Power-cut work safety protection system for railway overhead line system

A technology of safety protection and catenary, which is applied to power lines, transportation and packaging, and vehicle parts, etc., can solve the problems of long time for manual dismantling and hanging of ground wires, occupying effective working time, etc., so as to reduce manual operation procedures and improve safety performance, ensuring the effect of grounding reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

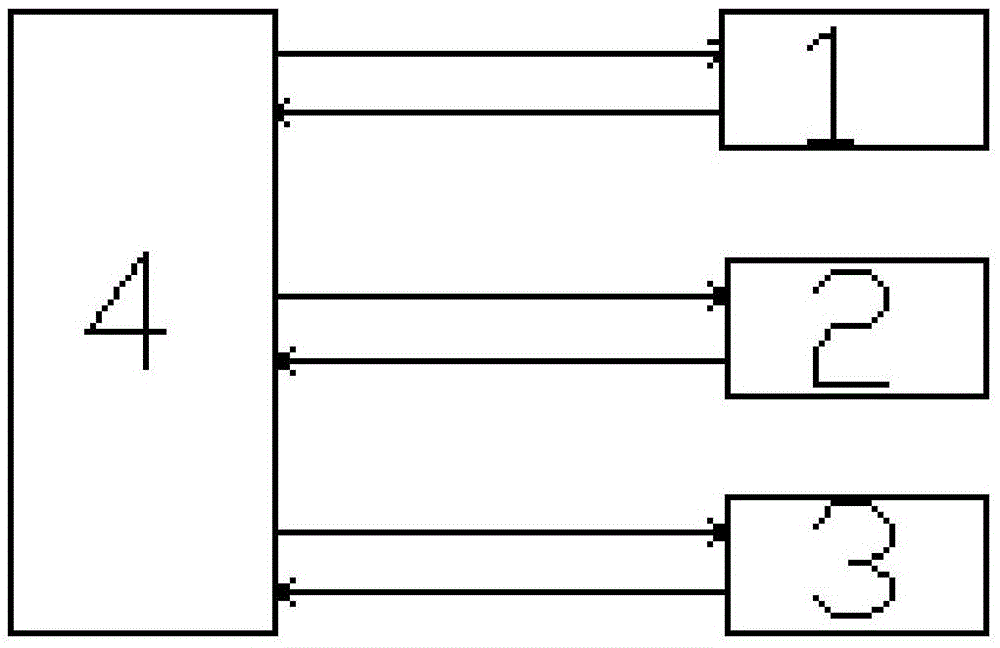

[0028] See attached figure 1 , the railway catenary power outage operation safety protection system includes a grounding line (not shown), a high-voltage electrical inspection device 1, an electric mechanism 2, a grounding detection mechanism 3, a first video monitoring device (not shown), a second video monitoring device ( not shown) and remote control device 4. The grounding line includes a fixed grounding electrode, a high-voltage grounding switch, copper wires and their connecting clamps. The high-voltage grounding switch is set on the copper wire, and the grounding line is used to ground the catenary wire and catenary cable of the catenary. as attached figure 1 As indicated by the arrow in , the high-voltage electroscope 1 receives detection instructions from the remote control device 4 to detect whether the catenary is carrying voltage. Wherein the high-voltage electrometry device 1 detects whether the catenary has voltage after the power failure of the catenary, and ...

Embodiment 2

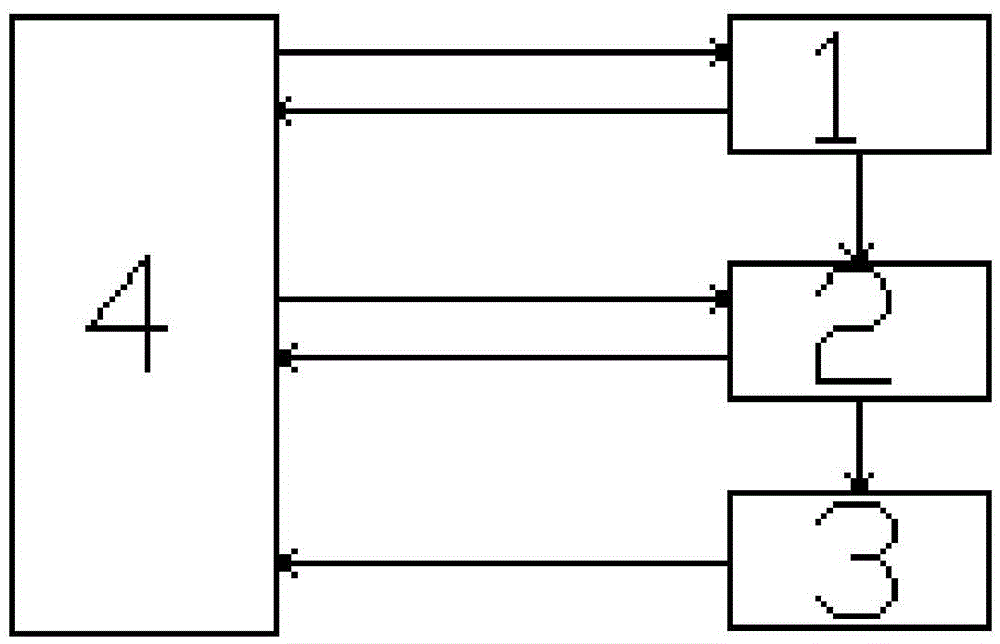

[0032] See attached figure 2 , In another embodiment of the present invention, the railway catenary power outage operation safety protection system includes a grounding line, a high-voltage electroscope 1, a motor mechanism 2, a grounding detection mechanism 3, a first video monitoring device, a first video monitoring device and Remote control device4. The grounding line includes a fixed grounding electrode, a high-voltage grounding switch, copper wires and their connecting clamps. The high-voltage grounding switch is set on the copper wire, and the grounding line is used to ground the catenary wire and catenary cable of the catenary. The high-voltage electroscope 1 receives the detection command from the remote control device 4 to detect whether the catenary has voltage, and when it detects that the catenary does not have voltage after the catenary is powered off, it issues an instruction to the motor mechanism 2 to close the high-voltage grounding switch ; When it is dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com