Rotary seedling-transplanting hole-digging machine

A rotary and seedling transplanting technology, which is applied in the direction of excavation/covering trenches, application, planting methods, etc., can solve the problems of poor operation accuracy, different depths of soil holes, time-consuming and difficult processing, etc., to achieve mechanization, uniform depth and saving The effect of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

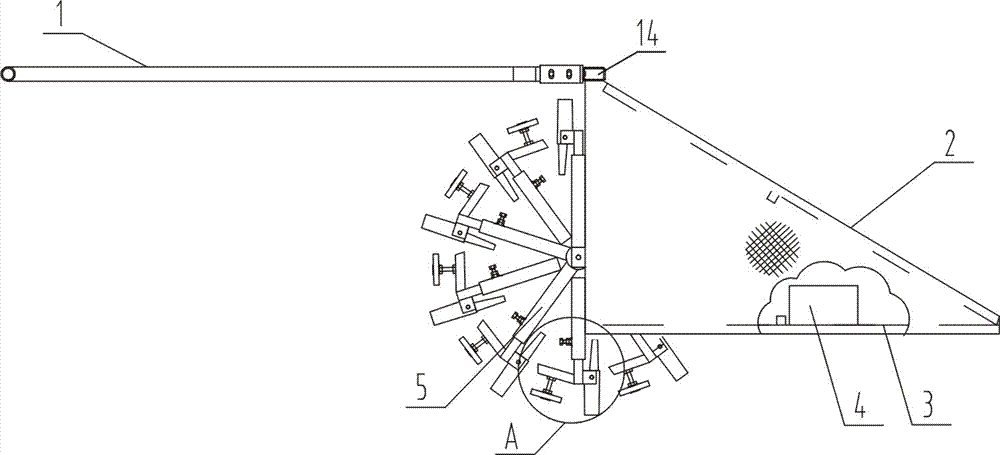

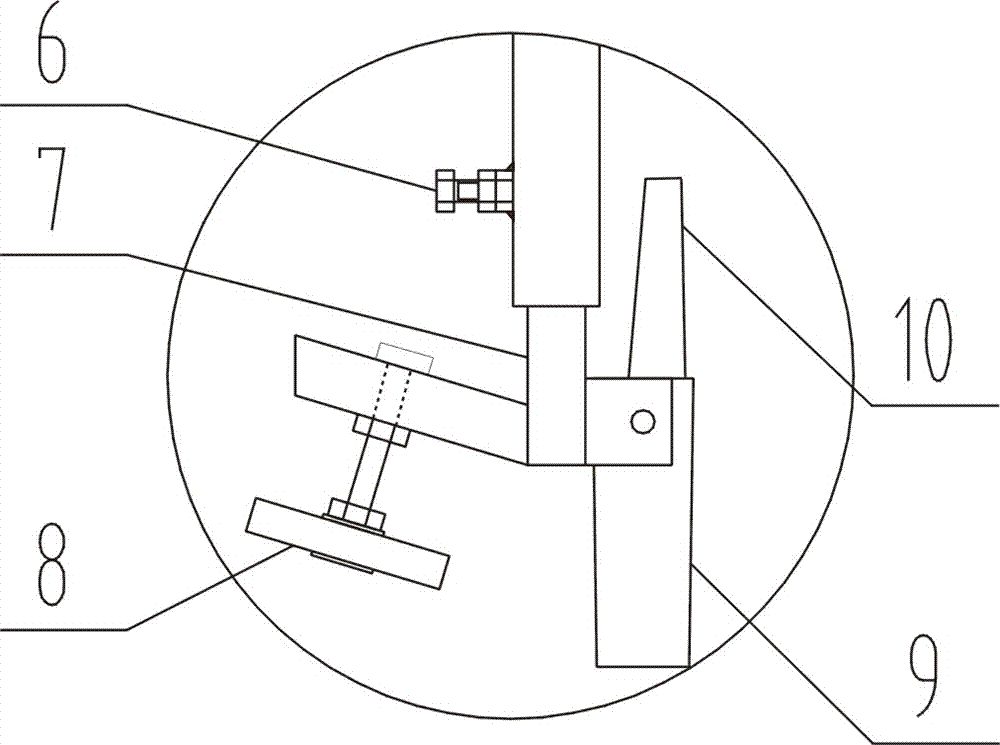

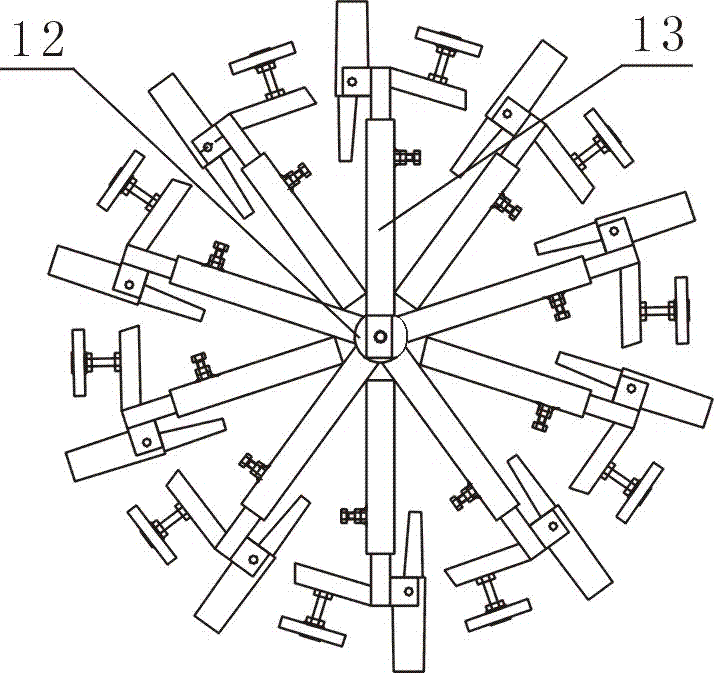

[0020] Now refer to the attached Figure 1-4 , combined with specific methods as follows:

[0021] The rotary seedling transplanting machine includes a handle 1, a main frame 3, a wheel body 5, a telescopic column foot 7, and a soil-taking sleeve 9. The main frame 3 is a frame structure, and the outer layer is covered with a protective shell Be protective cover 2, front end is little, and rear end is big, so that separate nursery stock, be provided with counterweight 4 at described main body frame 3 inner front end, described counterweight 4 can be bound on the main body frame 3, with The weight of the weight 4 can make the soil-taking sleeve 9 pressed into the ground; a hollow sleeve 14 is welded at the upper end of the rear part of the main frame 3, which can be penetrated through a transverse connecting rod to horizontally connect several main frames 3 , to realize a large-area opening hole; a horizontal shaft is welded near the rear end inside the main body frame 3, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com