Glue-extruding device for autosizing flanging machine

An automatic gluing and edge folding machine technology, applied in the application, shoemaking machinery, clothing, etc., can solve the problems of increasing labor costs, prolonging the process time, and not using automatic gluing and edge folding, so as to save labor costs, Improve the speed of gluing and reduce the effect of manual operation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

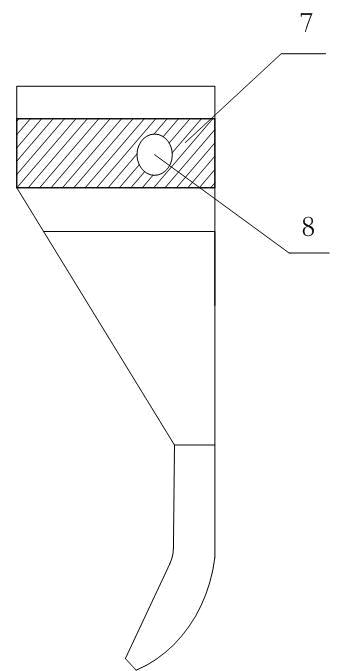

[0025] See attached Figure 4 and Figure 5 Shown is a cross-sectional view and a partially enlarged view of the glue discharge device of the automatic gluing and folding machine of the known technology. The glue spray port of the glue discharge device of the automatic gluing and folding machine of the known technology has only one glue spray hole, and the hot melt glue is coated on the leather product. Although this single-hole gluing device can achieve the purpose of gluing, the mode of this single-hole gluing can only be folded into the reinforcing belt of 2mm width when the leather product is hemmed.

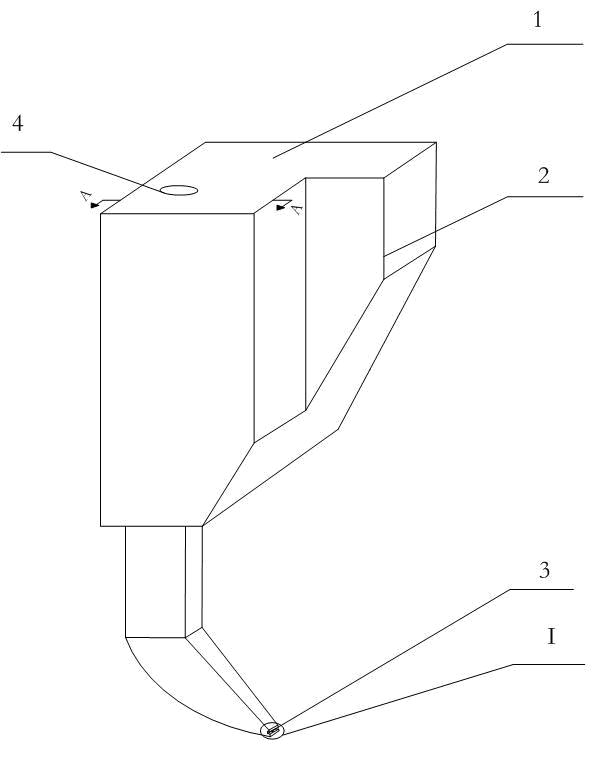

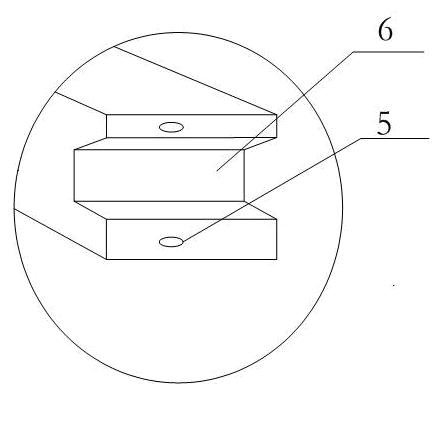

[0026] See attached Figures 1 to 3 and attached Figure 6 and 7 As shown, it is the gluing device of the automatic gluing and folding machine of this embodiment, a kind of gluing device for the automatic gluing and folding machine, including the main body 2, and the main body 2 is provided with the automatic gluing and folding machine. The connection part 1 of the mach...

Embodiment 2

[0032] Compared with Embodiment 1, this embodiment has the same basic structure, the difference lies in that the number of 5 glue spray holes in the glue spray port is 2 or more.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com