranged on the longitudinal folding machine set and the transverse folding machine set in a tensioning and penetrating mode. A paper handkerchief is folded into three folding surfaces in a Z-shaped mode in the width direction through a longitudinal folding machine, and refolded twice in the length direction to form four folding surfaces through a transverse folding machine. The paper handkerchief folding machining device is high in production efficiency and in speed and capable of reducing production cost. The size of produced paper can be adjusted, and products are convenient to carry and exquisite.

Owner:中顺洁柔(云浮)纸业有限公司

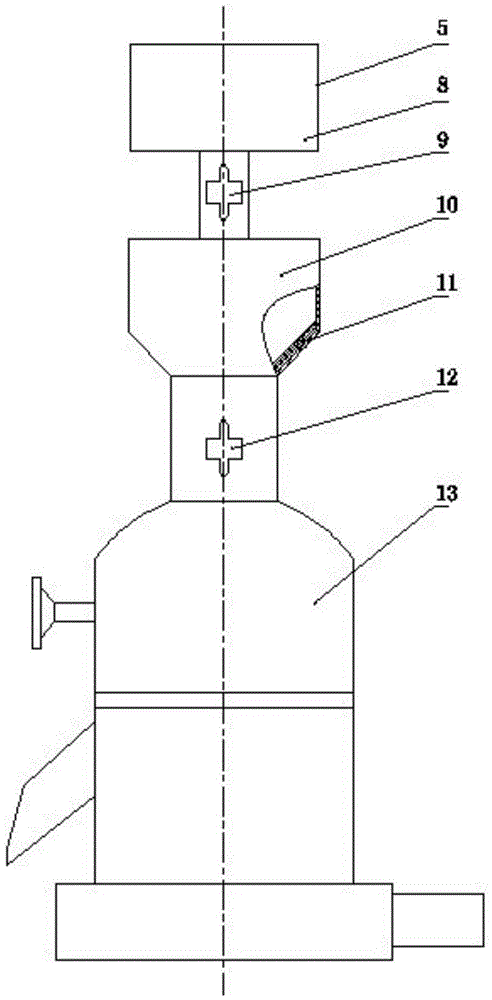

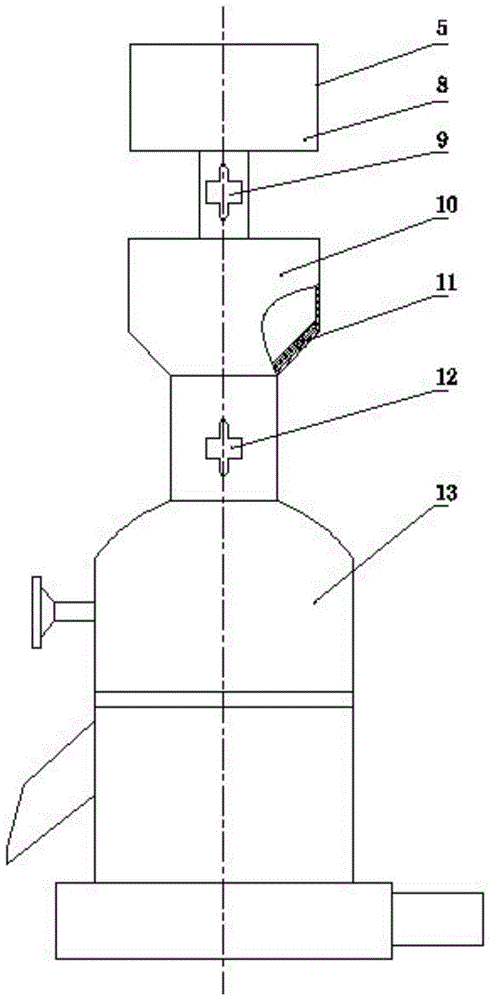

Flour production system

ActiveCN104689878AUniform qualityAchieve high integrationCocoaGrain treatmentsQuality levelMillstone

The invention relates to a flour production system. The flour production system comprises a grain storing silo, a first section material lifting machine, a wheat sorting screening machine, a second section material lifting machine, a wheat peeling device, a third section material lifting machine and a millstone flour mill, which are arranged in sequence. A discharging end of the grain storing silo is connected with an input end of the first section material lifting machine, an output end of the first section material lifting machine is connected with an input end of the wheat sorting screening machine, an output end of the wheat sorting screening machine is connected with an input end of the second section material lifting machine, an output end of the second section material lifting machine is connected with an input end of the wheat peeling device, an output end of the wheat peeling device is connected with an input end of the third section material lifting machine, and an output end of the third section material lifting machine is connected with an input end of the millstone flour mill. The flour production system is simple in structure and scientific and reasonable in design. According to the flour production system, the flour production process and the processing process are integrated together, the high integration of flour production is achieved, the time and the labor are saved, plenty of manpower and material power are saved, the working efficiency is improved, and the product quality level is improved.

Owner:LIXIN DONGHUA FLOUR

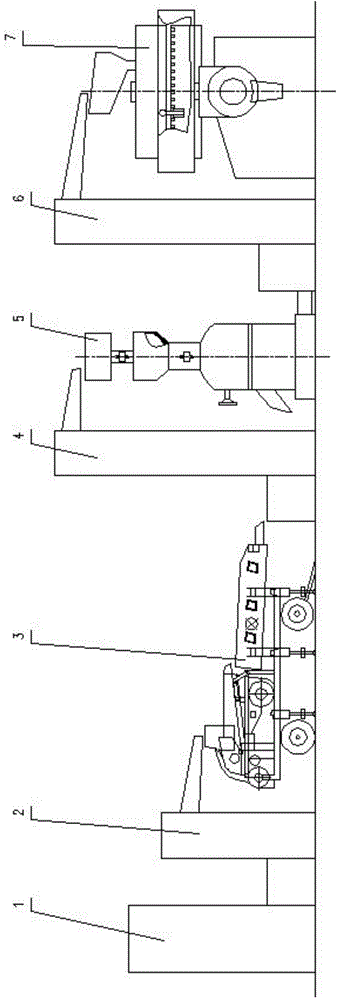

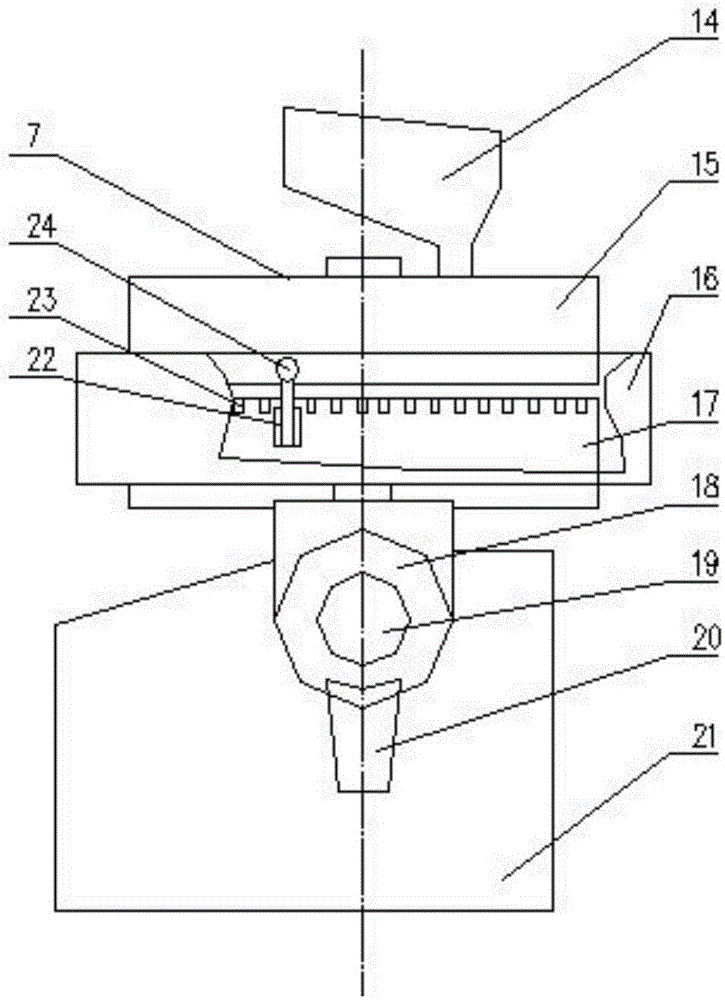

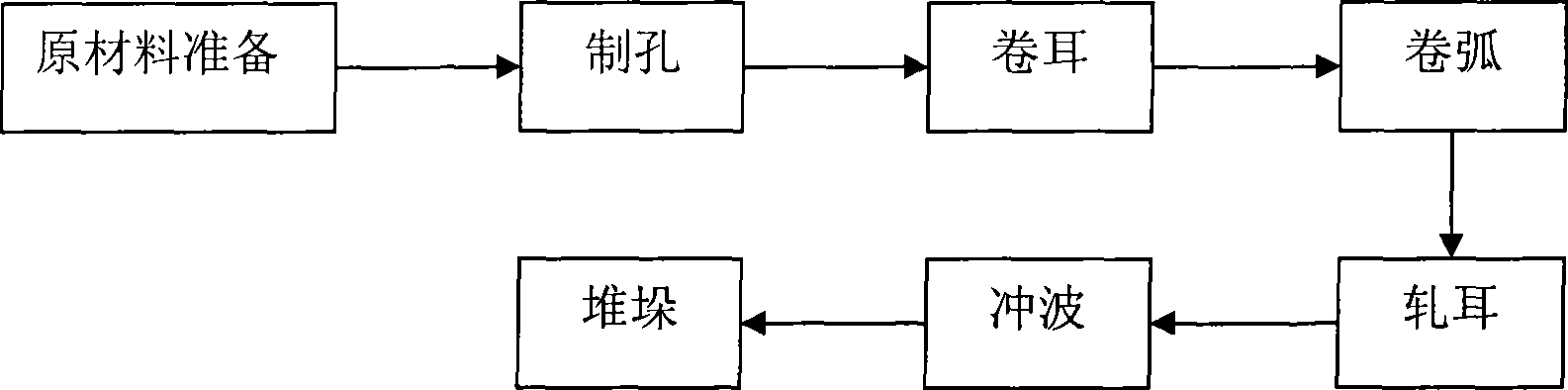

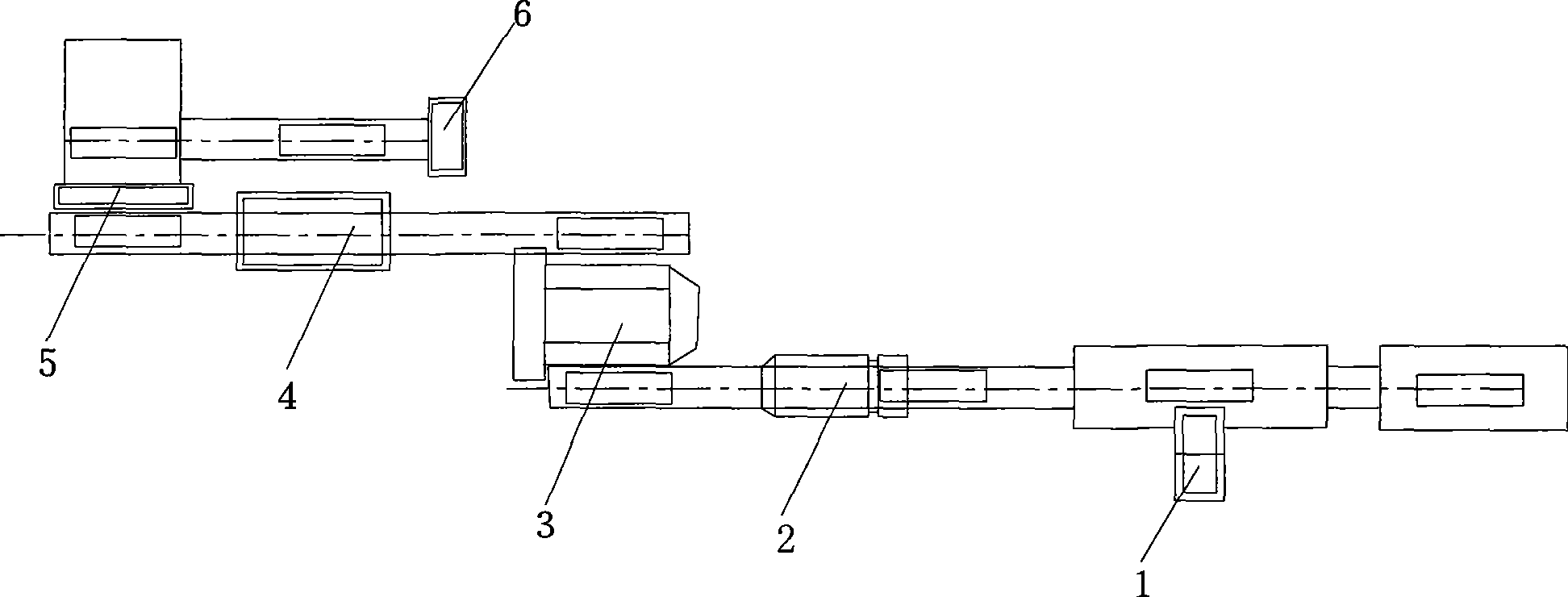

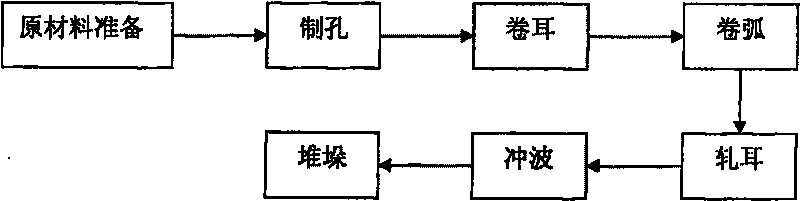

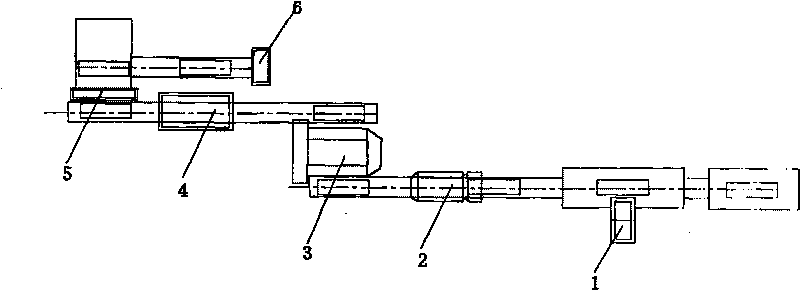

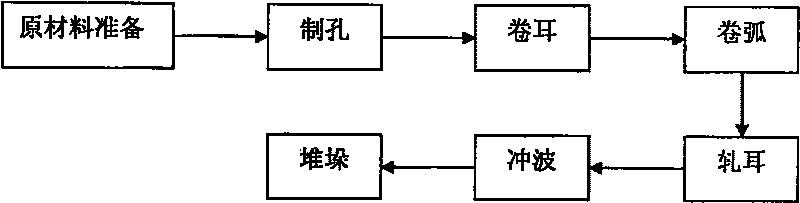

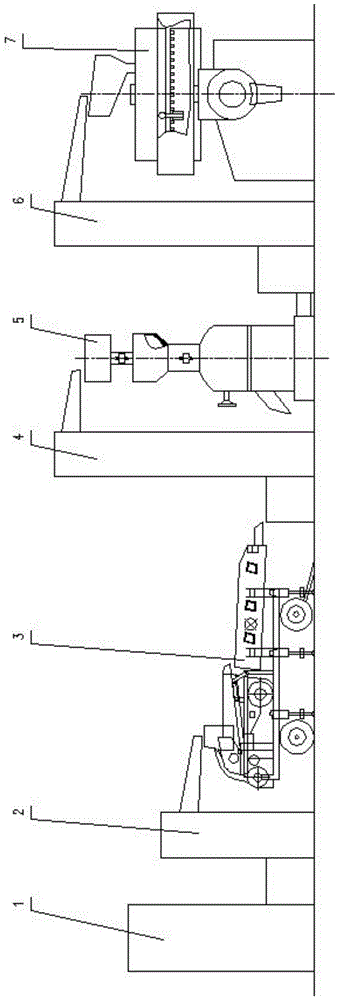

Three-dimensional corrugated steel production technique and special device thereof

The present invention provides a process for producing three-dimensional wave steel plates and special equipment thereof. The producing flow of the process comprises: preparing raw materials, machining holes, reeling lugs, reeling arcs, rolling lugs, punching waves and stacking. The special equipment of the process is formed by sequentially connecting a punching press, a beading machine, a plate reeling machine, a lug rolling press, an overturning mechanism and a wave punching press through a producing and conveying chain, wherein a wave punching protecting mechanism is arranged on the wave punching press. The process adopts PLC programmable control technology on a production line, so as to improve the punching efficiency and precision of holes and waves on the three-dimensional wave steel plates. The visualized screen operation of the process realizes the integrated control of a system; at the same time, through establishing a fault mode, every node in the process of production is monitored, so that the reliability and the intellectualization level of the whole system are improved. At the time of improving production efficiency and finished product quality, manual operation procedures are reduced and labor strength is reduced.

Owner:GUANGZHOU MILITARY AREA AIR FORCE ENG CONSTR BUREAU PLA

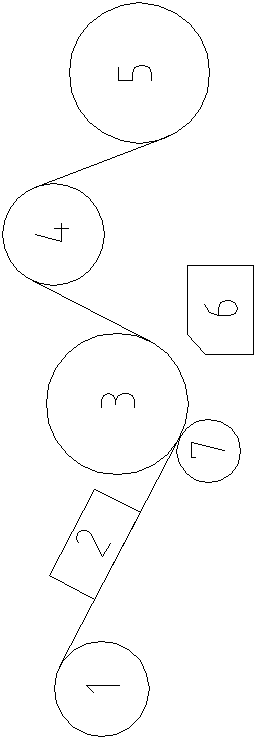

Cold pressing system and technology of cold pressing type micro lenticulation

ActiveCN104228074ALittle flexibilityIncrease production capacityOptical articlesDiffraction gratingsGratingAutomatic control

The invention discloses a cold pressing system of a cold pressing type micro lenticulation. The cold pressing system sequentially comprises a PET membrane base material roller, a coating machine, an optical grating module roller, a transmitting roller and a finished product material receiving roller, wherein a compression roller and a curing lamp box device are arranged below the optical grating mold roller. According to the invention, because the cold pressing system and technology of the cold pressing type micro lenticulation are adopted, the automatic production and automatic control are convenient, the manual operation working procedure is reduced, the product consistency is ensured, and the factor of expansion caused by heat and contraction caused by cold is eliminated, and thus the technology is simple, the data are accurate, the material elasticity is low, the three-dimensional sense is obvious, and the cost is low.

Owner:HENAN SANYANG PHOTONICS

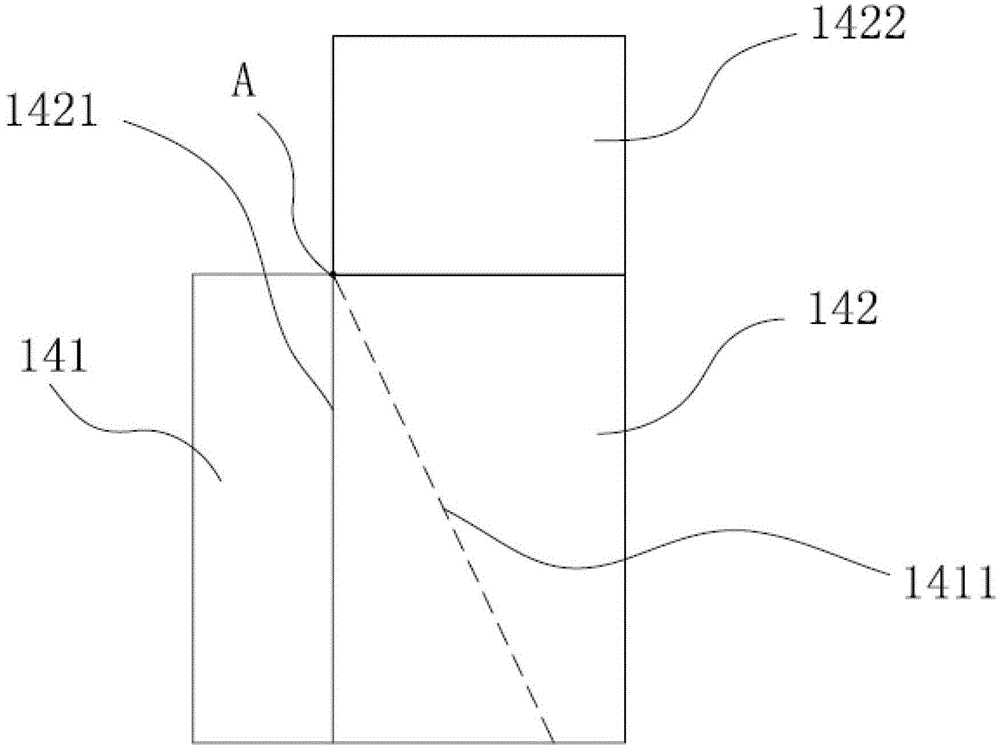

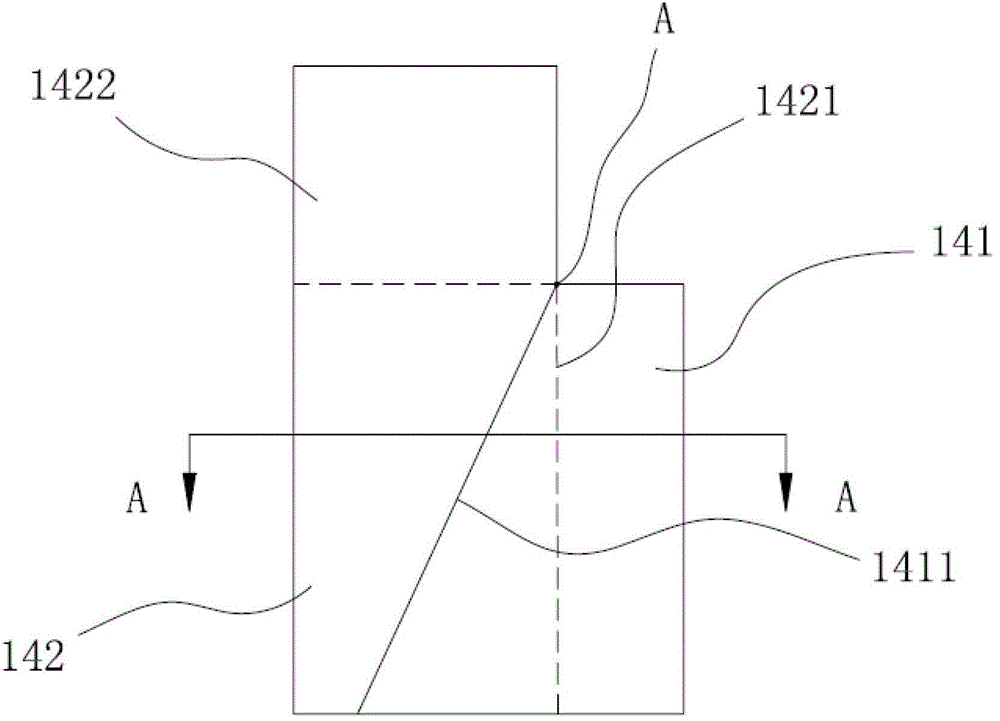

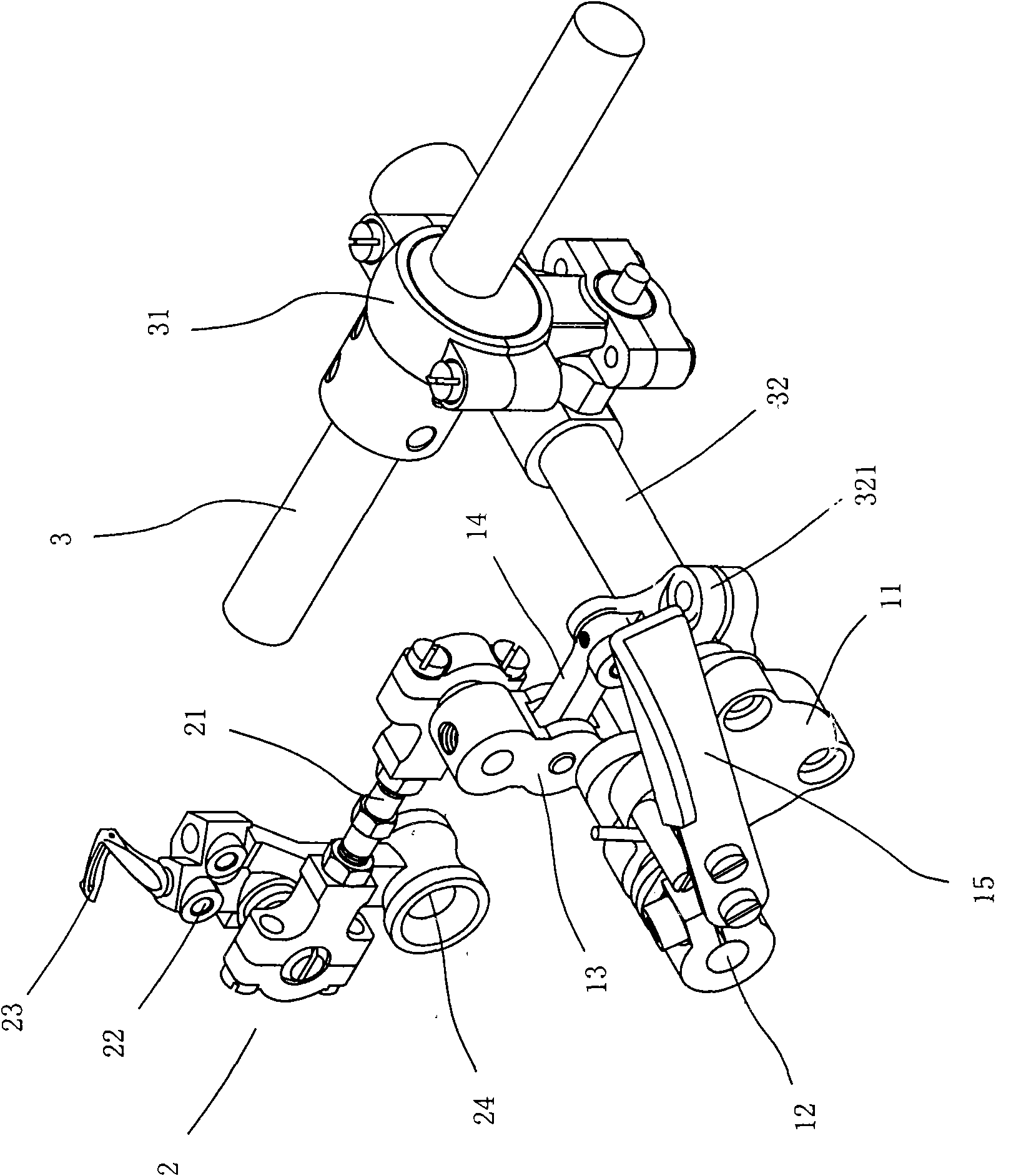

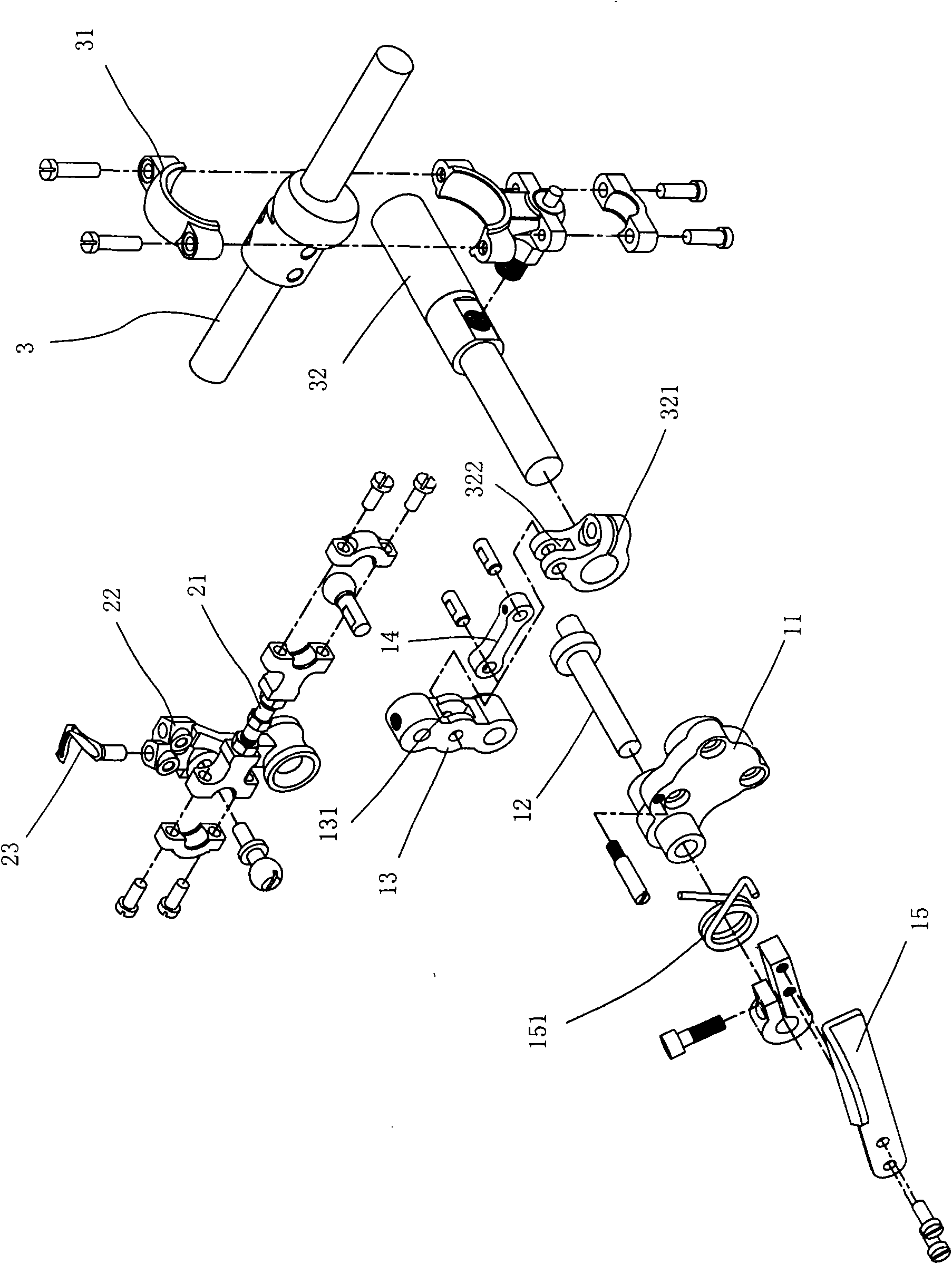

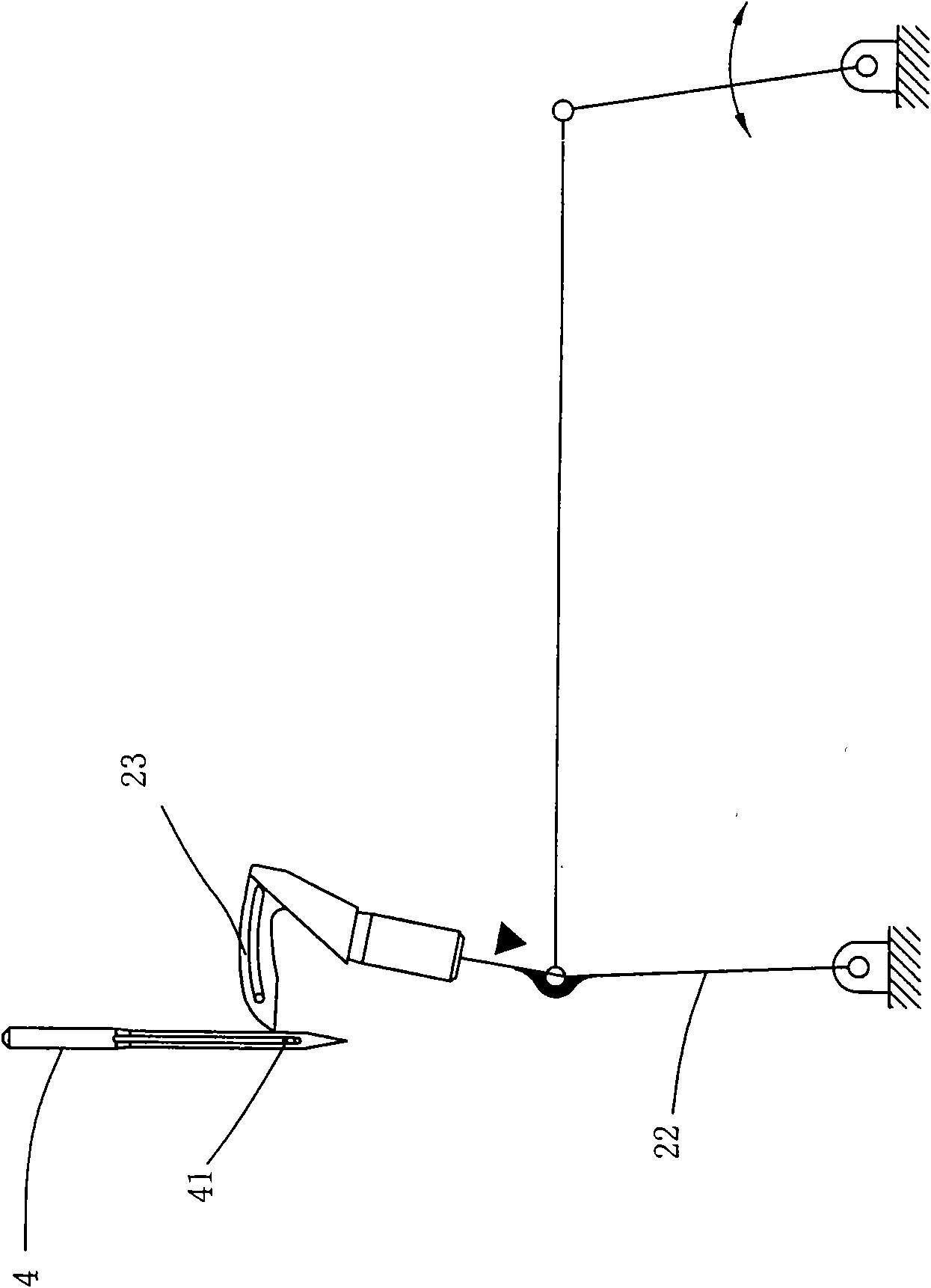

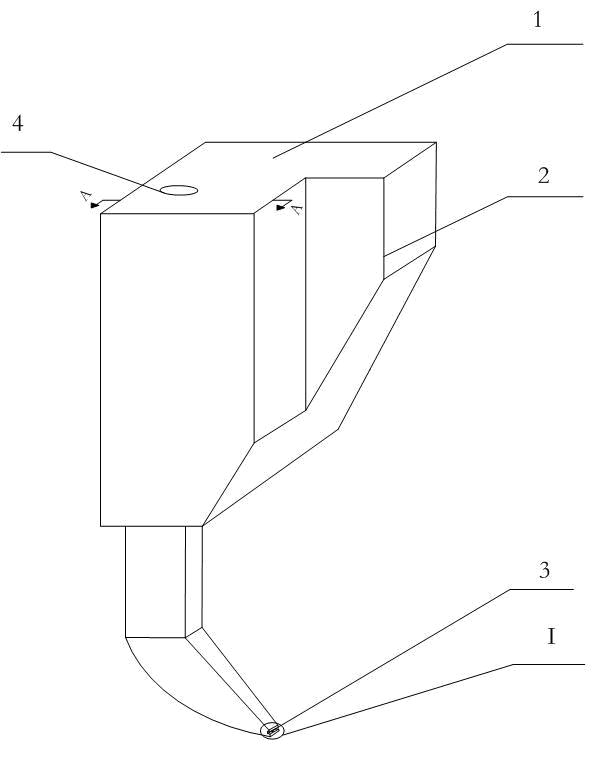

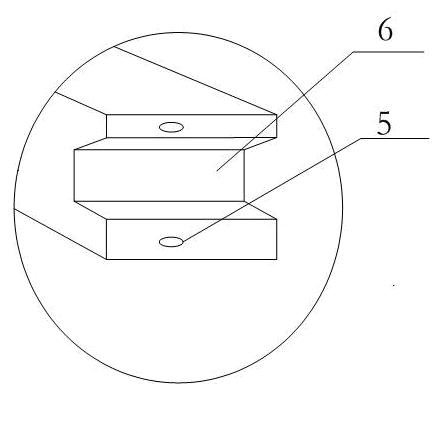

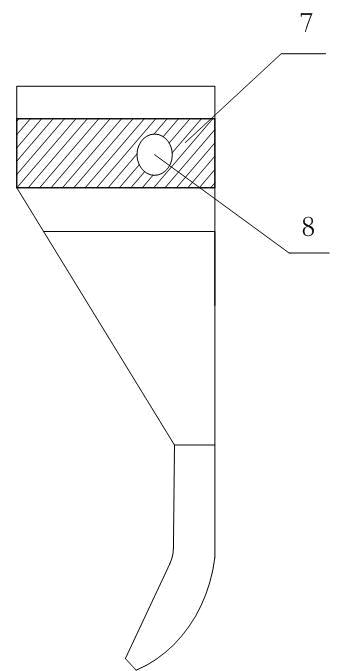

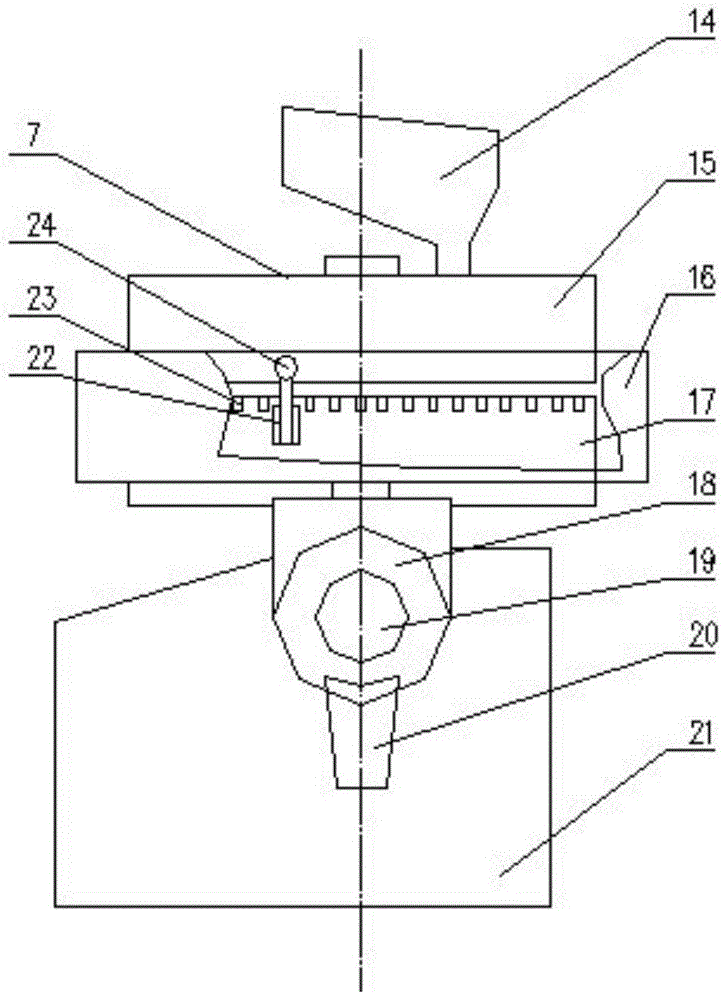

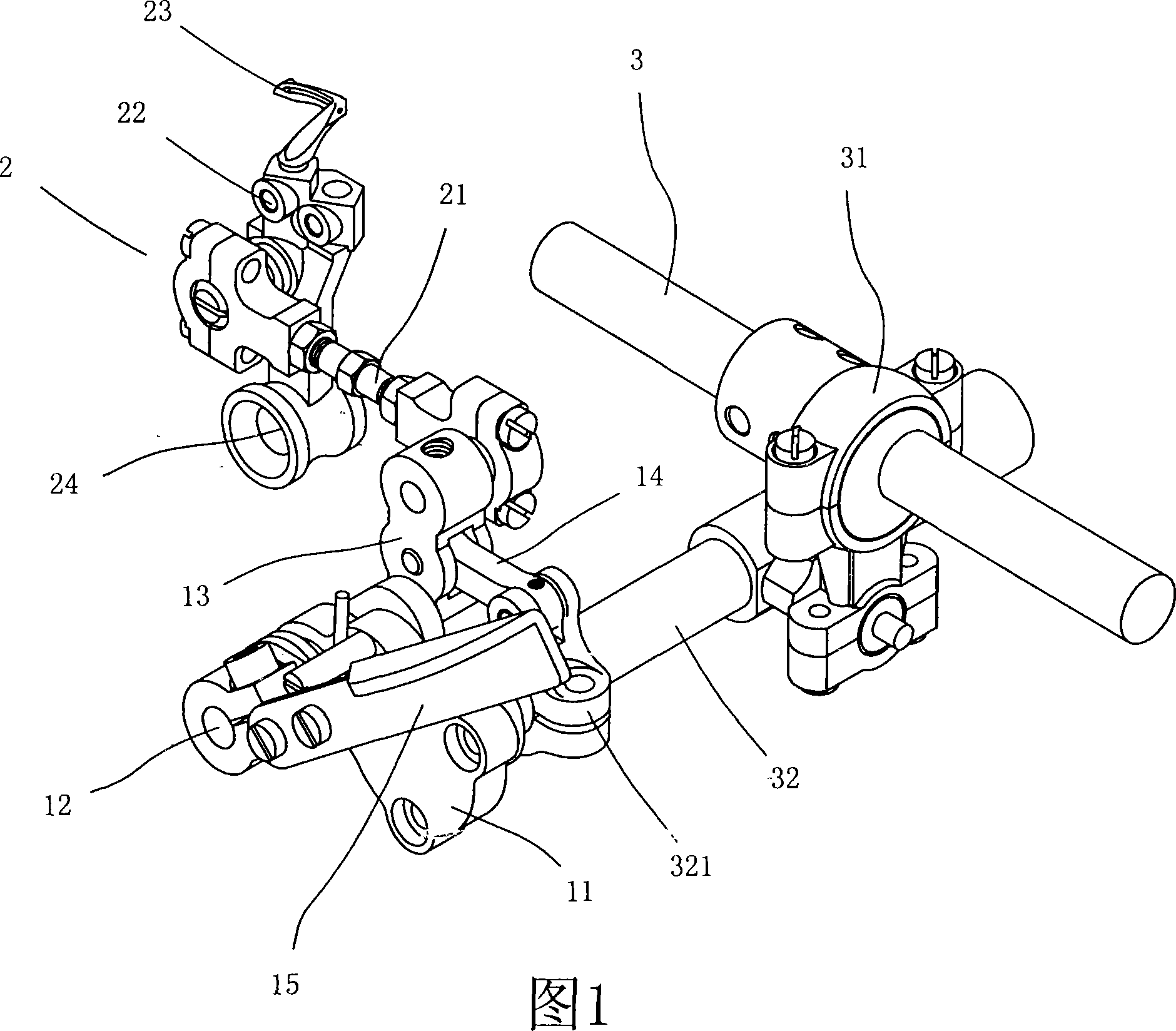

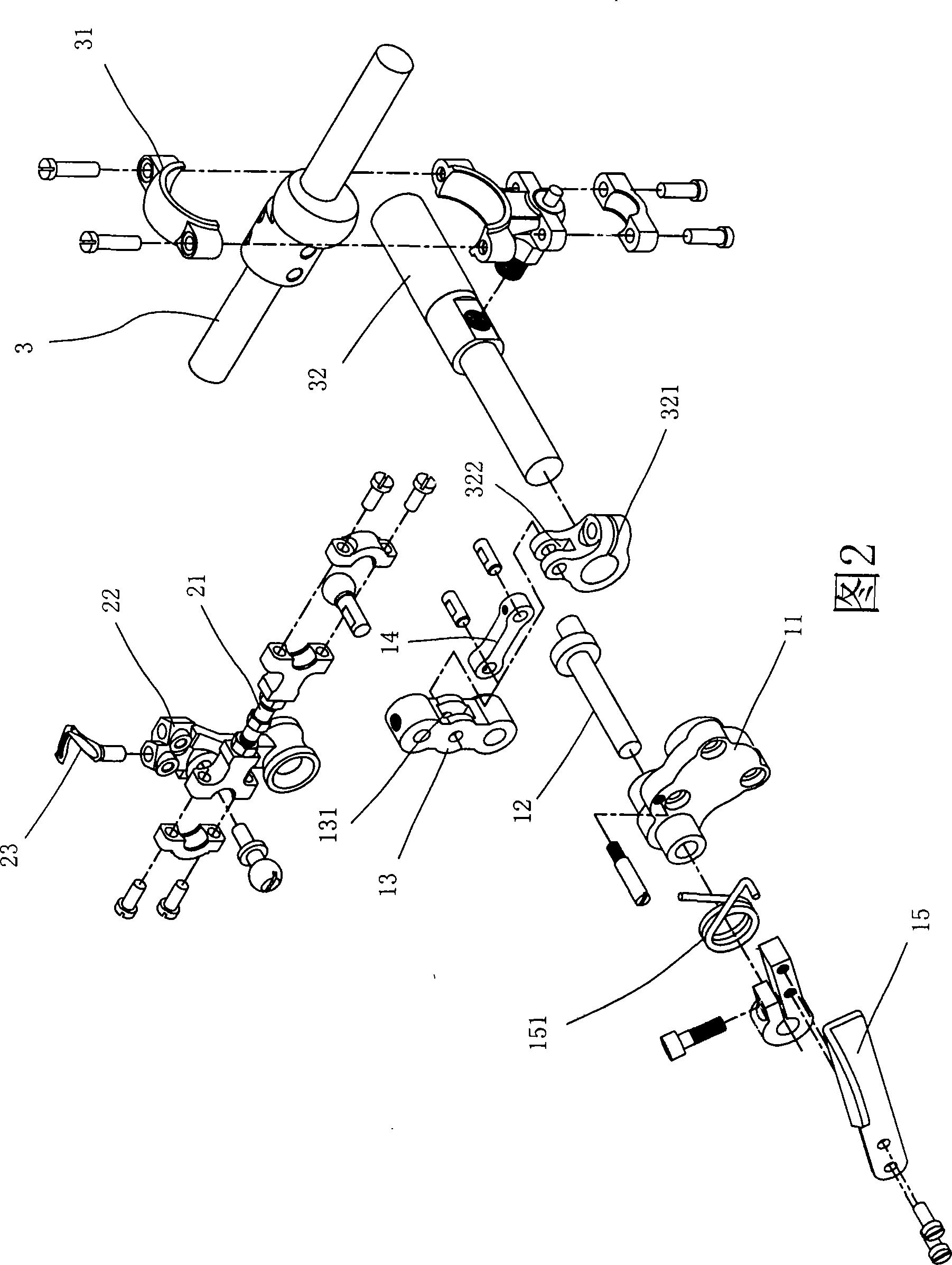

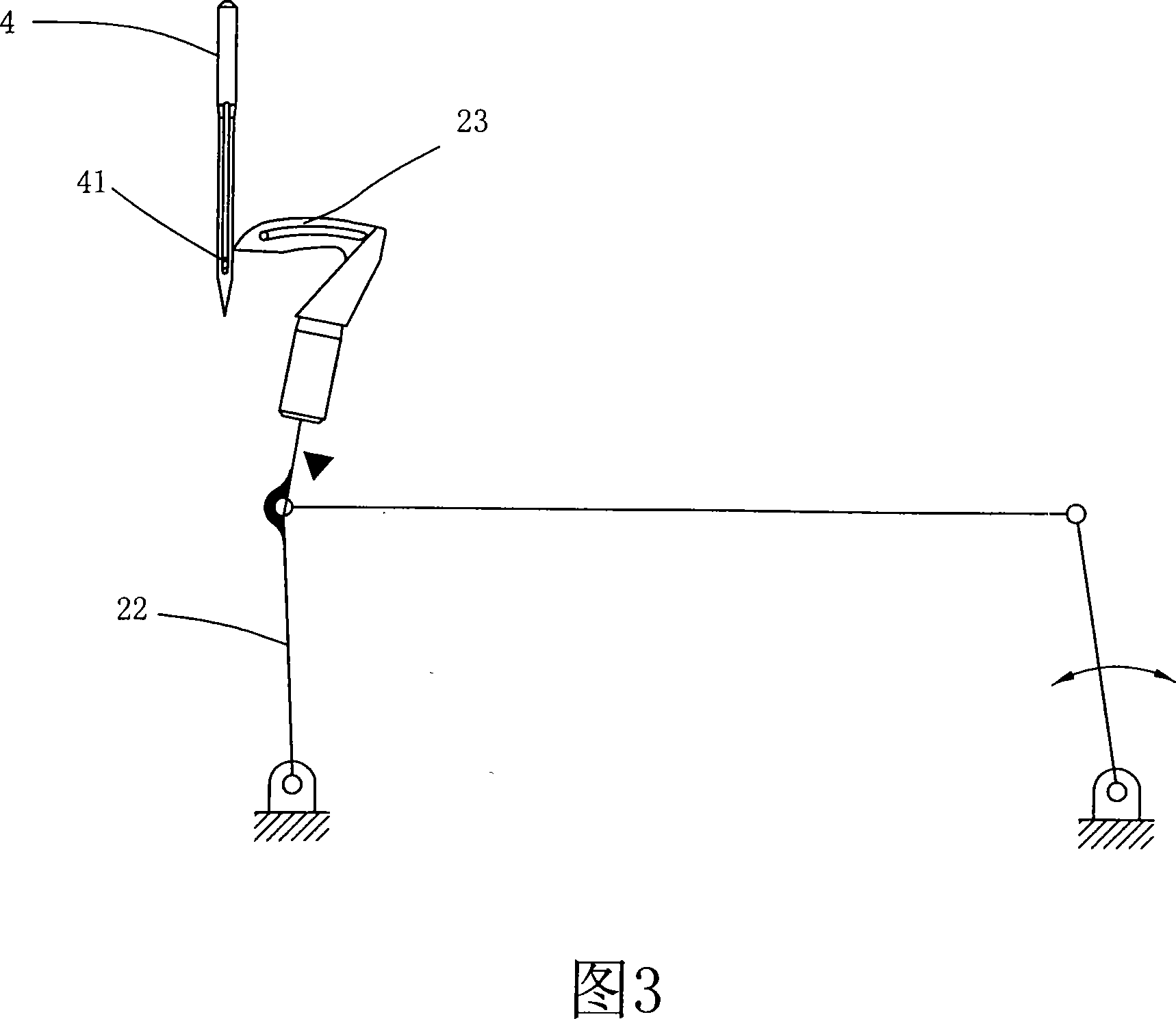

Skipping stitch device of sewing machine

InactiveCN101565882ASkipping effect is stableReduce manual proceduresSewing-machine control devicesLoop takersTransverse axisAutomatic control

The invention relates to a skipping stitch device of a sewing machine, which mainly comprises a fixed seat, an eccentric shaft, a rocker, a connecting rod and a deflecting control rod. The fixed seat is combined with a sewing machine body and used for sleeving the eccentric shaft and a torsional spring; the eccentric shaft is inserted into the fixed seat; the rocker is combined with one end of the eccentric shaft, and the other end of the eccentric shaft is combined with a bearded needle table by a ball-and-socket connecting rod; the connecting rod is arranged between a swinging arm on a cross shaft of the sewing machine and the rocker; and the deflecting control rod is arranged at the other end of the eccentric rod. The skipping stitch device can be provided for an operator to control a connecting mechanism by the deflecting control rod to drive a bearded needle to make micrometric displacement, ensures that the bearded needle cannot hook the needle and lines and easily controls the action of a skipping stitch by controlling the deflecting control rod and other automatic control modes, thereby sewing and wrapping operations can be conveniently achieved, the procedures and the time of manual operation can be saved, and operation efficient workers can be increased.

Owner:CHEESIANG SEWING MACHINE S H

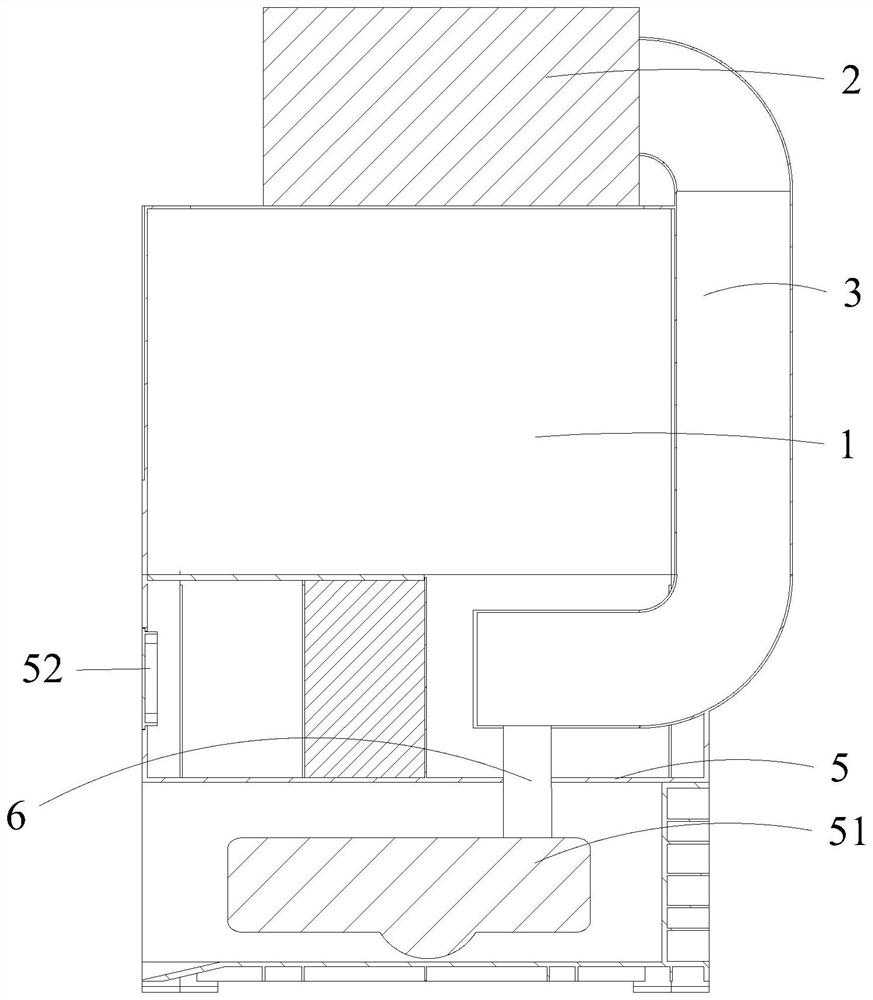

Glue-extruding device for autosizing flanging machine

The invention discloses a glue-extruding device for an autosizing flanging machine, comprising a main body. The main body is provided with a connecting part, a glue-injecting hole, a glue-extruding face and a glue passageway, wherein the connecting part is connected with the autosizing flanging machine; the glue passageway is communicated with the glue-injecting hole and the glue-extruding face; the glue-extruding face is provided with a groove formed by indent structures; and the two sides of the groove are respectively provided with a glue-spraying hole. In the invention, the two faces of a reinforcing band can be simultaneously sized after using double-hole sizing, so that the 4mm-5mm of reinforcing band can be flanged together when in use. Thus, the labor cost during the process of manufacturing shoes is saved, and the stable product quality can be ensured, and the flanging is more smooth and beautiful.

Owner:CHENGDU CAMEIDO SHOES

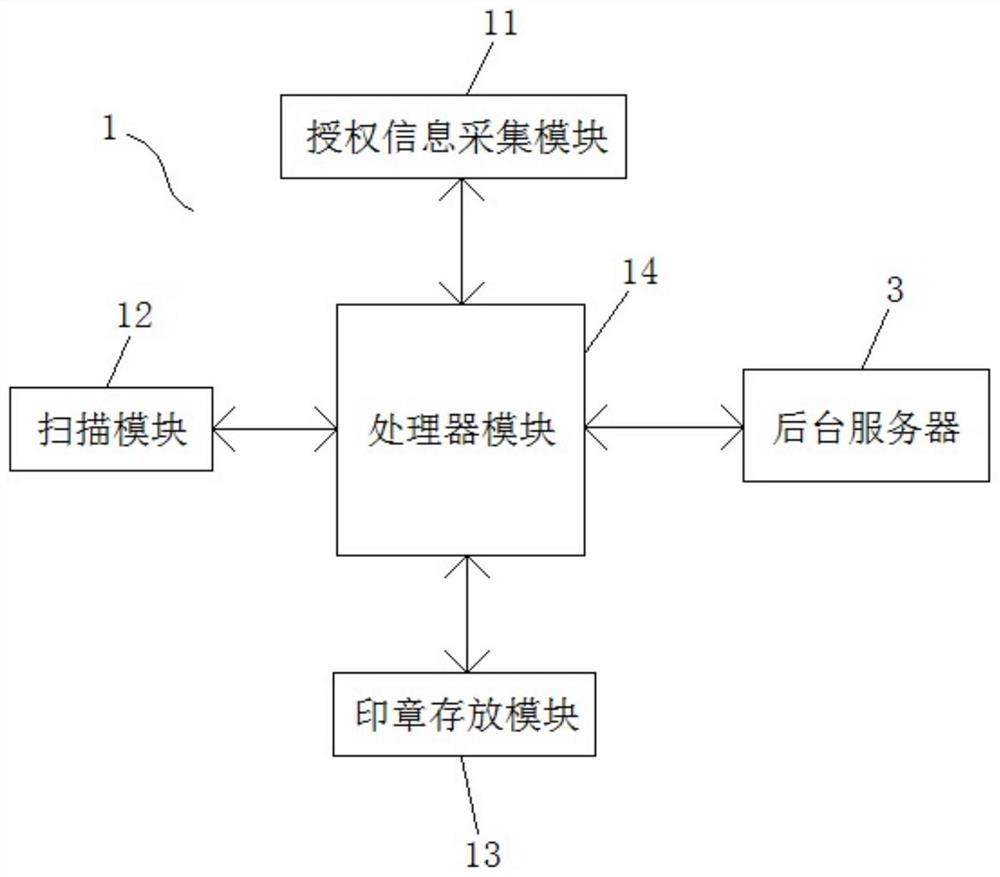

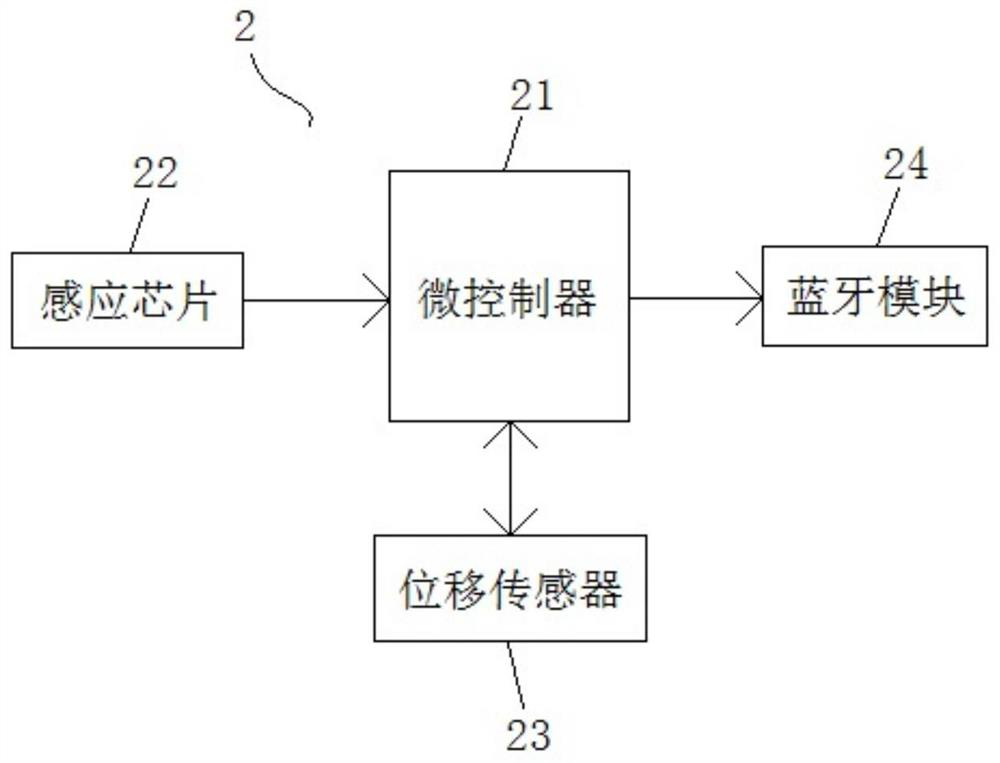

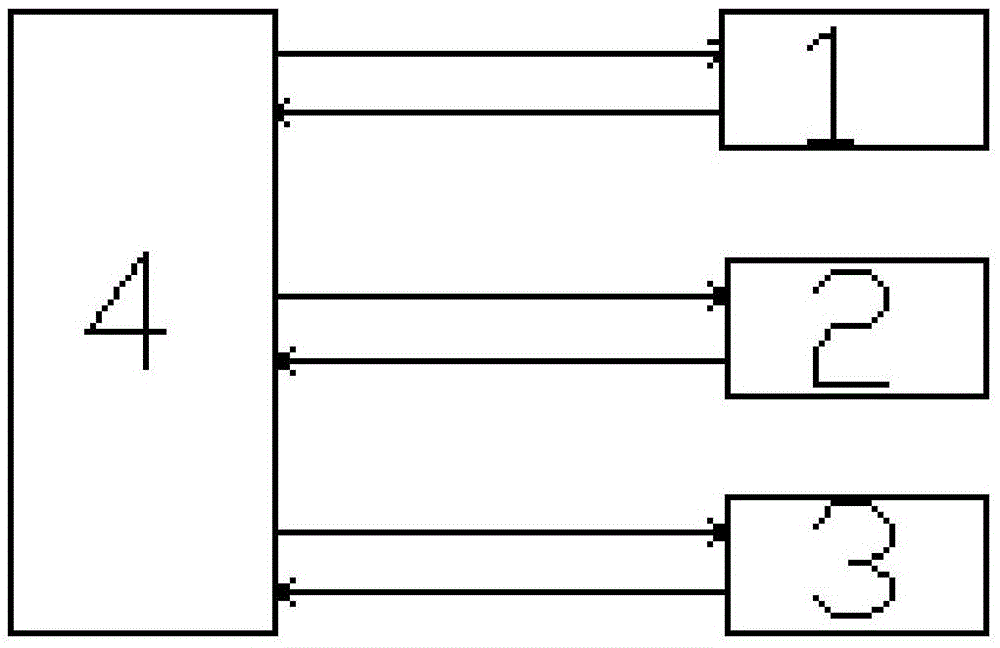

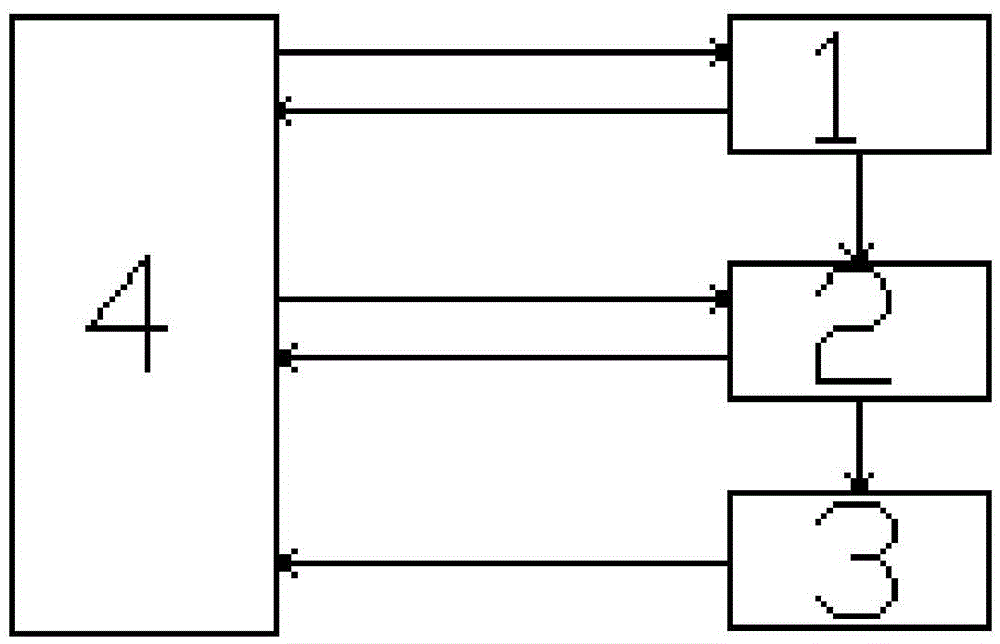

Seal management system for entity seal

PendingCN111951442AImprove securityConvenient queryIndividual entry/exit registersBurglar alarm by hand-portable articles removalSoftware engineeringAuthorization

The invention provides a seal management system for an entity seal. The seal management system comprises a seal storage terminal, an intelligent seal and a background server; the seal storage terminalcomprises an authorization information acquisition module, a scanning module, a seal storage module and a processor module; the authorization information acquisition module is used for acquiring identity information of a seal user, the scanning module is used for acquiring image information of a stamped file before stamping and image information of the stamped file after stamping, the seal storage module is used for storing and locking an intelligent seal, and the processor module is in communication connection with the background server. Therefore, the identity information of the seal user and the image information before and after the seal of the sealed file can be recorded. Stamping operation is achieved on the stamp storage terminal, the manual procedure of examination and approval before stamping is reduced, the stamp storage module can unlock the intelligent stamp only after identity information of a stamp user is successfully verified, and the use safety of the stamp is improved.

Owner:QUANZHOU SHIKE ALARM SYST ELECTRONIC CO LTD

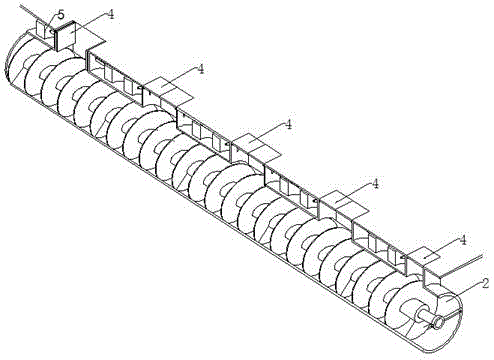

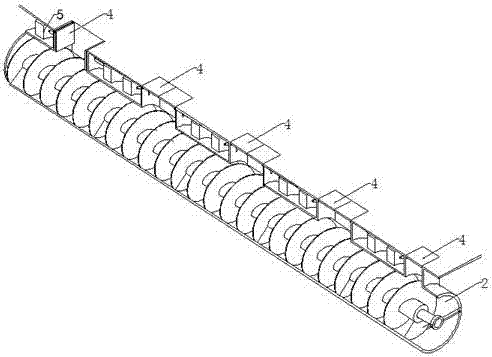

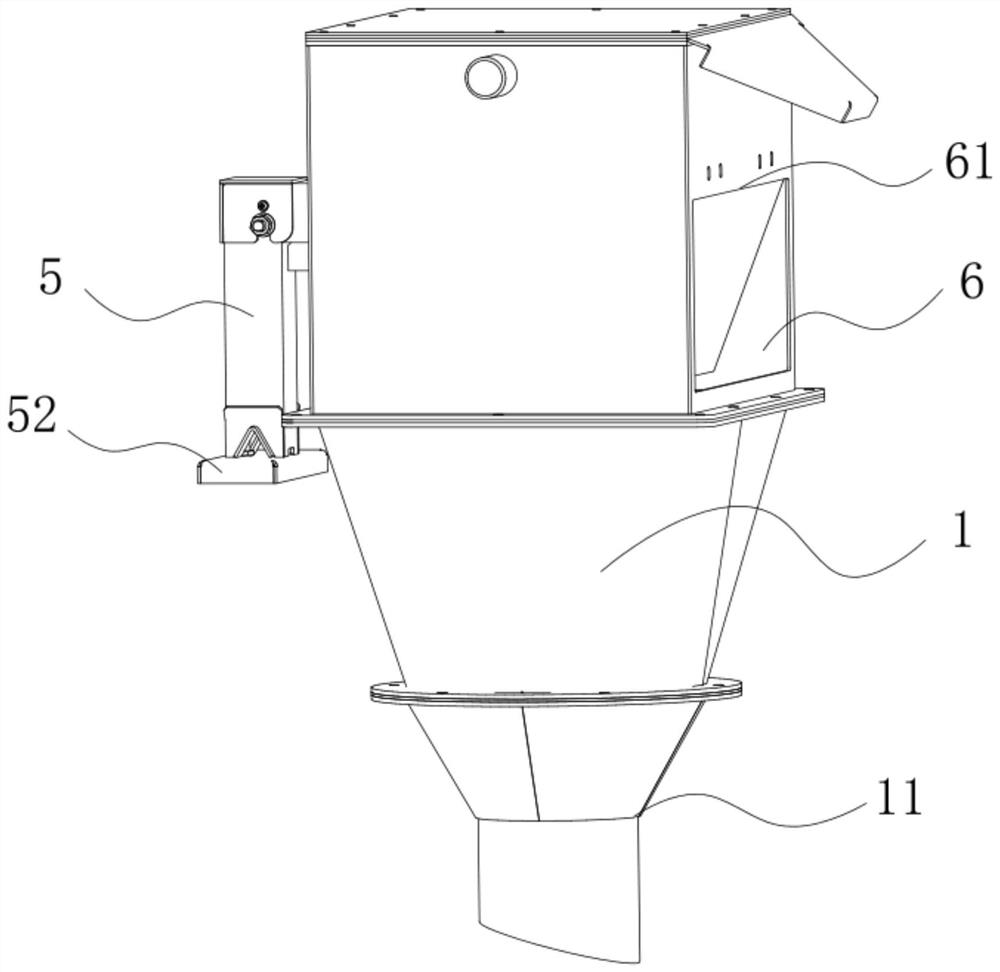

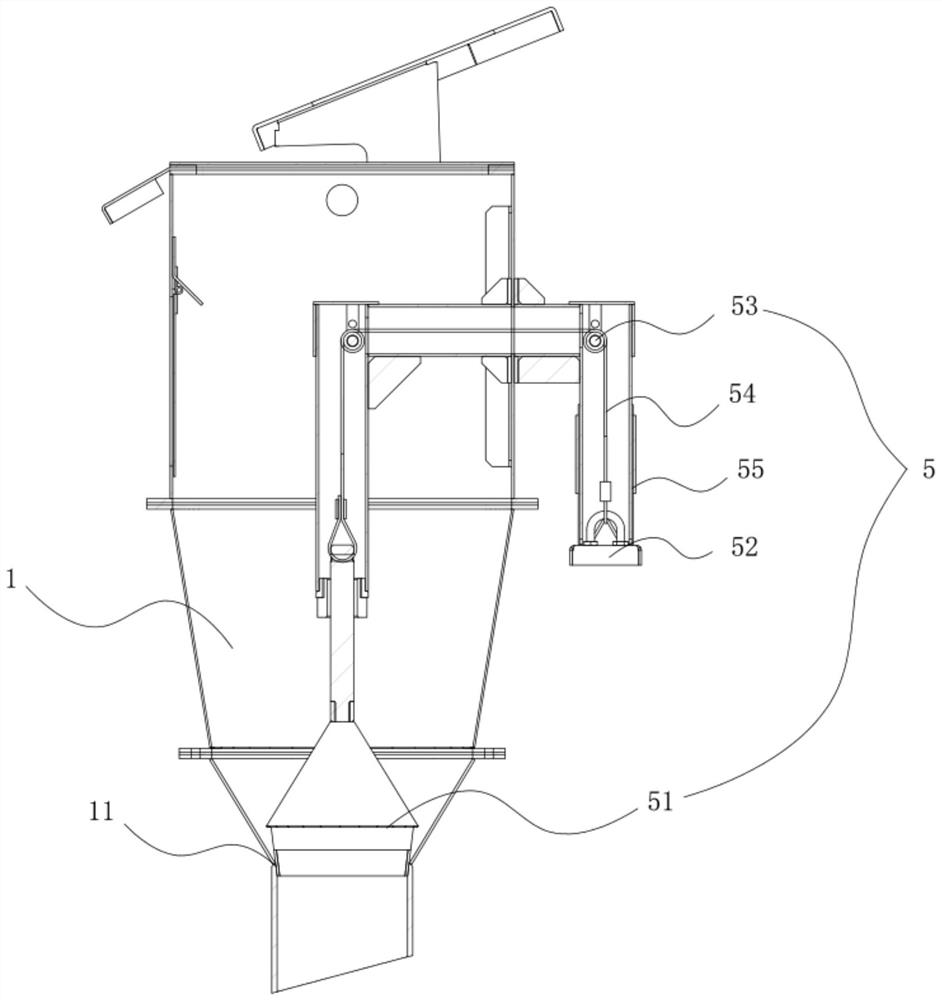

Auger conveying mechanism for dust or particle material storage and transportation container

The invention discloses an auger conveying mechanism for a dust or particle material storage and transportation container. The auger conveying mechanism for the dust or particle material storage and transportation container comprises a conveying groove formed in the bottom of the storage and transportation container, an auger assembly arranged in the conveying groove, and a strip-shaped groove or a plurality of communication holes, wherein the storage and transportation container and the conveying groove are communicated through the stripe-shaped groove or the communication holes, and the communication holes are formed in rows. The length direction of the strip-shaped groove or the arrangement direction of the communication holes is consistent with the conveying direction of the auger assembly. The strip-shaped groove or each communication hole is provided with at least one cover plate. The strip-shaped groove or the communication holes can be closed or opened through the cover plates under the control of control assemblies. In this way, in an actual operation process, the cover plate close to a discharge outlet can be closed, and the cover plate away from the discharge outlet can be opened, so that the situation that when materials at the end away from the discharge outlet are discharged firstly, materials at the end close to the discharge outlet apply pressure to the auger assembly through the strip-shaped groove or the communication holes, and accordingly certain resistance is caused to the movement of the auger assembly is avoided; the conveying efficiency of the auger assembly is improved, and energy resources are saved.

Owner:NENGCHENG GRP

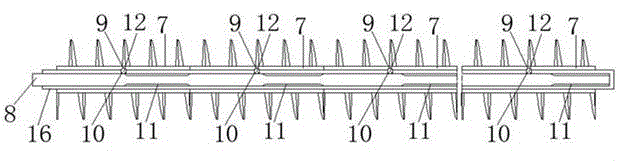

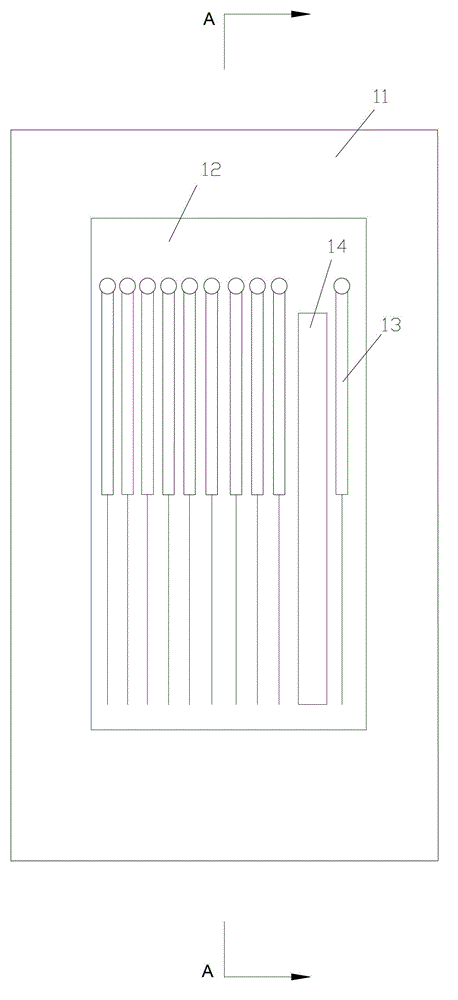

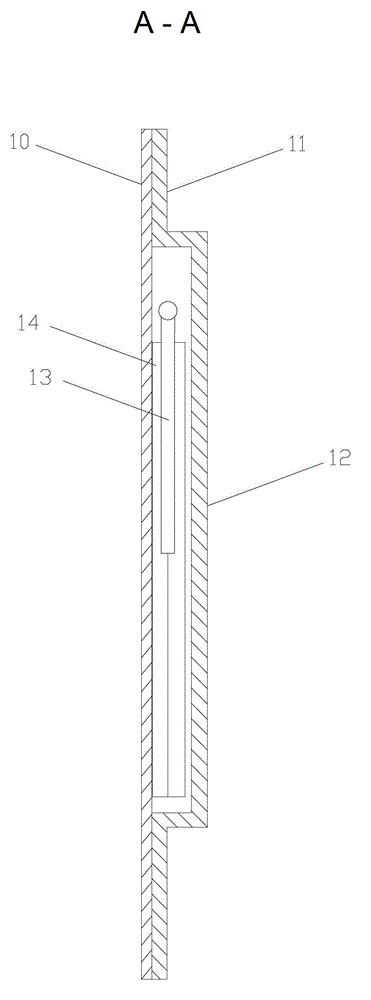

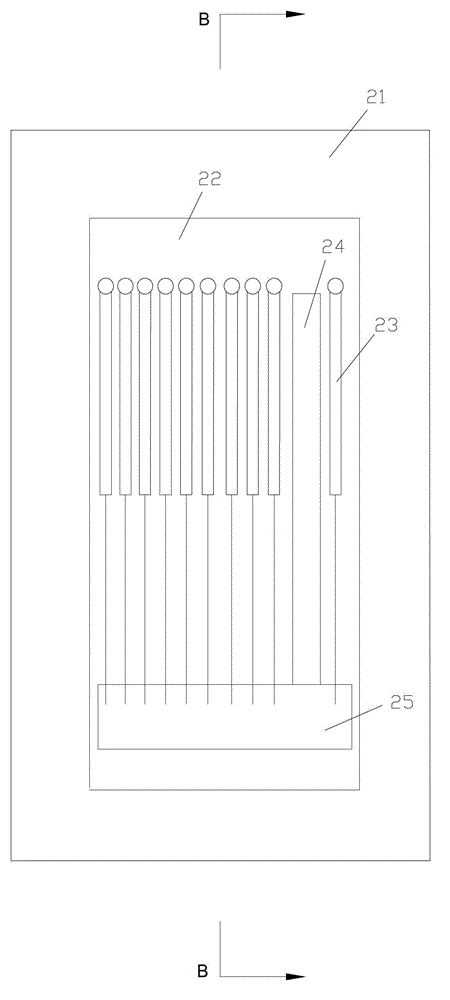

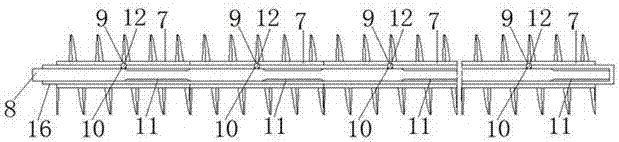

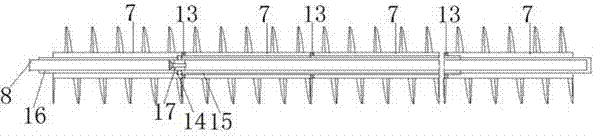

Acupuncture needle packaging body

The invention provides an acupuncture needle packaging body which comprises a bottom plate and a top plate. A needle storage space for placing acupuncture needles is arranged in the middle of the top plate. The bottom plate and the top plate are bonded in rims. The needle storage space is further internally provided with a foam block for protecting the needle points. The acupuncture needle packaging body is characterized in that one end of the needle storage space is provided with a positioning space for fixing the foam block. The positioning space is wider that the part of the needle storage space where the acupuncture needles are arranged. The foam block is matched with the positioning space in shape. Compared with the prior art, according to the acupuncture needle packaging body provided by the invention, as the needle storage space is provided with the positioning space for fixing the foam block, and the positioning space is wider than the needle storage space, the points of the acupuncture needles are protected by the foam block all the way, so that the acupuncture needles are better protected.

Owner:陈悦婷

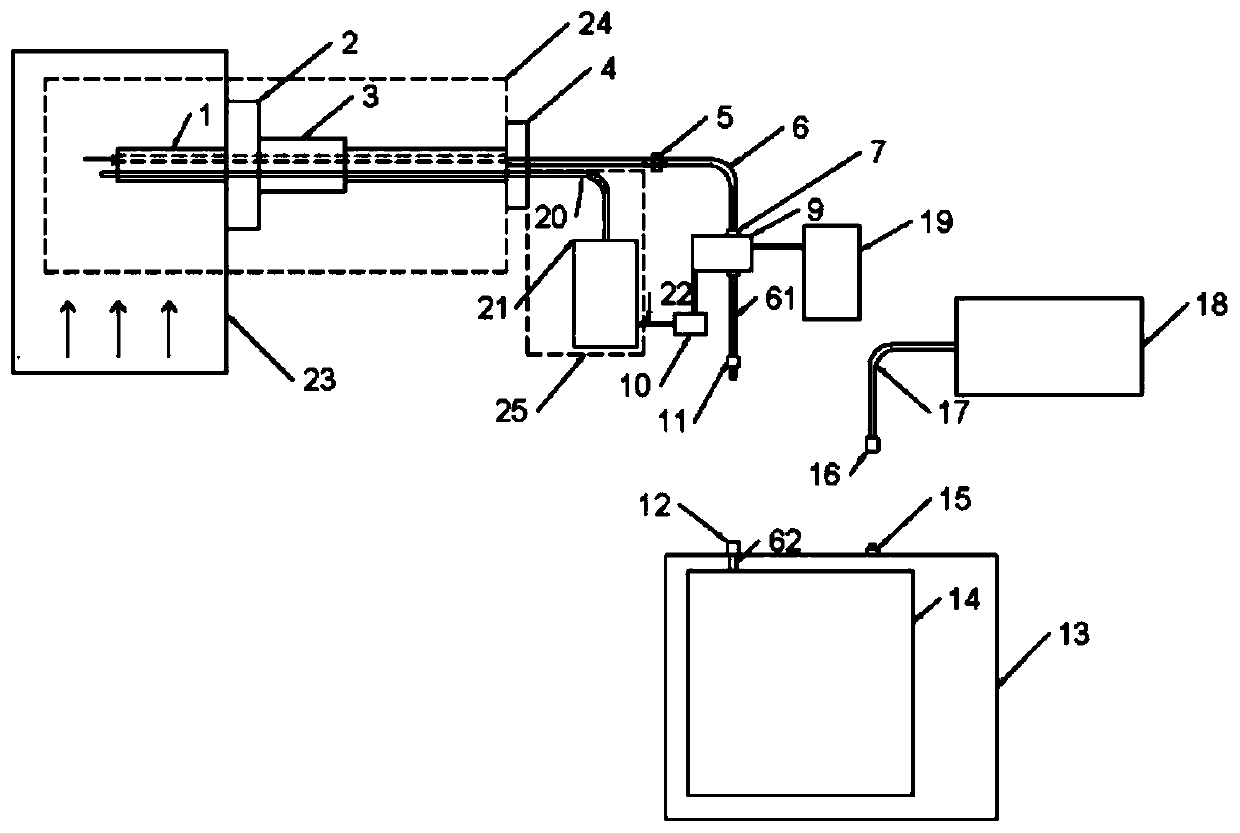

Sampling system and method for fixed gas emission source, and application thereof

PendingCN110763526AAvoiding Concentration UncertaintyReduce manual proceduresVolume measurement apparatus/methodsWithdrawing sample devicesInformation processingProcess engineering

The invention provides a sampling system and method for a fixed gas emission source. The sampling system comprises a sampling device, a flow sensing device, an information calculation device, a flow control processing device and a flow integrating device, wherein the sampling device is configured to receive a gas from a fixed gas emission source; the flow sensing device is configured to monitor, read and store the wind speed value of the gas; the information calculation device is configured to obtain information processing data according to the wind speed value; the flow control processing device is configured to convert the information processing data into an electromagnetic signal and transmit the electromagnetic signal to the flow integrating device; and the flow integrating device is configured to obtain sampling data according to the electromagnetic signal. According to the sampling system and method for the fixed gas emission source, the total emission amount of gas can be accurately estimated, digital monitoring of the sampling process is achieved, and information records are obtained.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

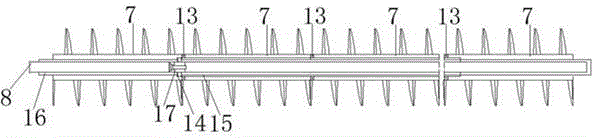

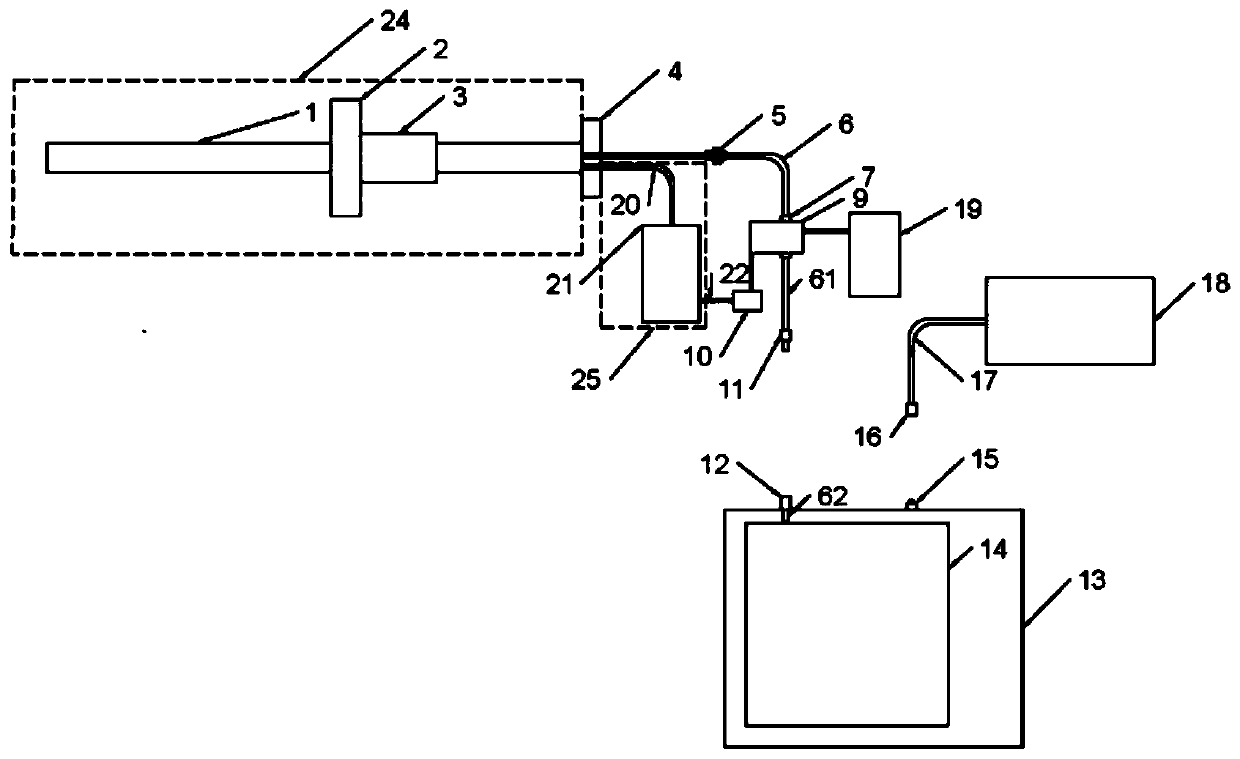

Power-cut work safety protection system for railway overhead line system

ActiveCN105620311AEnsure grounding reliabilityReduce manual proceduresPower supply linesVideo monitoringHigh pressure

The invention provides a power-cut work safety protection system for a railway overhead line system.The power-cut work safety protection system for the railway overhead line system comprises grounded lines, high-voltage electricity testing equipment, an electric mechanism, a grounding detection mechanism, first video monitoring equipment, second video monitoring equipment and remote control equipment.The power-cut work safety protection system for the railway overhead line system is safe, economical and rapid, and can be applied to substations, switching stations and section posts of railway lines and special lines with frequent work of electrified railway loading and unlocking trucks; the grounded lines of the overhead line system can be switched on or switched off under remote control, so that manual operation procedures are reduced, and safety measure layout time is shortened; meanwhile, grounding reliability of grounded circuits is ensured through corresponding detection equipment, so that work safety is greatly improved.

Owner:北京诚骋成科技发展有限公司

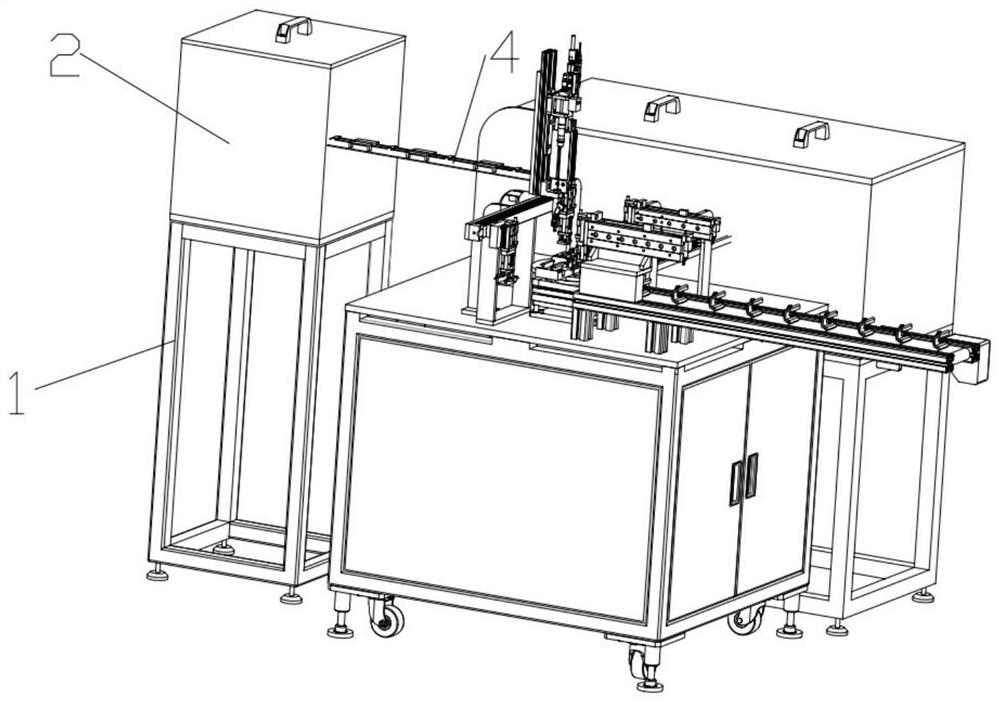

Automatic bowl plug feeding device

InactiveCN105058027AReduce manual proceduresImprove work efficiencyMetal working apparatusSpray nozzleEngineering

The invention provides an automatic bowl plug feeding device. The automatic bowl plug feeding device comprises a rack, a feeding track, a bowl plug conveying cylinder, a rotary cylinder, a gluing device, a gluing table and a long-distance conveying cylinder. The bowl plug conveying cylinder is located on the feeding track. One end of the feeding track is connected to the rack. The rotary cylinder is fixed to the rack and arranged at an outlet, in the rack, of the feeding track. A mechanical grip is arranged at one end of the rotary cylinder and comprises two grabbing fingers which can be opened and closed. The gluing table is located beside the rotary cylinder. The gluing device is located above the gluing table through a gluing frame and provided with a glue spraying nozzle. The gluing frame is located on the rack. The long-distance conveying cylinder is located below the gluing table. A servo motor which makes the gluing table make horizontal circumferential rotation is arranged below the gluing table. According to the structure, automatic bowl plug feeding and gluing are achieved, production cost is reduced, and production efficiency is improved.

Owner:KETENG IND PANYU CITY

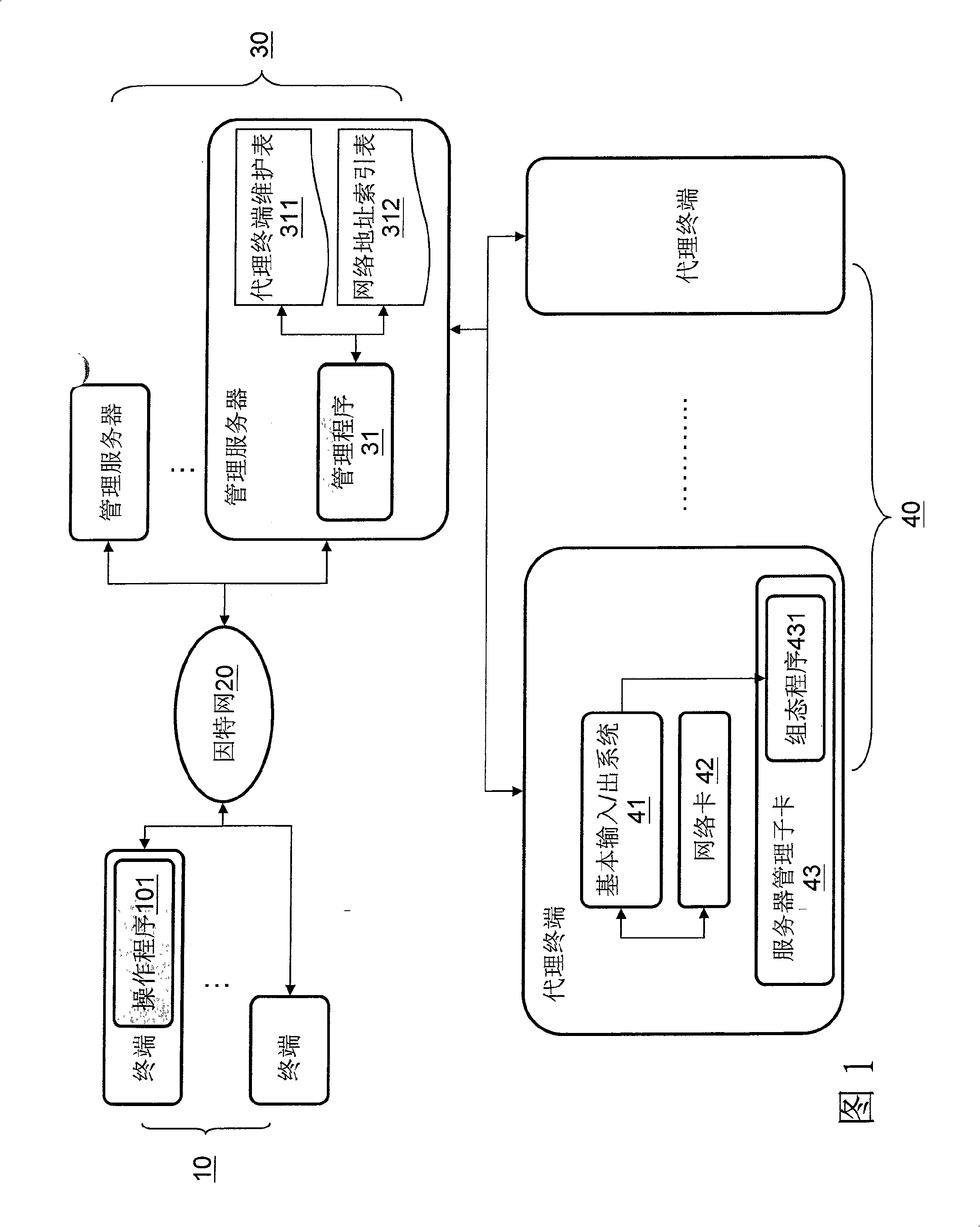

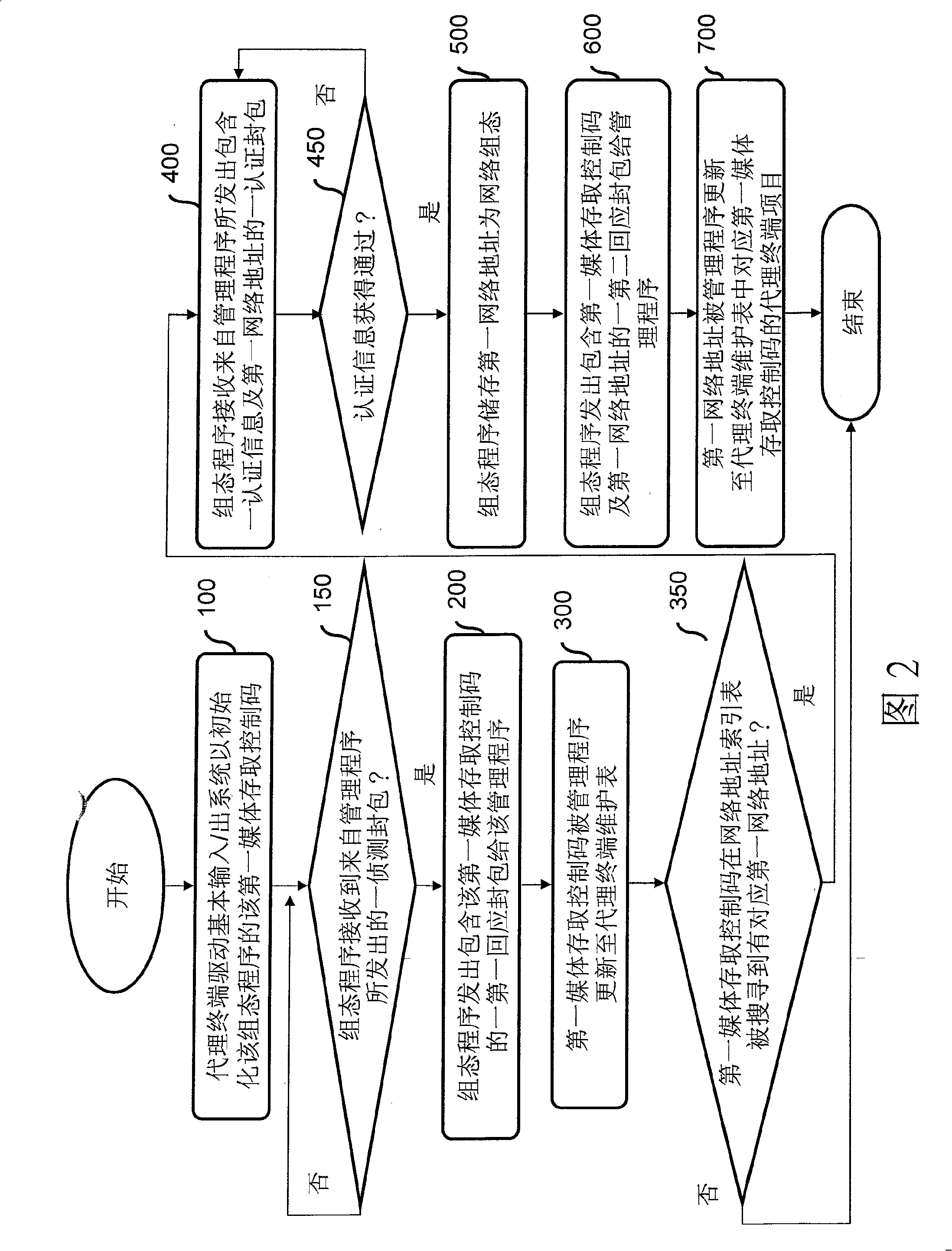

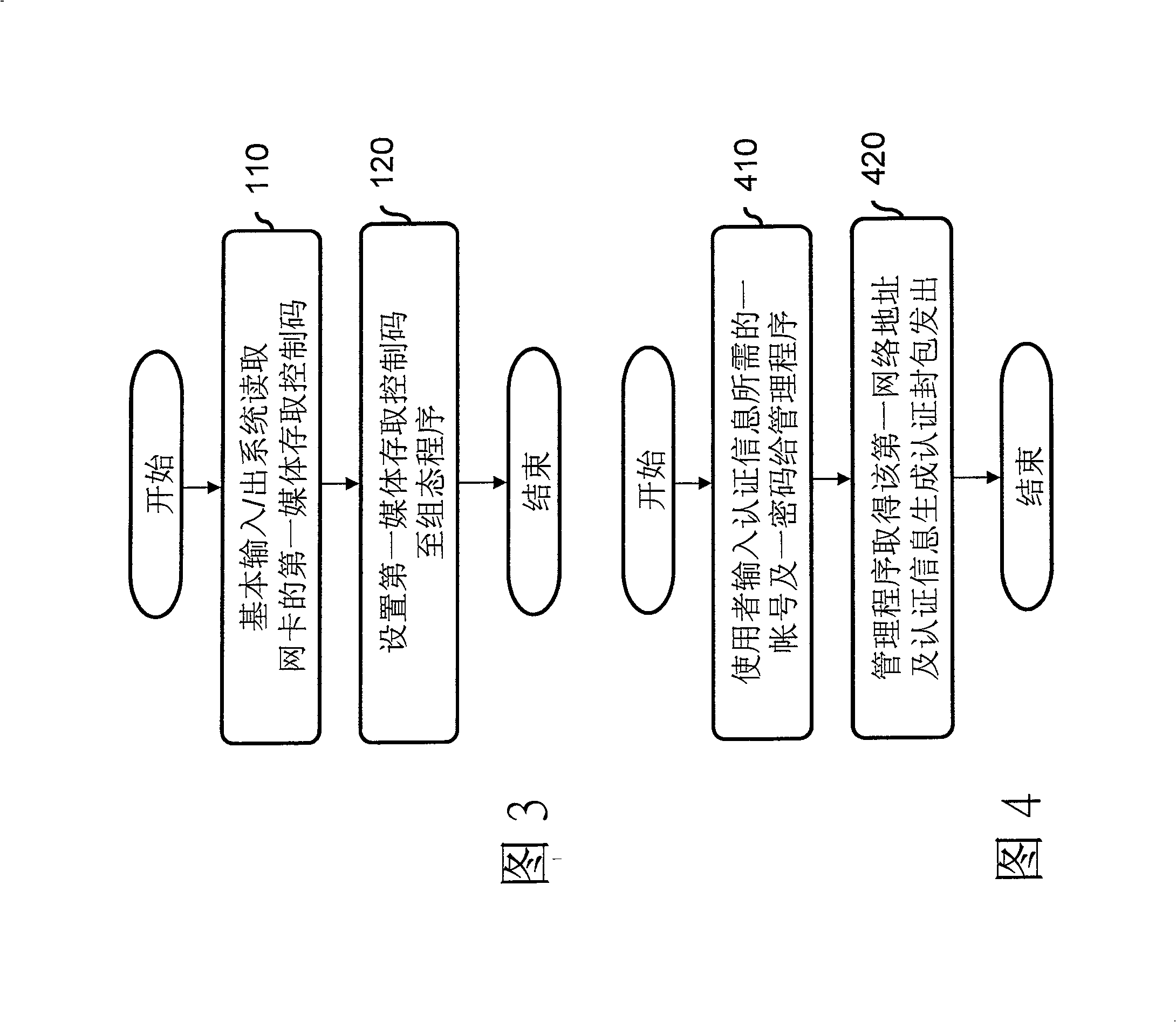

Computer executable network configuration remote dynamic setting method and its system

InactiveCN100479381CEasy to set upImprove setup efficiencyData switching networksNetwork addressingNetwork address

A method for dynamically and remotely setting network configuration being able to be executed by computer includes obtaining media access control code by management sub-card of server on agent terminal when agent terminal is started up and then requesting a corresponding network address from remote management server for finalizing dynamic-setting of network configuration on agent terminal.

Owner:HUANDA COMPUTER (SHANGHAI) CO LTD

Auger conveying mechanism for dust or granular material storage and transportation container

ActiveCN105417204BSave energyEasy to operatePackagingLoading/unloadingEngineeringMechanical engineering

The auger conveying mechanism of the dust or granular material storage and transportation container disclosed by the present invention comprises a conveying trough arranged at the bottom of the storage and transportation container, an auger assembly arranged in the conveying trough, and a mechanism connecting the storage and transportation container with the conveying trough A strip-shaped slot or several communicating holes arranged in a row, wherein the length direction of the strip-shaped slot or the arrangement direction of the communicating holes is consistent with the transport direction of the auger assembly, and at least one cover plate is provided on the strip-shaped slot or each communicating hole , the cover plate can close or open the bar-shaped groove or communication hole under the action of the control component. In this way, in the actual operation process, the cover plate close to the discharge port can be closed, and the cover plate at the end far away from the discharge port can be opened, so as to avoid the material close to the discharge port in the process of first sending out the material at the end far away from the discharge port. The material exerts pressure on the auger assembly through the strip groove or the communication hole, thereby generating certain resistance to the movement of the auger assembly, so as to improve the conveying efficiency of the auger assembly and save energy.

Owner:NENGCHENG GRP

Paper handkerchief folding machining device

ActiveCN103332525BIncrease productivityHigh speedFolding thin materialsArticle deliveryPulp and paper industryFast speed

Owner:中顺洁柔(云浮)纸业有限公司

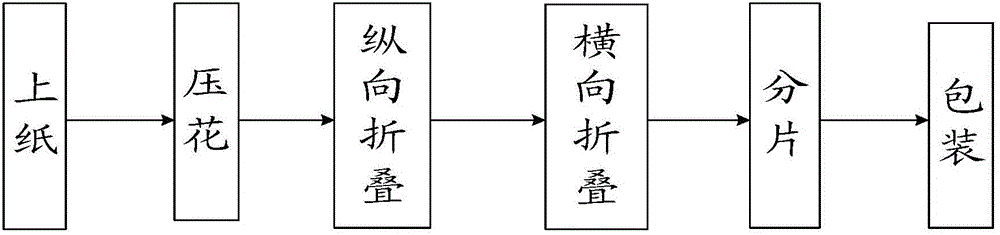

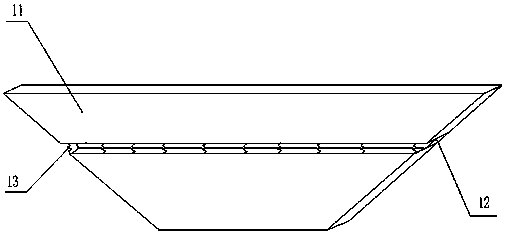

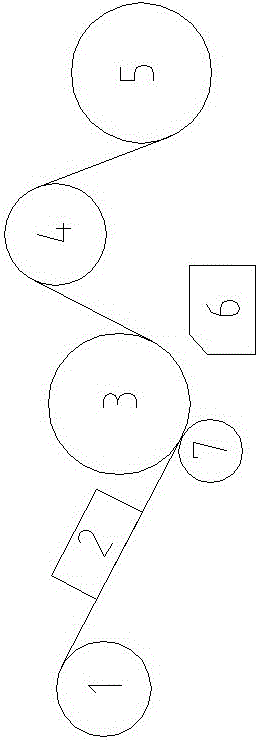

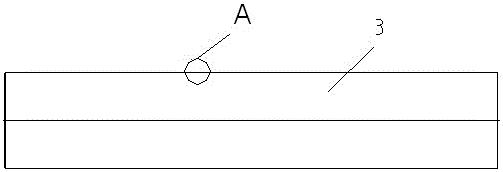

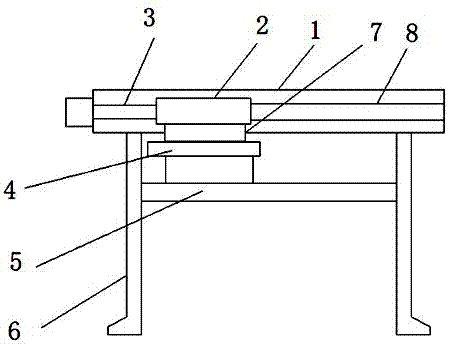

Manufacturing technology of mini type paper handkerchiefs

ActiveCN103342007BIncrease productivityHigh speedPaper/cardboard articlesFolding thin materialsManufacturing technologyPulp and paper industry

A manufacturing process of miniature paper handkerchief comprises the steps of feeding paper, embossing, longitudinally folding, transversely folding, separating sheets and packaging. By means of a longitudinal-folding unit (1), a transverse-folding unit (2) and a flower disc unit (5) mounted on a machine platform and connected in sequence, paper webs are sequentially tensioned on and arranged to go through the longitudinal-folding unit (1) and transverse-folding unit (2). The paper webs are folded in Z-shaped along the width direction to form three folding surfaces through the longitudinal-folding unit (1), and then folded in half twice along the length direction to form four folding surfaces through the transverse-folding unit (2). The manufacturing process of miniature paper handkerchief presents the advantages of high production efficiency, fast speed, and reduced production cost, and the produced paper presents the advantages of suitable to adjust the specification, convenient to carry, small and exquisite.

Owner:中顺洁柔(四川)纸业有限公司

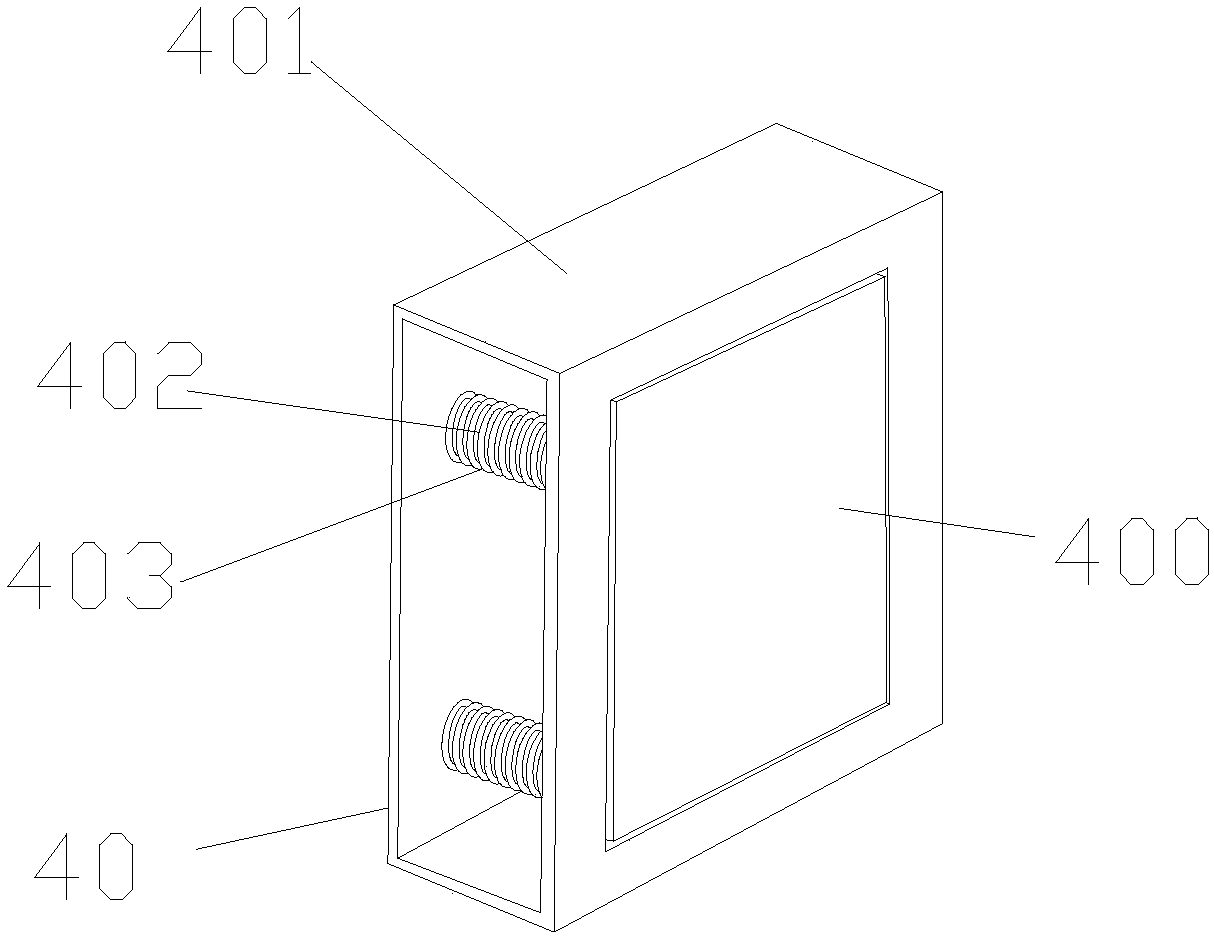

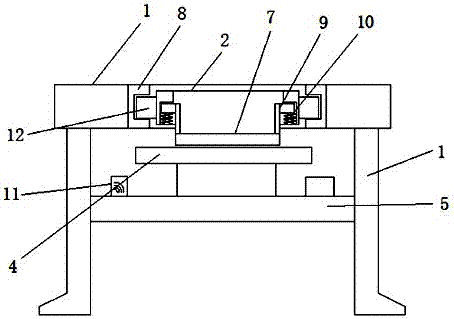

Drilling clamp for machining

InactiveCN107717538AReduce operational burdenReduce manual proceduresPositioning apparatusMetal-working holdersDrillMachining

The invention discloses a machined drilling jig, the structure of which comprises a fixed base, a jig, a fixed plate, a fixed frame, and a connecting spring. Above the inside of the fixed frame, the connecting spring is arranged on the inside of the fixed frame, the fixed base is arranged under the fixed frame through the fixed plate, the fixed frame is vertically connected above the fixed base, the fixed plate is connected in parallel with the fixed base through the fixed frame, and the clamp is connected with the fixed plate through the fixed plate. The fixed frames are connected, the fixed plate is provided with tightening nuts and connecting blocks, the connecting block is fixed on the top of the fixing plate through nuts, and the tightening nuts are screwed on the inside of the upper part of the fixing plate through the connecting block with threads. When the hole fixture is used in processing, the connecting rod can be fixed by fixing the buckle, which reduces the manual operation procedure, reduces the operating burden for the operator, and is conducive to the improvement of work efficiency.

Owner:上海瓜齐电子科技有限公司

A silicon carbide production line

The invention relates to the technical field of silicon carbide smelting, in particular to a silicon carbide production line which comprises a smelting furnace and a chute feeder, wherein an exhaust hole is formed in the upper part of the smelting furnace; a feeding hole and a discharge hole are formed in the lower part of the smelting furnace; a slag outlet is formed in the bottom of the smelting furnace; the chute feeder is positioned below the slag outlet; an inner cylinder of which the size can be freely adjusted is arranged inside the smelting furnace; the bottom surface of the chute feeder adopts a horizontal surface; a high-temperature chain chopper is arranged inside the chute feeder; a material trolley is arranged at the front end of the high-temperature chain chopper in a conveying direction; an exhaust pipe is arranged at the exhaust hole; the exhaust pipe is arranged on the outer wall of the smelting furnace in a spiral manner; a purification device is connected to the free end of the exhaust pipe; a communicating tube is arranged on the purification device; a turbine is connected with the free end of the communicating tube; an air pump is arranged on the communicating tube; the high-temperature chain chopper is driven by the turbine. By adopting the silicon carbide production line, not only is furnace slag automatically cleaned, so that a step of manually shoveling off furnace slag is canceled, but also the silicon carbide which is smelted inside a furnace body can be rapidly cooled.

Owner:秦皇岛市军之友装具有限公司

Three-dimensional corrugated steel production technique and special device thereof

ActiveCN101450359BImprove stamping efficiencyImprove stamping precisionPunchingManufactured material

The present invention provides a process for producing three-dimensional wave steel plates and special equipment thereof. The producing flow of the process comprises: preparing raw materials, machining holes, reeling lugs, reeling arcs, rolling lugs, punching waves and stacking. The special equipment of the process is formed by sequentially connecting a punching press, a beading machine, a plate reeling machine, a lug rolling press, an overturning mechanism and a wave punching press through a producing and conveying chain, wherein a wave punching protecting mechanism is arranged on the wave punching press. The process adopts PLC programmable control technology on a production line, so as to improve the punching efficiency and precision of holes and waves on the three-dimensional wave steelplates. The visualized screen operation of the process realizes the integrated control of a system; at the same time, through establishing a fault mode, every node in the process of production is monitored, so that the reliability and the intellectualization level of the whole system are improved. At the time of improving production efficiency and finished product quality, manual operation procedures are reduced and labor strength is reduced.

Owner:GUANGZHOU MILITARY AREA AIR FORCE ENG CONSTR BUREAU PLA

An automatic detection method for insulator anomalies based on integrated classifier online learning

ActiveCN108765373BImplement fault diagnosisReduce manual proceduresImage enhancementImage analysisPattern recognitionImage manipulation

The invention discloses an automatic detection method for insulator abnormality based on online learning of an integrated classifier. The specific steps are as follows: a high-definition pan-tilt camera is mounted on an unmanned aerial vehicle / pole tower as a carrier, and an image of a visible light insulator of a transmission line is taken, and the obtained image is processed. Preprocessing, image segmentation, image multi-feature extraction, etc., to obtain various typical features of abnormal insulator images and normalize them; then select a decision tree as a weak classifier, and use the normalized features as its classification attributes to train the weak classifier , repeat the training to obtain several decision trees and their classification weights, and finally generate a strong classifier with high classification accuracy through weighted voting. At the same time, combined with online learning technology, the strong classifier is updated in time, and various types of abnormal insulator images are separated for subsequent processing. . The principle of the invention is simple, intuitive and easy to implement, combined with the image processing technology and the machine learning algorithm to intelligently identify and diagnose the abnormality of the insulator, and provides a new idea and method for monitoring the abnormal operation of the insulator.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Flour Production System

ActiveCN104689878BUniform qualityAchieve high integrationCocoaGrain treatmentsQuality levelEngineering

The invention relates to a flour production system. The flour production system comprises a grain storing silo, a first section material lifting machine, a wheat sorting screening machine, a second section material lifting machine, a wheat peeling device, a third section material lifting machine and a millstone flour mill, which are arranged in sequence. A discharging end of the grain storing silo is connected with an input end of the first section material lifting machine, an output end of the first section material lifting machine is connected with an input end of the wheat sorting screening machine, an output end of the wheat sorting screening machine is connected with an input end of the second section material lifting machine, an output end of the second section material lifting machine is connected with an input end of the wheat peeling device, an output end of the wheat peeling device is connected with an input end of the third section material lifting machine, and an output end of the third section material lifting machine is connected with an input end of the millstone flour mill. The flour production system is simple in structure and scientific and reasonable in design. According to the flour production system, the flour production process and the processing process are integrated together, the high integration of flour production is achieved, the time and the labor are saved, plenty of manpower and material power are saved, the working efficiency is improved, and the product quality level is improved.

Owner:LIXIN DONGHUA FLOUR

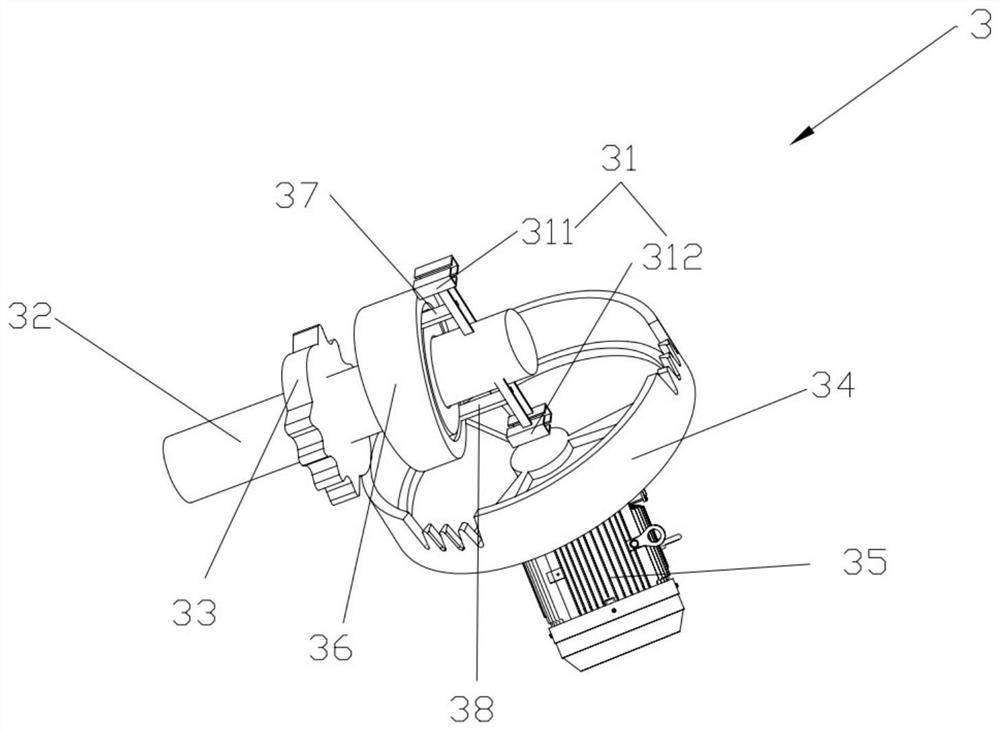

Automatic bolt feeding device and positioning method thereof

InactiveCN113526078AAvoid stackingEasy to installMetal working apparatusConveyor partsGear wheelEngineering

The invention discloses an automatic bolt feeding device and a positioning method thereof, and belongs to the technical field of bolt assembling. The automatic bolt feeding device comprises a base as well as a vibration assembly and a sorting assembly which are mounted on the base; the vibration assembly comprises a vibration disc base mounted on the base, a controller mounted on the vibration disc base, and a spiral hopper fixedly mounted on the vibration disc base; the sorting assembly comprises a material receiving channel making contact with the surface of the end of a feeding channel of the spiral hopper, a rotating shaft fixedly mounted on the material receiving channel through a mounting frame, an incomplete gear mechanism mounted at the end, close to the spiral hopper, of the rotating shaft, a rotating disc in intermittent meshing connection with the incomplete gear mechanism, and a servo motor used for driving the rotating disc to rotate. Bolts can be quickly adjusted to be in the same form, and the bolts can be conveniently mounted.

Owner:NANJING YUSHENG ROBOT CO LTD

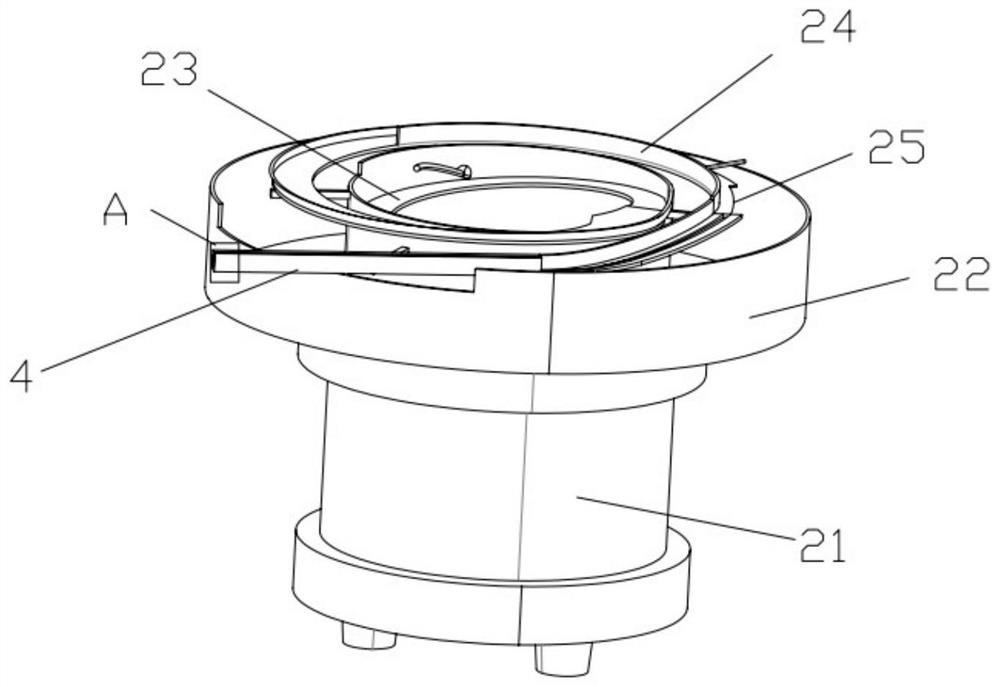

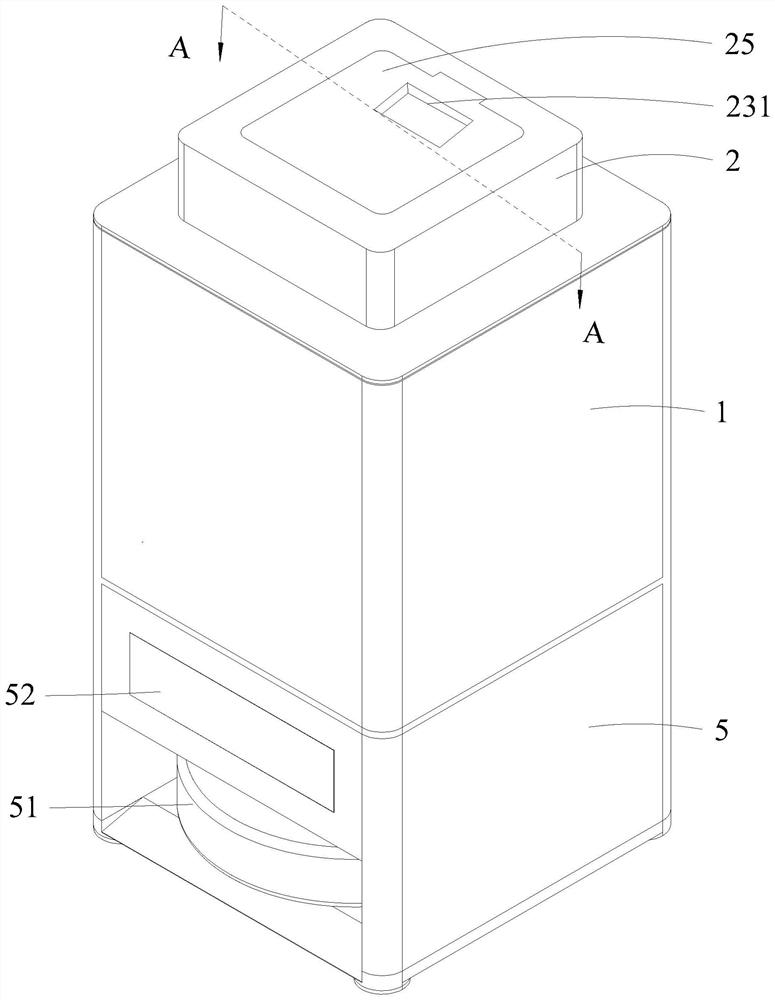

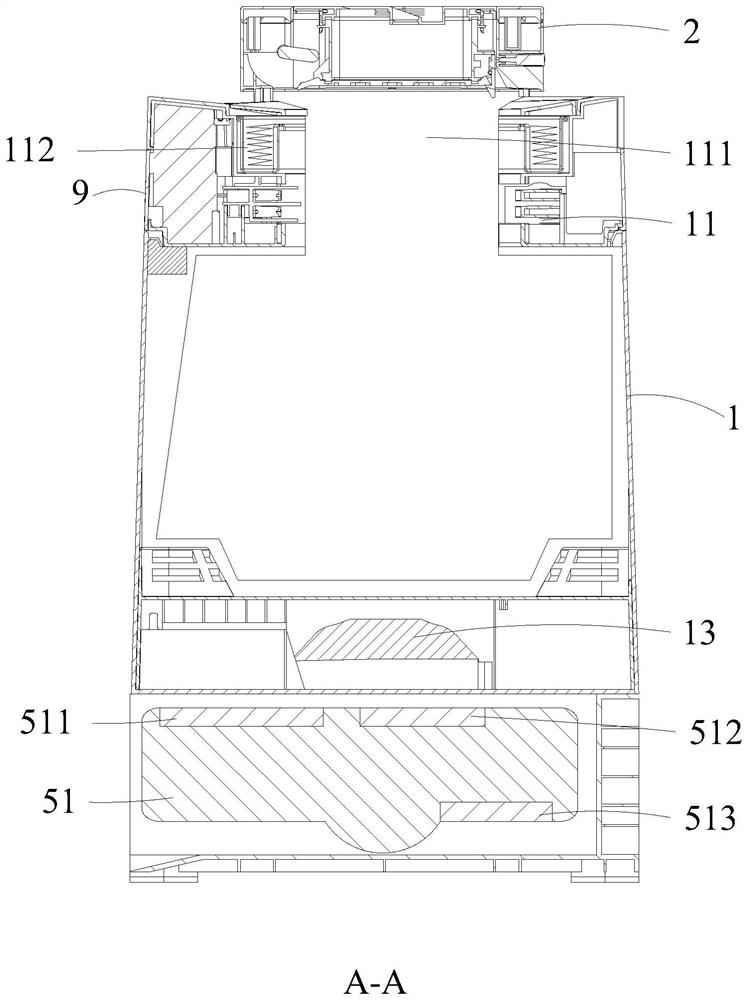

Garbage can with garbage suction function

PendingCN114735376AImprove absorption efficiencySave spaceWaste collection and transferRefuse receptaclesMechanicsWaste management

The invention relates to the field of household cleaning electric appliances, in particular to a garbage can with a garbage suction function, which comprises a can body for containing garbage, the can body is provided with a throwing port for throwing garbage, and the garbage can further comprises a dust collection assembly, a fan assembly and a butt joint port for being connected with an external component, when the external part is connected with the butt joint opening, the dust collecting assembly and the can body are in a non-communicating state, and the draught fan assembly absorbs garbage in the external part into the dust collecting assembly. The garbage in the external connection part can be sucked, and it can be ensured that secondary pollution is avoided in the garbage sucking process.

Owner:LESHOW ELECTRONICS TECH CO LTD

Cold-pressing system and process of cold-pressed microlens grating

ActiveCN104228074BLittle flexibilityIncrease production capacityOptical articlesDiffraction gratingsGratingEngineering

A cold-pressing system for cold-pressing microlens gratings, which sequentially includes a PET film substrate roller, a glue spreader, a grating mold roller, a transmission roller, and a finished product receiving roller, and a pressing roller and a curing light box device are arranged below the grating mold roller. Because the present invention adopts the cold-pressing system technology of the cold-pressed microlens grating, it is convenient for self-production and automatic control, reduces the manual operation procedure, ensures the consistency of the product, and eliminates the factors of thermal expansion and contraction, so the process is simple, The data is accurate, the material is less elastic, the three-dimensional effect is strong, and the cost is low.

Owner:HENAN SANYANG PHOTONICS

Transportation device based on Internet of Things

InactiveCN107499901AShorten the timeSave the weighing processConveyor partsThe InternetTransport engineering

The invention discloses a transportation device based on the Internet of Things, comprising a transportation platform and supporting legs, two sets of supporting legs are fixedly arranged under the transportation platform, two chutes are provided on the transportation platform, and the two chutes The channels of the chute are arranged on the sides of the chute that are close to each other, a movable frame is arranged in the middle of the chute, and two sets of sliders are fixedly connected to both sides of the movable frame, and an opening is opened in the middle of the movable frame. A placement plate is arranged under the movable frame, and two sets of connecting rods are fixedly arranged on the edge of the placing board, and the connecting rods are movably arranged in the movable frame. In the present invention, by setting a pressure sensor, the placement board can be The weight control of raw materials can be carried out during the process of transporting materials, saving the time of weighing materials, and the materials can be controlled during the process of transportation, which saves the process of weighing materials, and also saves manual procedures and saves cost.

Owner:方小玲

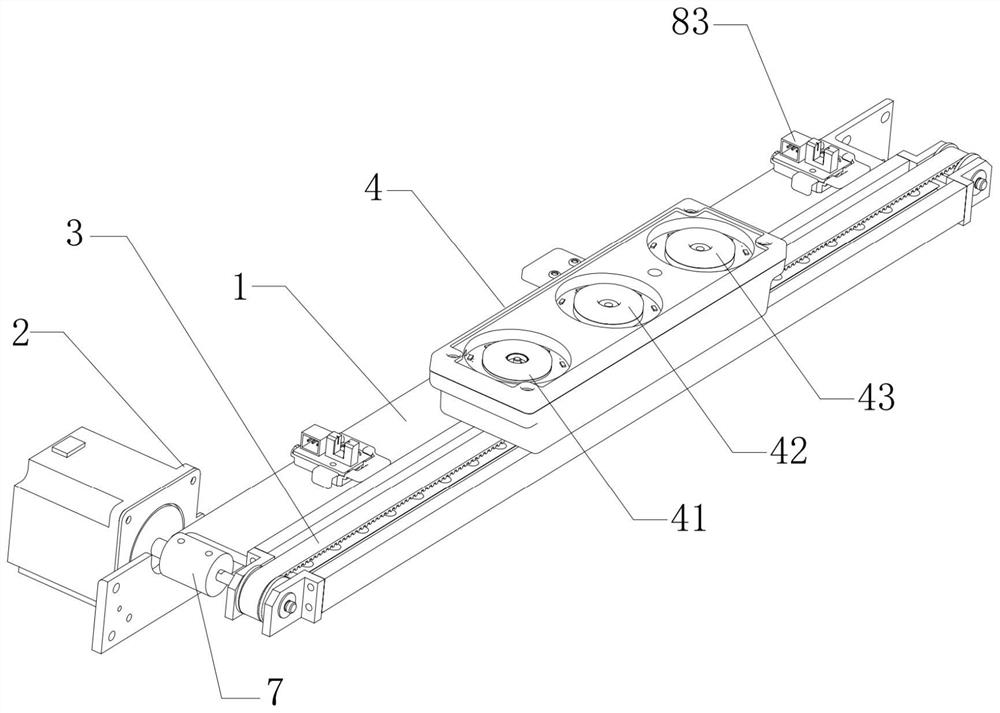

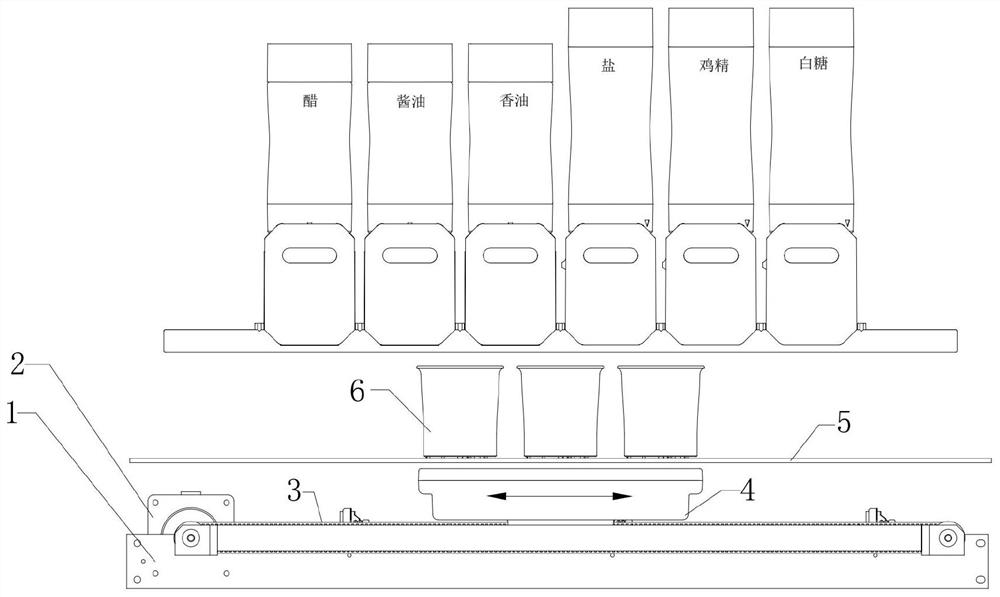

Material receiving device

InactiveCN112374134AAvoid SpillsAvoid problems that affect the taste of dishesControl devices for conveyorsControl engineeringControl circuit

The invention discloses a material receiving device. The material receiving device comprises a support, a power device, a distance measuring device, a synchronous belt, an induction mechanism, a tableboard, a plurality of induction type material receiving cups and a control circuit, wherein the power device and the distance measuring device are fixed to the support, the induction mechanism is fixed to the synchronous belt, the table board is located above the induction mechanism, and the induction type material receiving cups are placed on the table board; the synchronous belt is driven by the power device to move to drive the induction mechanism to move together, and the material receiving cups and the induction mechanism are mutually inducted so that the material receiving cups can synchronously move along with the induction mechanism; the distance measuring device and the power device are both connected with the control circuit; and the distance measuring device measures the distance between the material receiving cups in real time and feeds the distance back to the control circuit, and when the distance indicates that the material receiving cups move to the position under a preset discharging port, the control circuit controls the power device to stop working so that the material receiving cups can receive materials.

Owner:SHENZHEN HUOWANG GAS APPLIANCE

Skipping stitch device of sewing machine

InactiveCN101565882BSkipping effect is stableReduce manual proceduresSewing-machine control devicesLoop takersAutomatic controlEngineering

The invention relates to a skipping stitch device of a sewing machine, which mainly comprises a fixed seat, an eccentric shaft, a rocker, a connecting rod and a deflecting control rod. The fixed seat is combined with a sewing machine body and used for sleeving the eccentric shaft and a torsional spring; the eccentric shaft is inserted into the fixed seat; the rocker is combined with one end of the eccentric shaft, and the other end of the eccentric shaft is combined with a bearded needle table by a ball-and-socket connecting rod; the connecting rod is arranged between a swinging arm on a cross shaft of the sewing machine and the rocker; and the deflecting control rod is arranged at the other end of the eccentric rod. The skipping stitch device can be provided for an operator to control a connecting mechanism by the deflecting control rod to drive a bearded needle to make micrometric displacement, ensures that the bearded needle cannot hook the needle and lines and easily controls the action of a skipping stitch by controlling the deflecting control rod and other automatic control modes, thereby sewing and wrapping operations can be conveniently achieved, the procedures and the time of manual operation can be saved, and operation efficient workers can be increased.

Owner:CHEESIANG SEWING MACHINE S H

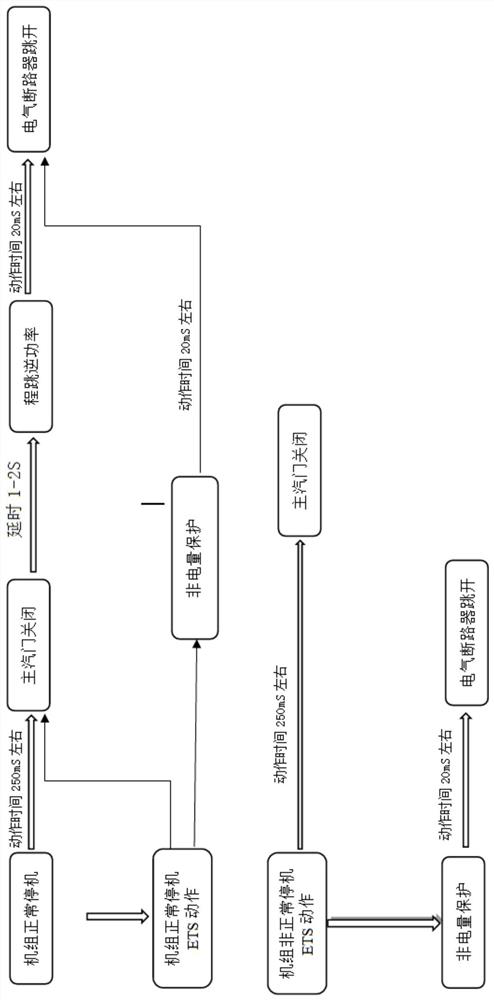

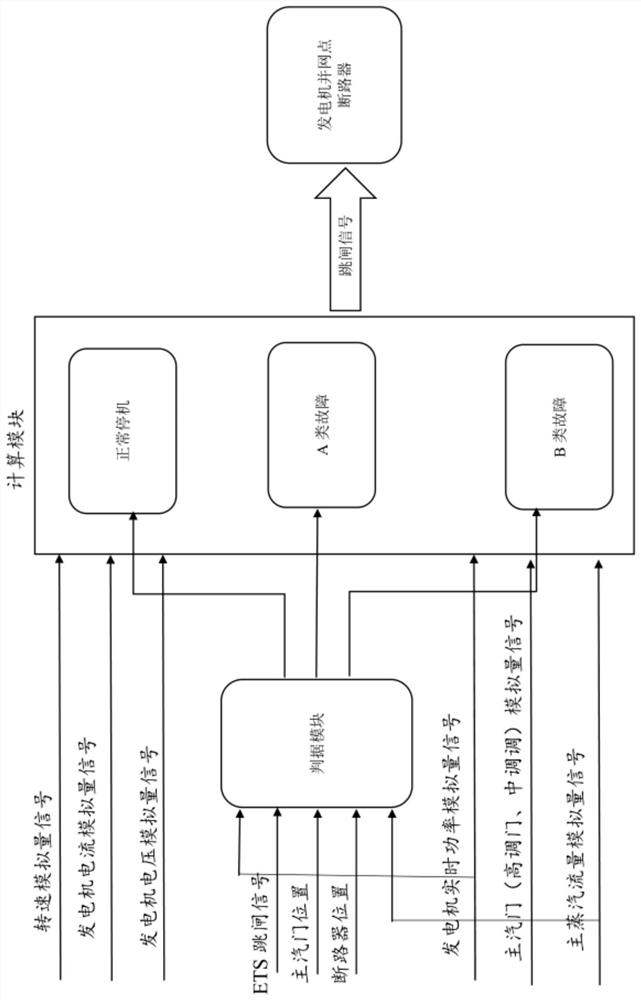

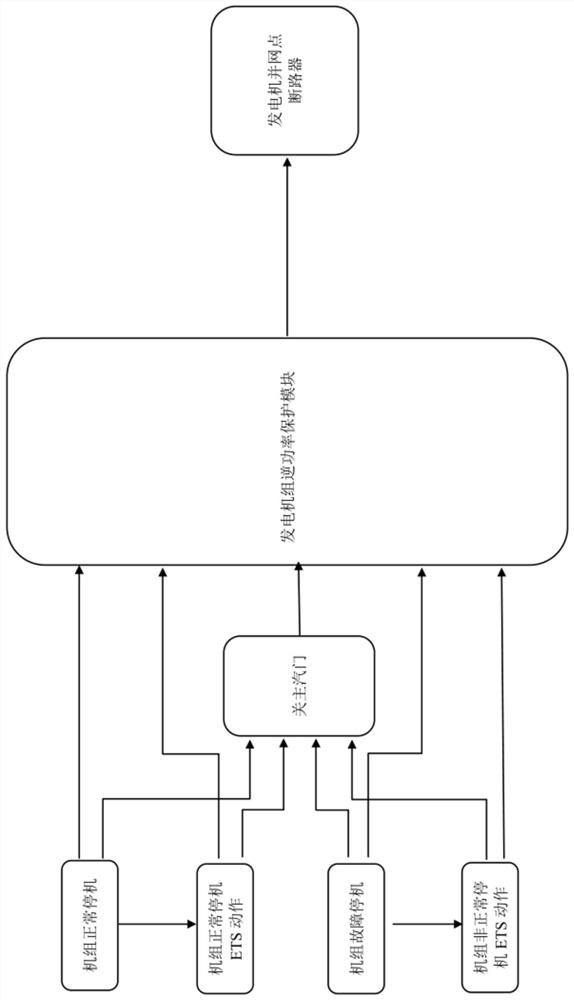

Steam turbine-generator safety protection system and method used in large power plants

ActiveCN110821579BAvoid mistakesAvoid rationalityMachines/enginesSafety/regulatory devicesPower stationControl engineering

The invention discloses a steam turbine-generator safety protection system applied to a large-scale power plant, including a signal acquisition terminal, a criterion module, a calculation module and a generator grid-connected circuit breaker, and also discloses a safety protection system applied to a large-scale power plant The steam turbine-generator safety protection method comprises the following steps of inputting the ETS trip signal, the main steam valve closing signal, and the circuit breaker trip position signal into the criterion module, and the criterion module judges the state type according to the received signal; collects the state type data and the analog quantity The data is input into the calculation module; the calculation module judges the follow-up action according to different state type data and real-time operation data. The criterion module judges the state type through the ETS trip signal, the main steam valve closing signal, and the circuit breaker trip position signal, and the calculation module judges the follow-up action according to the implementation operation data and state type data, so that the steam turbine-generator can achieve redundant release energy and output power grid energy Open the generator circuit breaker after balancing to avoid overspeeding of the generator.

Owner:中国能源建设集团华中电力试验研究院有限公司

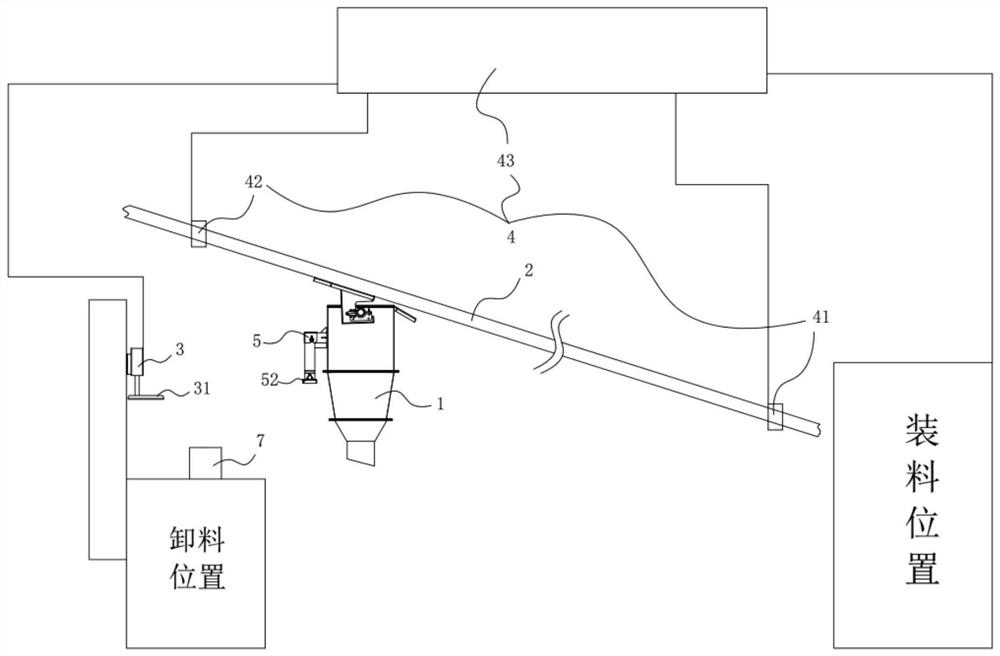

Material conveying system with automatic loading and unloading functions

PendingCN111846999AGuaranteed stabilityGuarantee Occupational HealthLoading/unloadingTransport systemControl system

The invention belongs to the field of automatic equipment, and particularly relates to a material conveying system with automatic loading and unloading functions. The material conveying system comprises a conveying hopper, a guide rail, a triggering device and a control system, wherein the conveying hopper moves between a loading position and an unloading position along the guide rail under the control of the control system; a self-sealing structure is arranged in the conveying hopper, so that the conveying hopper is kept in a self-sealing state in the transportation process; and the triggering device is arranged at the unloading position and is used for breaking the self-closing state of the conveying hopper. The self-sealing structure in the conveying hopper guarantees the stability of material conveying, meanwhile, the dust pollution in the conveying process is greatly reduced, the control system realizes whole-process automatic loading, conveying and unloading, manual operation programs are reduced, the working efficiency is greatly improved, and the occupational health of staff is guaranteed.

Owner:百特(福建)智能装备科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com