A silicon carbide production line

A production line, silicon carbide technology, applied in the direction of silicon carbide, carbide, etc., can solve the problem of sticking to the bottom, side wall or corner of repose of the feeding trough, silicon carbide cannot be cooled rapidly, and waste gas is not reused. Achieve the effects of preventing unsightly appearance, reducing time, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

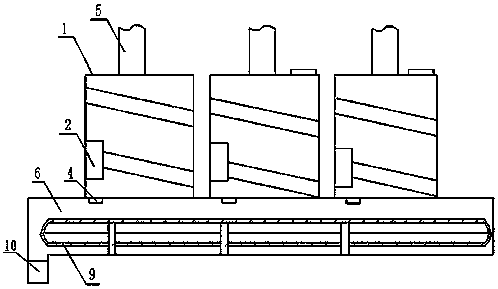

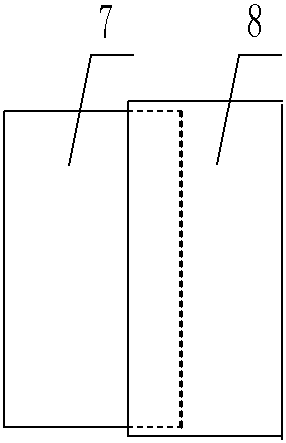

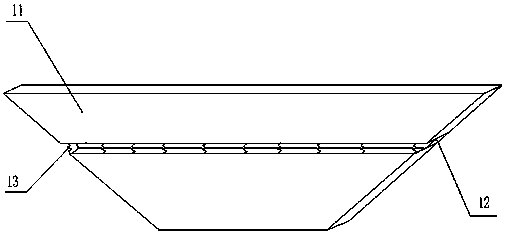

[0032] Reference signs: smelting furnace 1, feed inlet 2, turbine 3, slag outlet 4, exhaust pipe 5, feeding trough 6, left barrel 7, right barrel 8, high temperature chain bucket machine 9, feeding car 10, loading hopper 11, leaf spring 12, spring 13.

[0033] see figure 1 and figure 2 As shown, a silicon carbide production line includes a smelting furnace 1 and a feeding trough 6, and multiple smelting furnaces 1 are arranged side by side; the upper part of the smelting furnace 1 is provided with an exhaust port, and the lower part of the smelting furnace 1 is provided with a feed port 2 and a discharge port. The bottom of the smelting furnace 1 is provided with a slag outlet 4, and the feeding trough 6 is located below the slag outlet 4; the smelting furnace 1 is provided with an inner cylinder, and the size of the inner cylinder can be adjusted freely; in order to realize the free adjustment of the inner cylinder, Divide the inner cylinder into two parts, one is the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com