Material conveying system with automatic loading and unloading functions

A material transmission system, automatic loading and unloading technology, applied in the field of automatic loading and unloading material transmission system, to achieve the effect of ensuring airtightness, ensuring stability, and reducing manual operation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

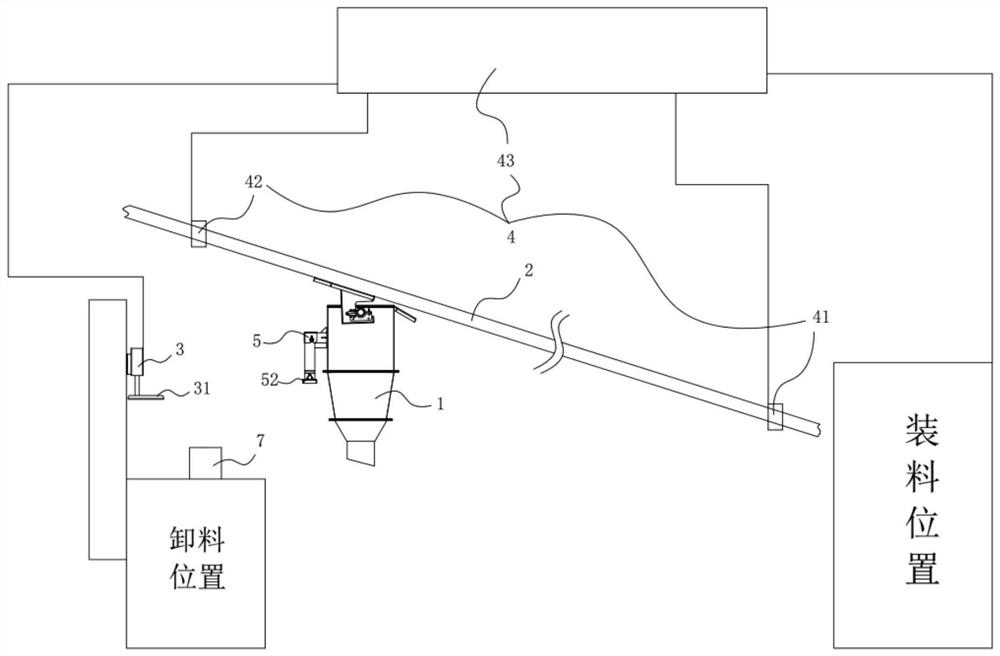

[0027] Such as figure 1 As shown, on the basis of the above, the terminal sensor in this specific embodiment adopts a sensor, and the sensor has the characteristics of simple structure and rapid response. The controller 43 is electrically connected to the first sensor 41 , the second sensor 42 and the trigger device 3 respectively. The control system 4 has a simple structure and is easy to control, and the electrical connection method ensures the stability of the control signal.

[0028] Guide rail 2 can select synchronous belt guide rail for use. The synchronous belt transmission has the advantages of accurate transmission ratio, no slip, constant speed ratio, stable transmission, vibration absorption, low noise and wide range of transmission ratio.

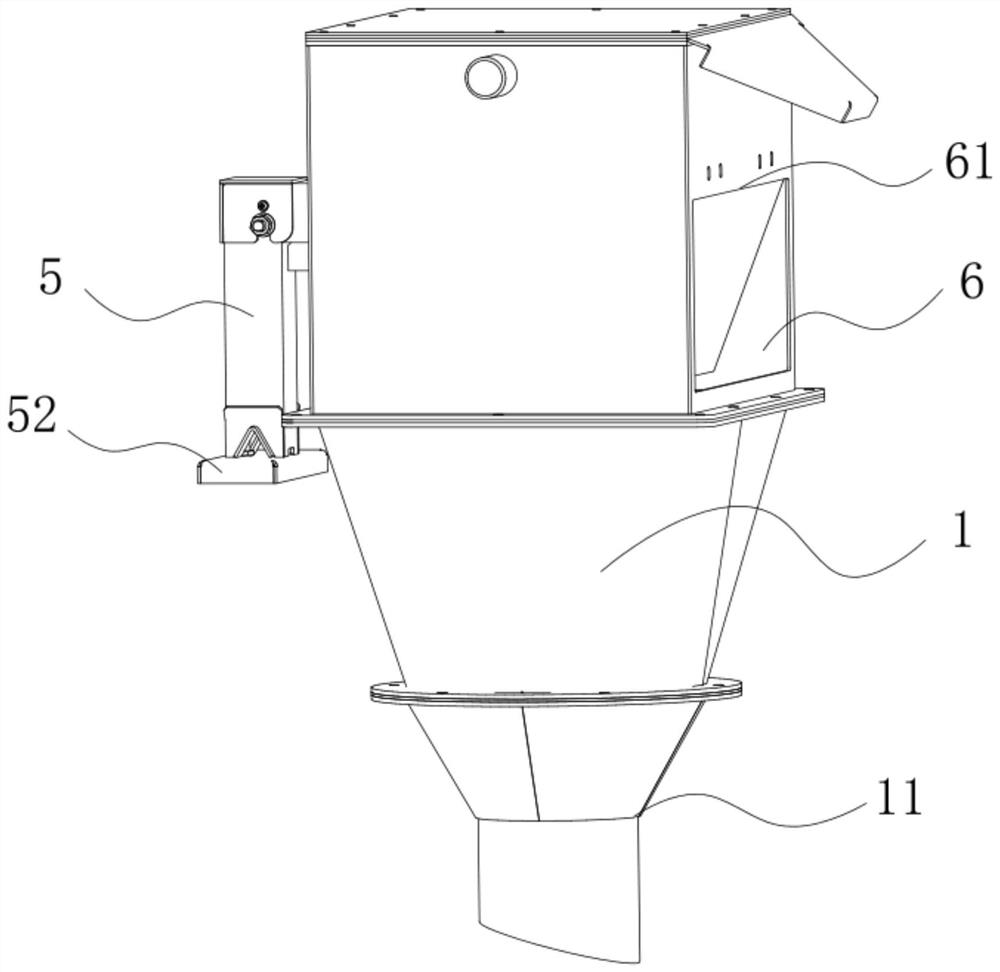

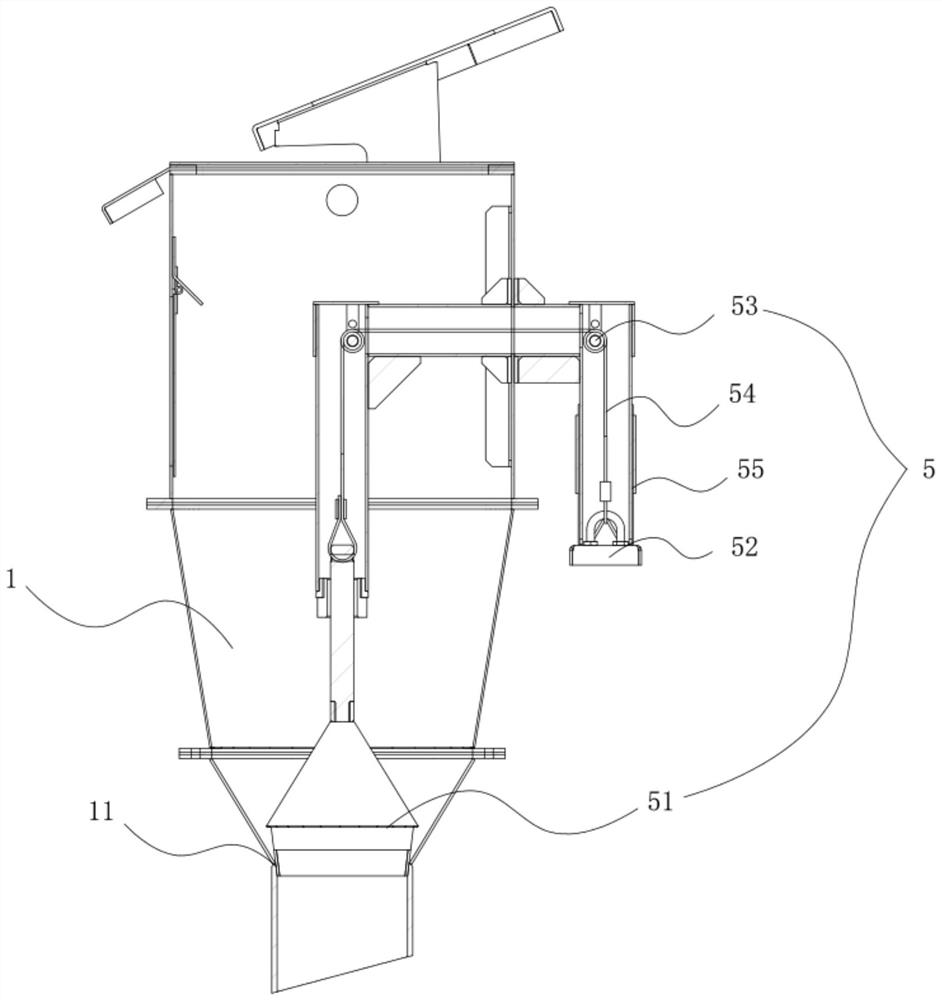

[0029] The triggering device 3 is a cylinder, and a push plate 31 is arranged under the cylinder 3 , and a trigger area for pushing the push plate 31 is arranged on the triggered device 52 . When the cylinder 3 receives the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com