Garbage can with garbage suction function

A trash can and garbage technology, applied in the field of trash cans, can solve the problems of cumbersome cleaning steps, bad user experience, dirty garbage collection box, etc., and achieve the effect of reducing operation steps, improving absorption efficiency, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

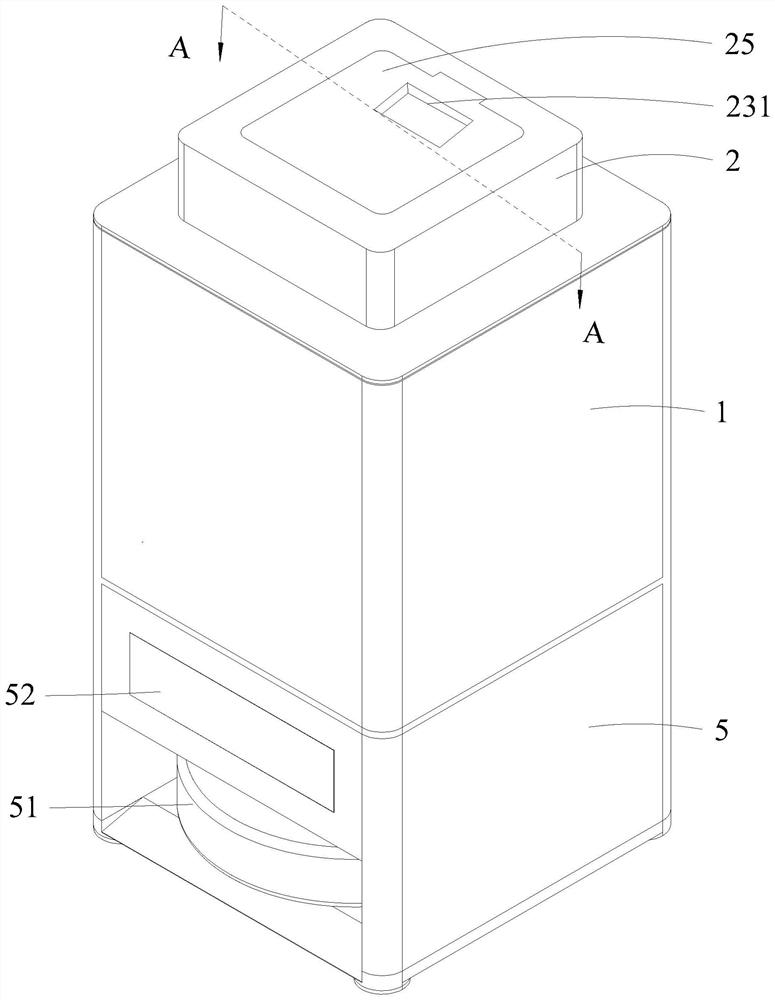

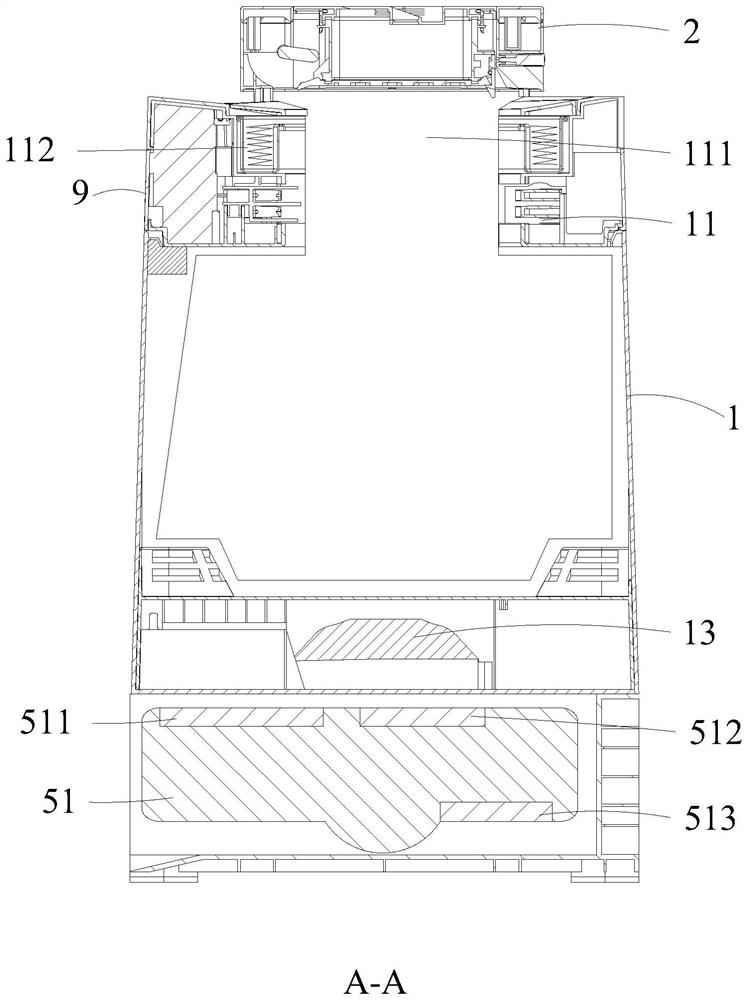

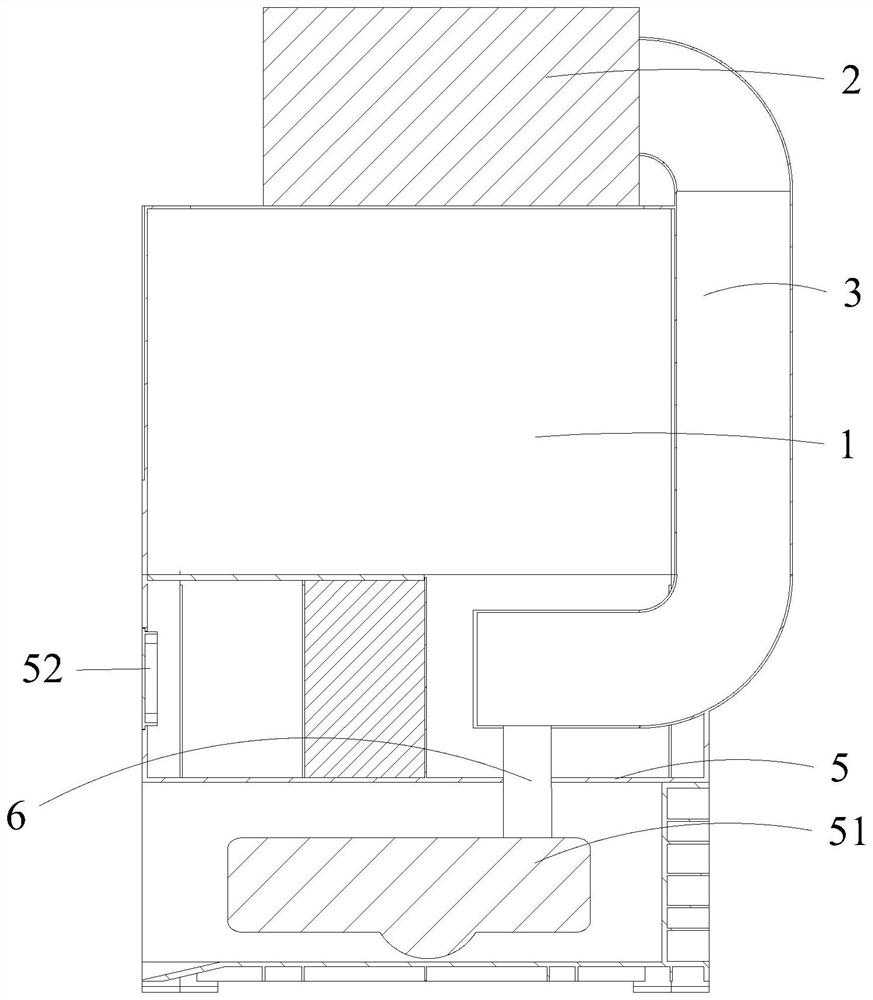

[0040] Please refer to Figure 1 to Figure 3As shown, the trash can of the present application includes a bucket body 1, and the bucket body 1 is provided with a cavity for holding the garbage thrown into the bucket body 1. The bucket is also provided with a dust collecting assembly 2, a docking port 6 for connecting with external components, and a fan assembly. When the external component is connected with the docking port 6, the dust collecting assembly 2 is in a non-communication state with the barrel body 1, and the fan assembly will be connected to the external part. The garbage in the parts is absorbed into the dust collection unit 2 .

[0041] Further, the trash can also includes a connecting pipe 3, and the connecting pipe 3 communicates with the dust collecting assembly 2 and the docking port 6, so that when the external part is connected with the docking port 6, the garbage in the external part is absorbed into the dust collecting assembly by the fan assembly. 2 ins...

Embodiment 2

[0059] In this embodiment, as Figure 1-3 As shown, the trash can further includes a base station 5 disposed below the tub body 1 for supporting the tub body 1, so that the tub body 1 and the base station 5 are arranged up and down, reducing the occupation of horizontal space. The base station 5 can clean and charge the cleaning robot 51, the cleaning robot 51 can automatically clean the room, and then the garbage collected by the cleaning robot 51 is transported to the base station 5, or the user can also place the manually cleaned garbage at the base station 1. The docking interface 6 is used to connect with the cleaning robot 51 , and the docking interface 6 is provided in the base station 5 .

[0060]The base station 5 can be connected to the garbage bin of the sweeping robot 51, and the base station 5 can also be provided with brushes, etc., to gather the garbage collected by the user in the base station 5, and then generate airflow or negative pressure through the fan as...

Embodiment 3

[0063] In this embodiment, as figure 1 As shown, in order to realize the cleaning of the dust collecting assembly, a first pair of interfaces 231 which are matched with the hand-held vacuum cleaner are provided on the dust collecting assembly. More specifically, the upper cover 25 is provided with a first pair of ports 231, and the first pair of ports 231 is adapted to the air inlet of the portable vacuum cleaner. One of the methods is that when the hand-held vacuum cleaner is working, the garbage in the dust-collecting box is sucked away. At this time, the lower cover 22 and the box body 23 are in a buckled state. The hand-held vacuum cleaner cleans the dust-collecting box. When there is a dead corner that is difficult to clean (part of the garbage / dust does not fall into the barrel 1 with gravity), the dust box can be cleaned more cleanly by external suction; another way, the hand-held vacuum cleaner is used as a substitute for the fan assembly. When the cleaning robot 51 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com