Three-dimensional corrugated steel production technique and special device thereof

A technology of three-dimensional corrugation and special equipment, applied in the field of corrugated steel plate production, can solve the problems of low production efficiency and machining accuracy, and the production process cannot meet the requirements, so as to improve production efficiency and finished product quality, improve reliability and intelligence level, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

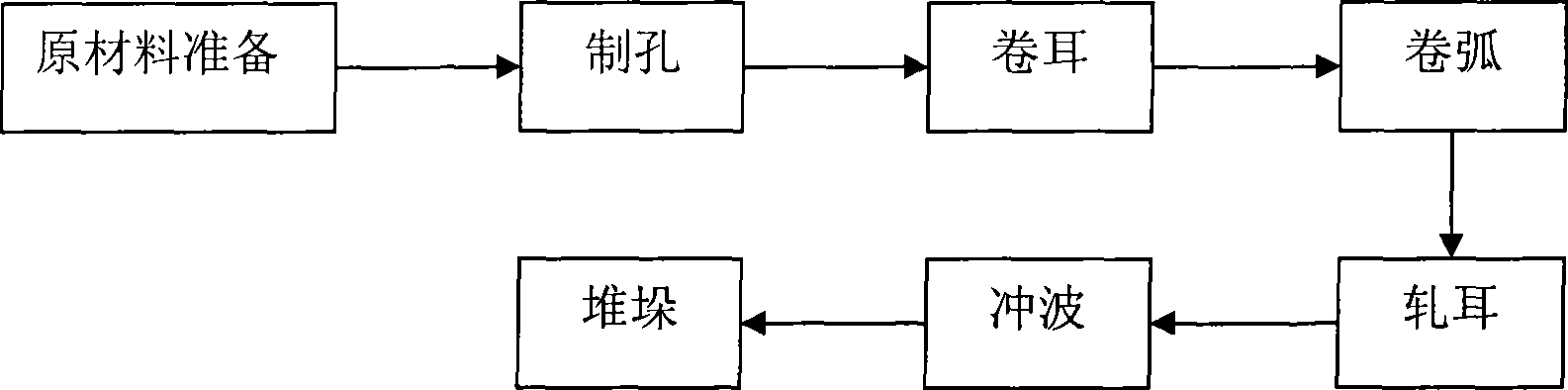

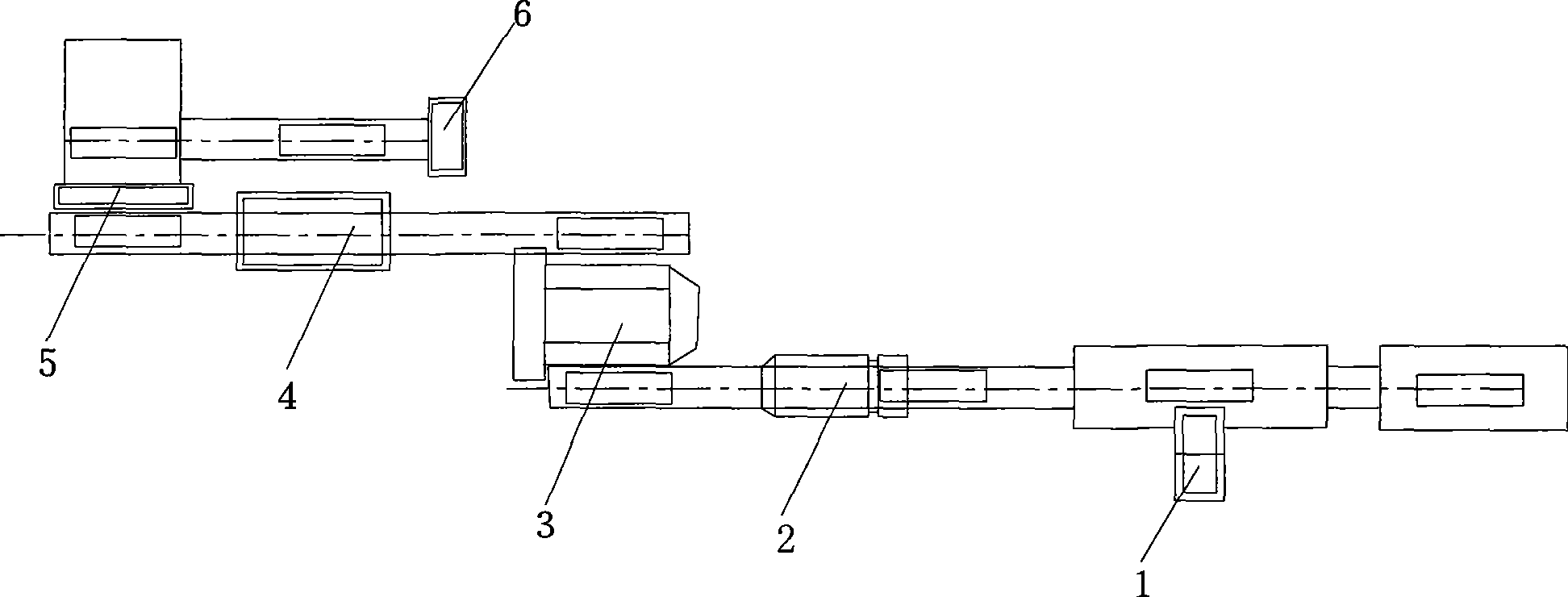

[0027] A kind of three-dimensional corrugated steel plate production technology of the present invention, its flow process is as follows figure 1 shown, including the following steps:

[0028] (1) Raw material preparation, that is, sending steel plate raw materials from the raw material storage area to the preparation area;

[0029] (2) Hole making: Start the production conveyor chain, send the steel plate from the preparation area to the punching machine, and then start the punching machine to punch the steel plate;

[0030] (3) Rolling ear: The production conveyor chain sends the steel plate with the hole made to the edge press machine, and then starts the edge press machine to roll the ear on both sides of the steel plate;

[0031] (4) Curling arc: the production conveyor chain sends the steel plate that has passed the rolling ear to the plate rolling machine, and then starts the plate rolling machine to curl the steel plate, and the steel plate becomes an arched structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com