Material receiving device

A technology of material receiving device and material receiving cup, which is applied in the direction of conveyor control device, transportation and packaging, conveyor objects, etc., which can solve the problems of cumbersome procedures and achieve the effect of reducing manual procedures and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

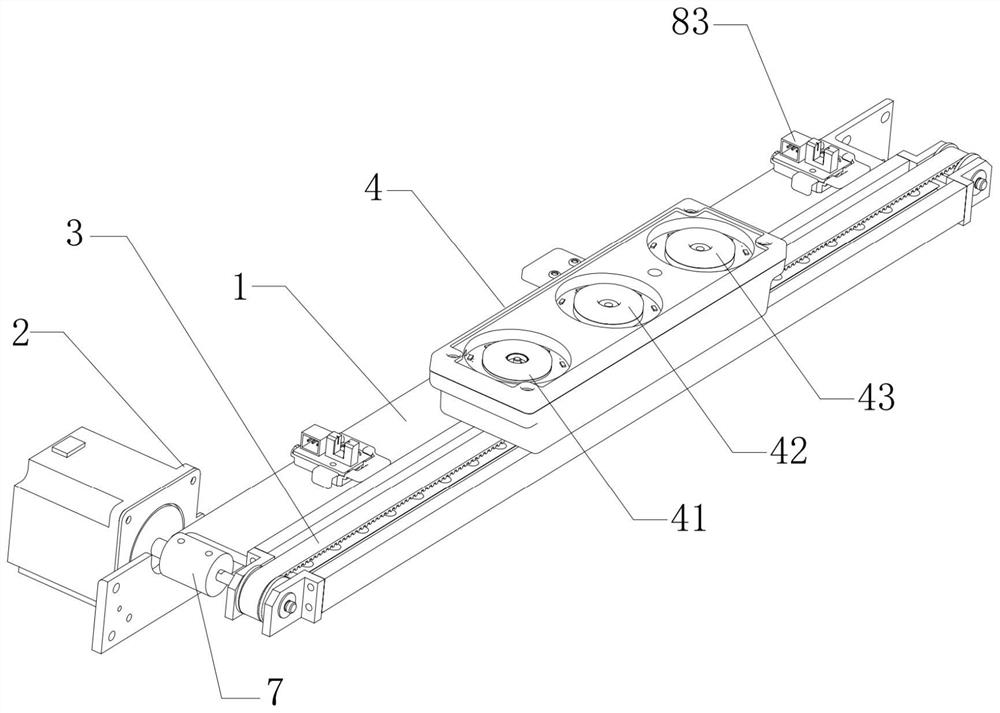

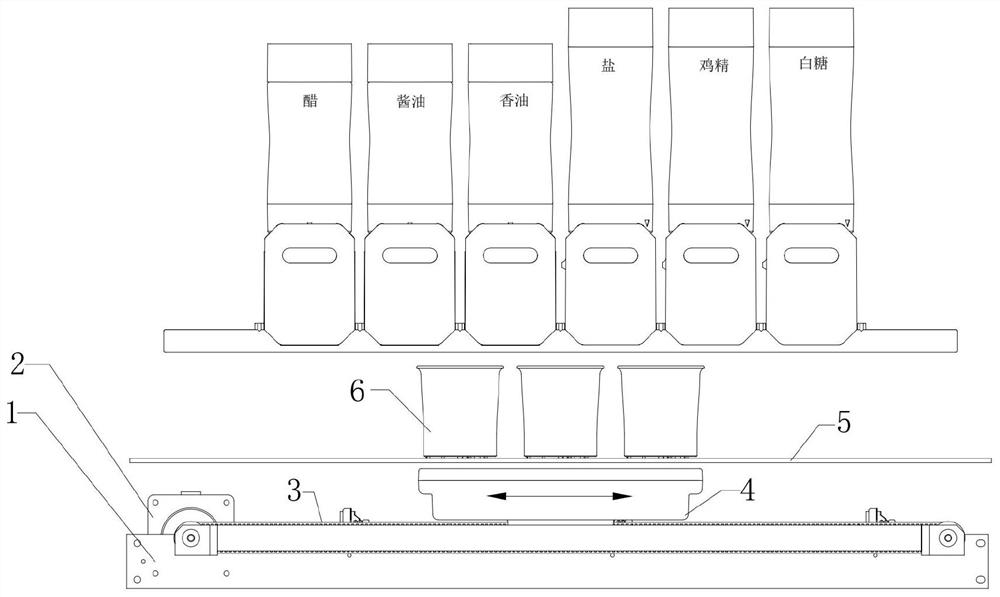

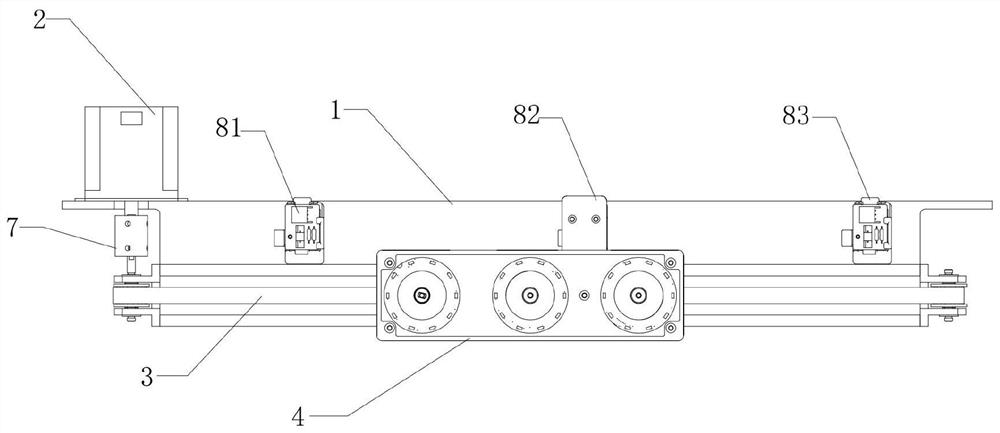

[0021] The specific embodiment of the present invention provides a material receiving device for cooking in the kitchen, which is used for receiving seasoning under the outlet of the seasoning (especially the outlet of the automatic feeding device). refer to Figure 1 to Figure 3 , the material receiving device includes a bracket 1, a power unit 2, a synchronous belt 3, an induction mechanism 4, a fixed table 5, several inductive material receiving cups 6, a distance measuring device and a control circuit. The power unit 2 can be a stepping motor, for example, and the synchronous belt 3 is connected with the stepping motor through a shaft coupling 7, so that the synchronous belt 3 can be driven to move when the stepping motor is running, such as when the stepping motor is running forward The timing belt moves to the left (based on the front vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com