Skipping stitch device of sewing machine

A technology for sewing machines and skipping stitches, which is applied in the direction of sewing machine control devices, sewing machine components, sewing machine ring mechanisms, etc., can solve problems such as high cost, unsolvable technical problems, complicated structural design and production of air blowing devices, etc., and achieve increased The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

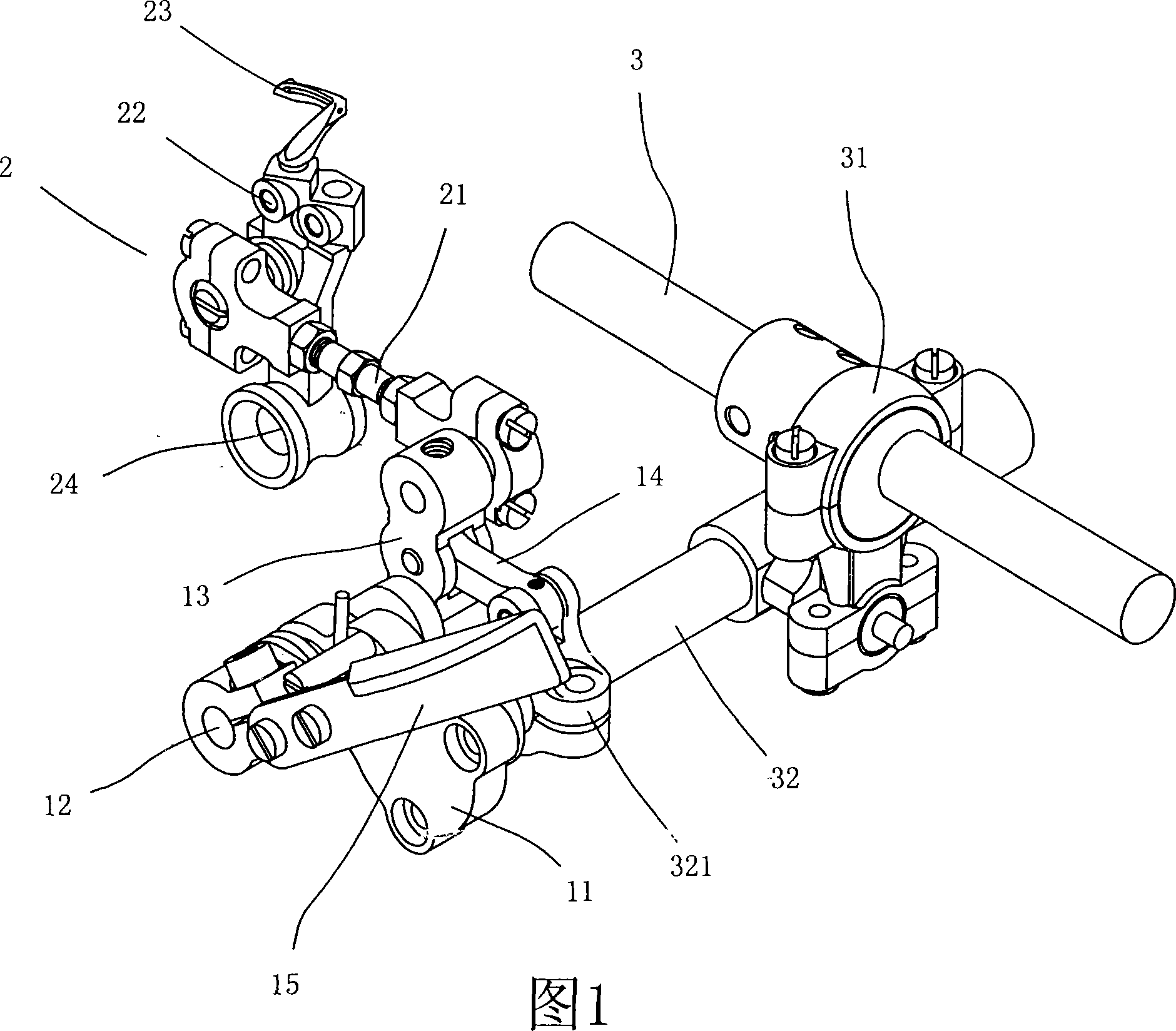

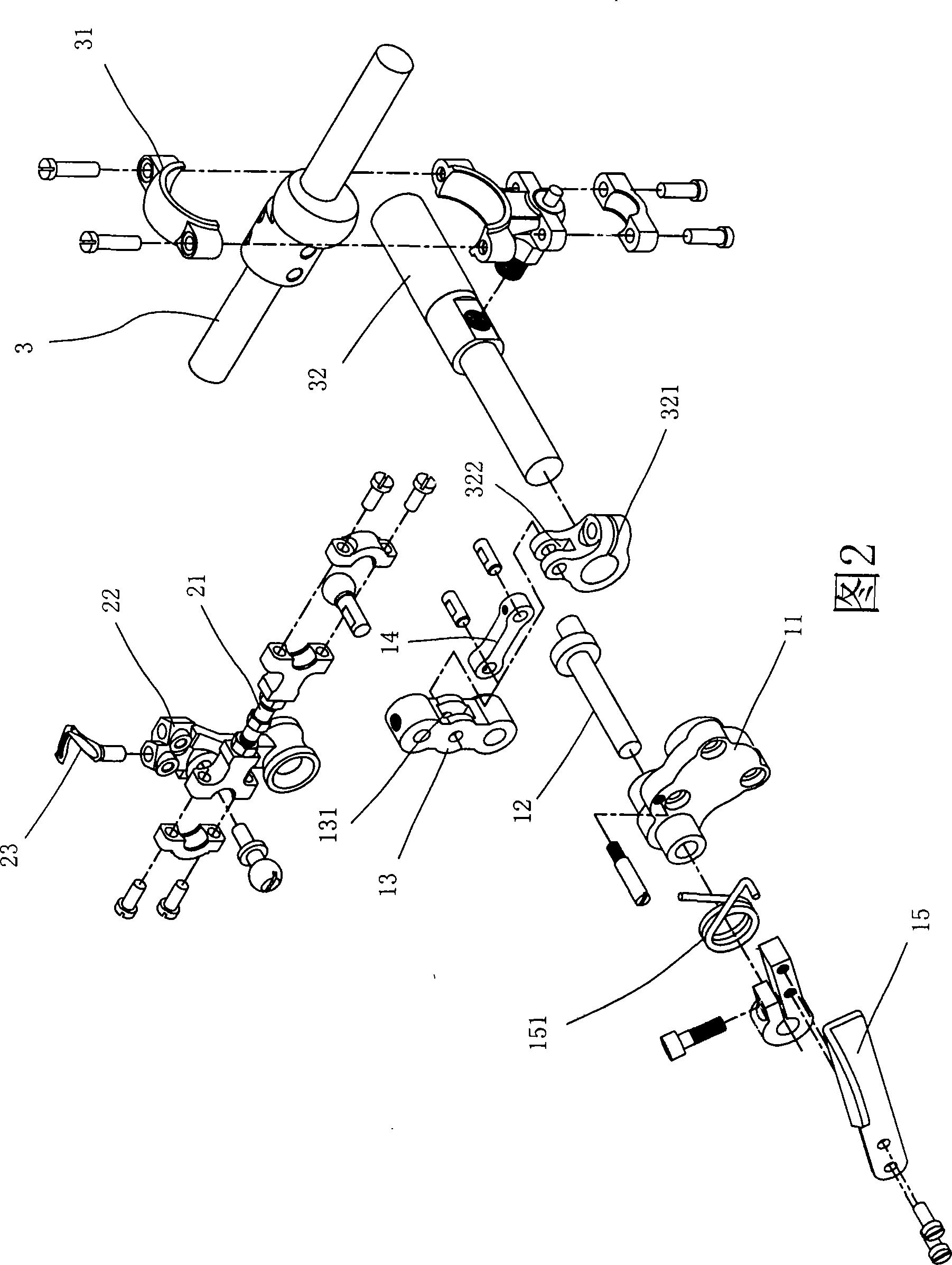

[0052] In order to better understand the technical content of the present invention, use and the effect that can be achieved, all preferred embodiments are listed in detail in conjunction with the accompanying drawings.

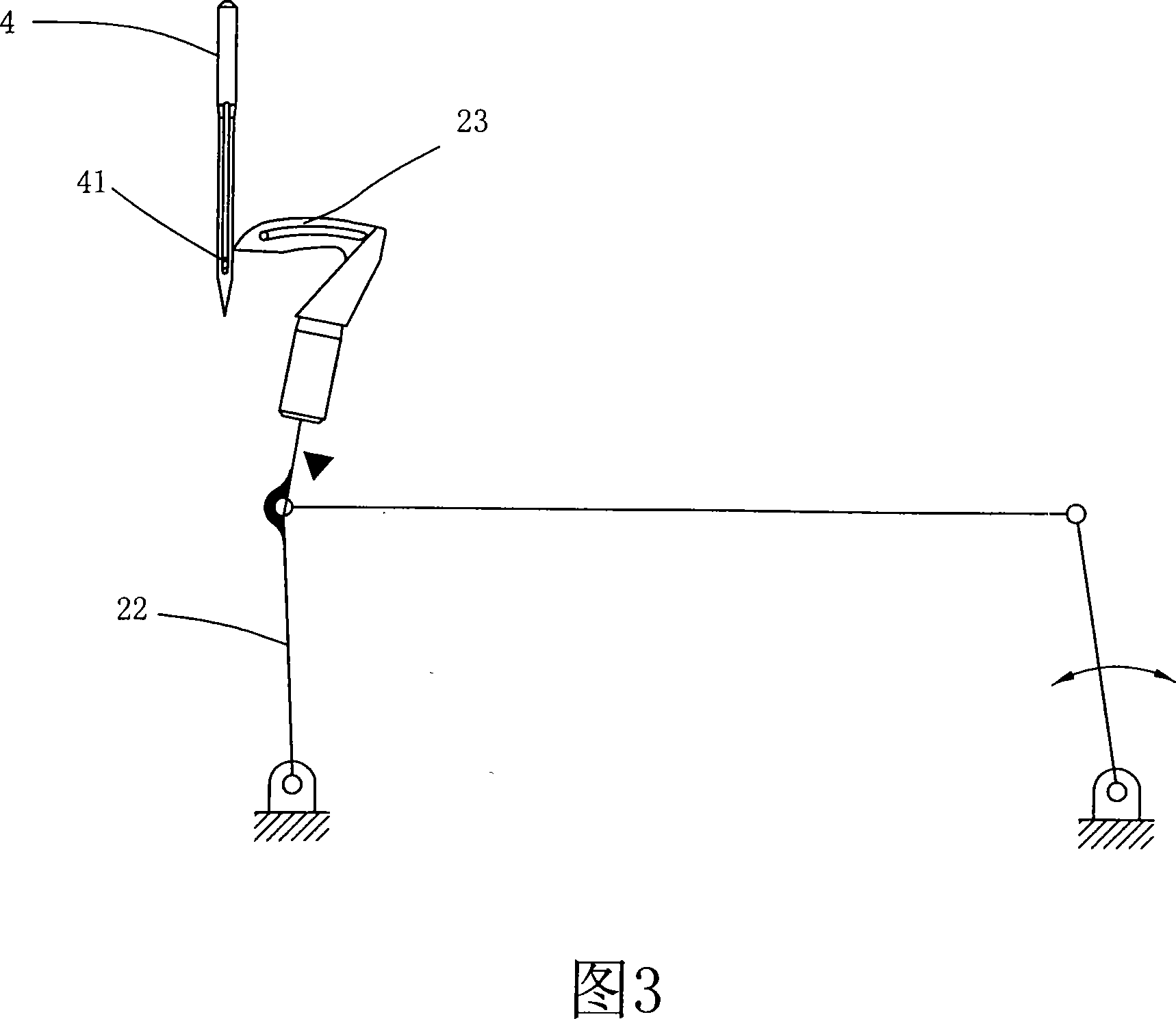

[0053] see figure 1 and 2 As shown, the skipping device of the sewing machine of the present invention is installed in the machine base of the sewing machine, and is used to combine with the hook seat 2 in the machine base, and uses the displacement of the fulcrum of the connecting rod to control the displacement of the hook needle 23 to achieve skipping. function, which includes:

[0054] A fixed seat 11, combined with the sewing machine body;

[0055] An eccentric shaft 12 is passed through the above-mentioned fixed seat 11;

[0056] A rocker 13 is combined with one end of the eccentric shaft 12, and the other end is combined with the hook stand 22 through the ball-and-socket connecting rod 21;

[0057] A connecting rod 14, located between the swing arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com