Auger conveying mechanism for dust or particle material storage and transportation container

An auger conveying mechanism and granular material technology, which is applied in the field of storage and transportation containers, can solve the problems of energy consumption and unsatisfactory work, and achieve the effect of energy saving and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

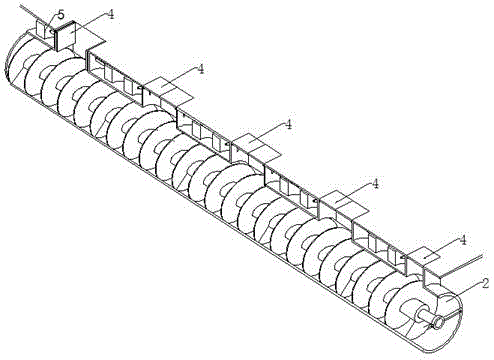

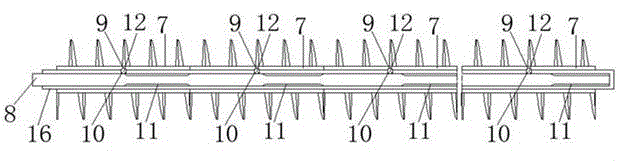

[0042] Such as figure 1 and 2 As shown, the auger conveying mechanism of the dust or granular material storage and transportation container described in this embodiment includes a conveying trough 2 arranged at the bottom of the storage and transportation container, an auger assembly arranged in the conveying trough 2, and the The storage and transportation container is connected with the conveying tank 2 with a plurality of communication holes 3 arranged in rows, wherein the arrangement direction of the communication holes 3 is consistent with the transport direction of the auger assembly, and each communication hole 3 is provided with at least one cover plate 4, and the cover plate 4 can close or open the strip groove or the communication hole 3 under the action of the control assembly; wherein, preferably a plurality of the communication holes 3 along the The transportation direction of the auger assembly is evenly distributed, and two cover plates 4 are arranged in each ...

Embodiment 2

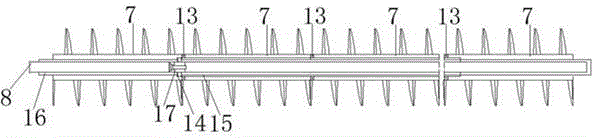

[0055] As a changeable implementation of embodiment 1, such as figure 1 and 3 As shown, the auger conveying mechanism of the dust or granular material storage and transportation container described in this embodiment includes a conveying trough 2 arranged at the bottom of the storage and transportation container, an auger assembly arranged in the conveying trough 2, and the The storage and transportation container is connected with the delivery tank 2, wherein the length direction of the strip slot is consistent with the transport direction of the auger assembly, and at least one cover is provided on the strip slot plate 4, the cover plate 4 can close or open the strip-shaped groove or the communication hole 3 under the action of the control assembly; wherein, in this embodiment, the length of the strip-shaped groove is the same as that of the conveying groove 2 have the same length. In this way, in the actual operation process, the cover plate 4 close to the discharge port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com