Cold pressing system and technology of cold pressing type micro lenticulation

A technology of microlens grating and cold pressing, which is applied in the direction of diffraction grating, optics, optical elements, etc., can solve the problems of not being able to provide high-quality materials, data deformation and error, and inaccurate data for naked-eye 3D displays, so as to facilitate self-production Production and automation control, elimination of thermal expansion and contraction, and accurate data effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

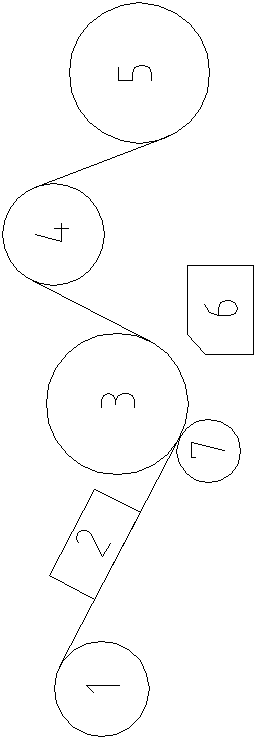

[0017] Embodiment 1: as figure 1 As shown, a cold-pressing system of a cold-pressed microlens grating includes a PET film substrate roll 1, a glue spreader 2, a grating mold roll 3, a transmission roll 4, and a finished product receiving roll 5 in sequence. A pinch roller 7 and a curing light box device 6 are arranged below the grating mold roller. The grating mold roll adopts the steel roll of ¢100-?600, L=1300-2000mm.

[0018] Such as Figure 4 , 5 As shown, the curing light box device 6 includes a box body 6-7 with a specification of 1800*700*500mm made of a cold-rolled steel plate of 0.2-1.2 mm, and the inside of the box body 6-7 is fully covered with reflective film; the inside of the box body 6-7 A 1500-2200W high-pressure mercury lamp 6-1 is provided, and is lit by the LC series resonance power supply method; an arc-shaped reflector 6-2 is installed at 100-200mm on one side of the high-pressure mercury lamp 6-1; Install thermometers or automatic temperature alarm de...

Embodiment 2

[0019] Embodiment 2: A cold-pressing process of a cold-pressed microlens grating, the cold-pressing system of the cold-pressed microlens grating is the same as that in Embodiment 1. Adopt the normal temperature cold press production method, under the condition that the cleanliness of the dark room is required to be ≦100, the PET film bypasses the PET film substrate roller, glue coating machine, grating mold roller, transmission roller and finished product receiving roller in turn; glue coating The ultra-transparent UV photosensitive adhesive with a light transmittance of more than 99% is selected in the machine, and the PET film is pressed between the grating mold roller and the pressure roller, and the pressure is adjusted to 0.5-1.50KG; the coated PET film is cured after passing through When the light box is installed, it is directly irradiated with a high-pressure mercury lamp to cure instantly, and the temperature in the curing light box device is controlled at 25°C-30°C; t...

Embodiment 3

[0021] Example 3: A cold-pressing system and process of a cold-pressed microlens grating, using a PET substrate (coil) of 1800*100000mm, requiring cleanliness ≦100 in a dark room, room temperature; 21°C±°C, relative humidity; (68—78)%, the ventilation volume; (0.2—0.4)m3∕S, the production of naked eye 3D47-inch grating materials.

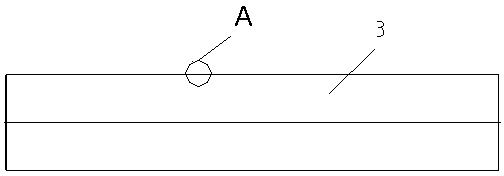

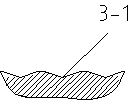

[0022] Select high-quality PET base material (roll material) 1800*100000mm upper roller, positioning, adjust balance, choose such as figure 2 , 3 The grating mold roll 3 shown has an axial groove 3-1 on the surface of the grating mold roll. This process requires the operator to wear anti-static clothing and gloves to prevent scratches and indentations on the PET substrate. After passing the inspection, adopt the method of artificial lamination, pass through the glue applicator, the grating mold roller and the pressure roller, adjust the pressure to 1.0KG, pass through the transmission roller, pass through the curing light box device, and reach the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com