Flour Production System

A production system and flour technology, applied in cocoa, grain processing, food science, etc., can solve the problems of undiscovered patent publications, poor flour quality uniformity, waste of manpower and material resources, etc., to save manpower, uniform quality, and energy saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with embodiment, the present invention is further described; Following embodiment is illustrative, not limiting, can not limit protection scope of the present invention with following embodiment.

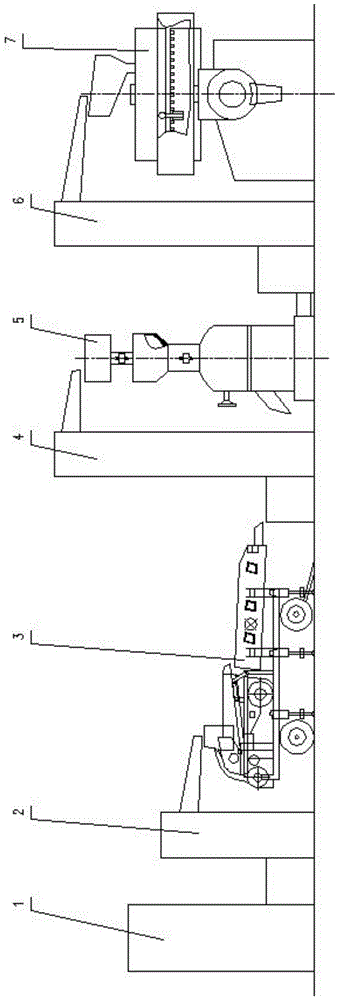

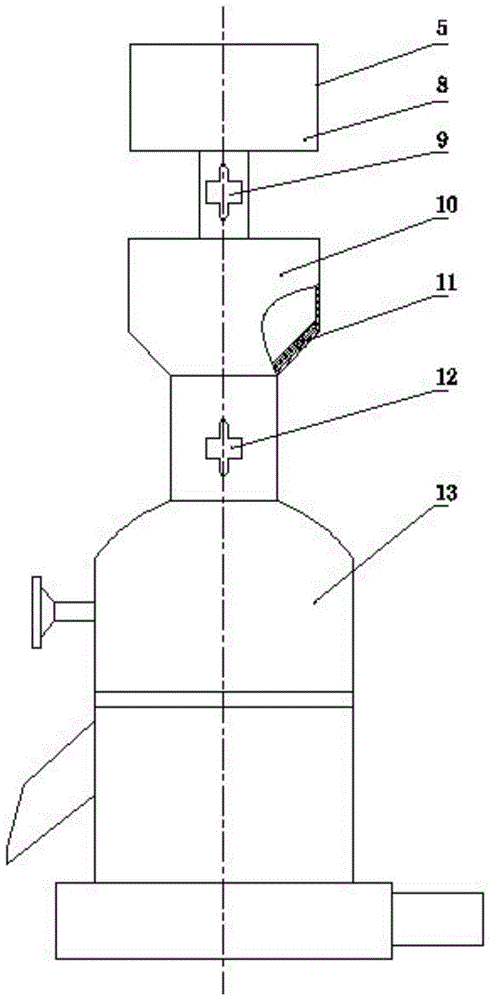

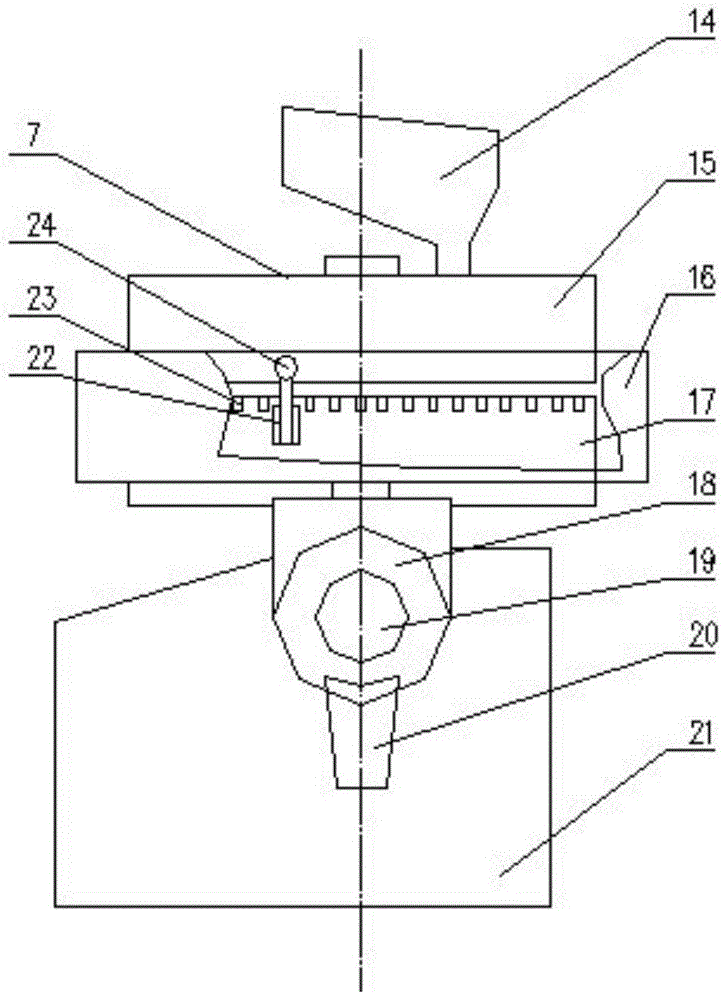

[0026] A flour production system such as figure 1 As shown, it includes a grain storage bin 1, a first-stage feeder 2, a wheat cleaning and screening machine 3, a second-stage feeder 4, a wheat peeling device 5, a three-stage feeder 6 and a stone mill flour machine 7 arranged in sequence. The discharge end of the grain storage bin is connected to the input end of one section of feeder, the output end of this section of feeder is connected to the input end of wheat cleaning and screening machine, and the output end of wheat cleaning and screening machine is connected to the second section of feeding machine. The input end, the output end of the two-stage feeder is connected to the input end of the wheat peeling equipment, the output end of the wheat peelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com