Ejector for heat or work recovery system and heat or work recovery system

A recovery system, ejector technology, used in the field of heat recovery or work recovery systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

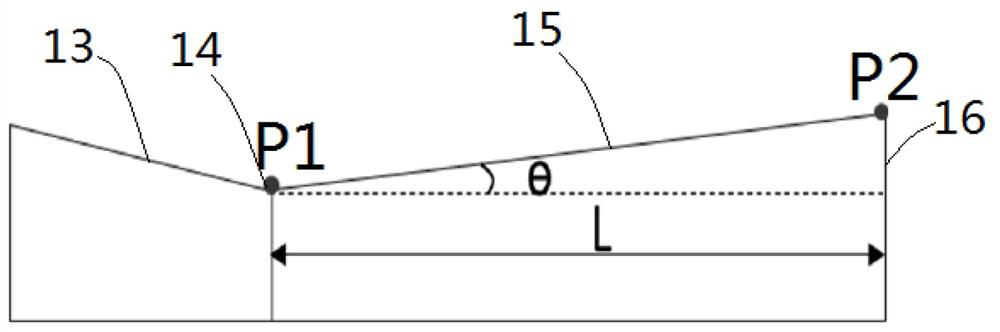

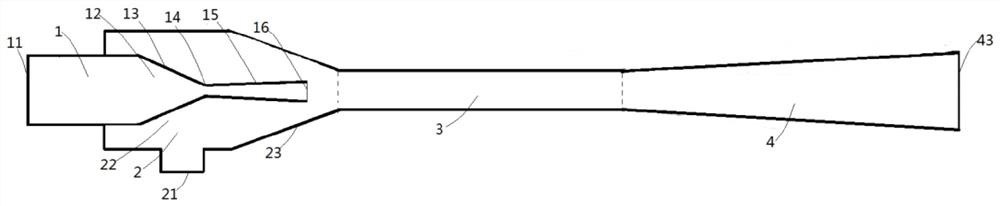

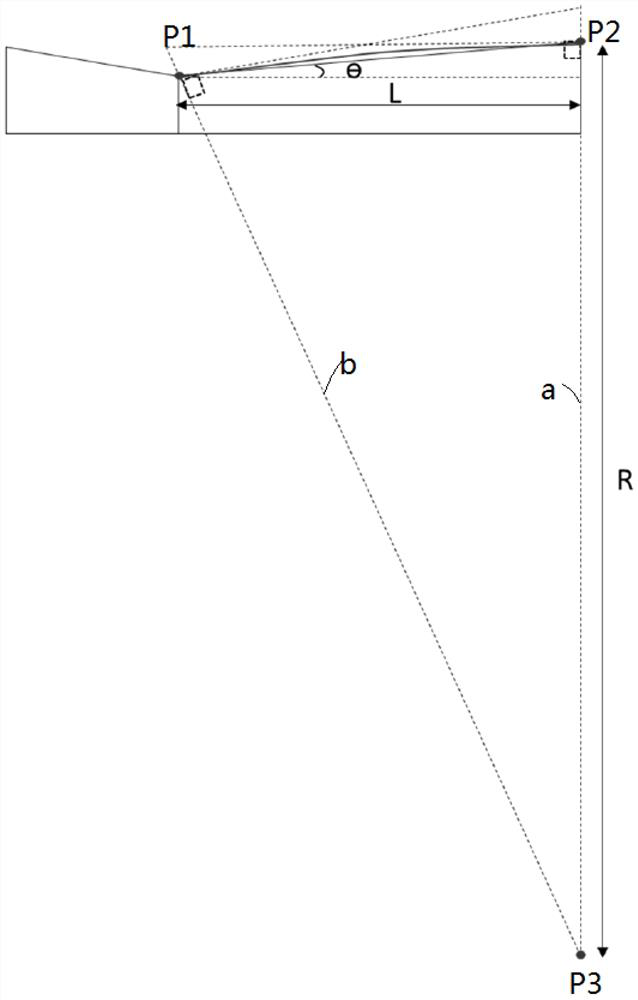

[0028] refer to figure 1 A work recovery system using an ejector according to an embodiment of the present invention will be introduced. For example, it may be a refrigeration device as an example. The work recovery system may include: a compressor 83 , the outlet of the compressor 83 is connected to the inlet of the condenser 82 downstream thereof, and the outlet of the condenser 82 is connected to the high-pressure fluid inlet 11 of the ejector 80 . On the other hand, the fluid outlet 43 of the injector 80 is connected with a separator 84 . Fluid exiting fluid outlet 43 of ejector 80 is separated in a separator wherein the gas phase returns to the inlet of compressor 83 and the liquid phase enters low pressure fluid inlet 21 of ejector 80 after passing valve 85 and evaporator 86 . In the illustrated embodiment, injector 80 is used as figure 1 As shown in the work recovery system, in alternative embodiments, the injector 80 can also be applied to other types of more complex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com