A non-destructive measuring device for non-metallic pipe surface temperature

A non-metallic tube, surface temperature technology, used in measuring devices, thermometers, measuring heat, etc., can solve the problems of structural strength decline, stability, and not as good as metal pipeline structures, achieve strong ductility and elasticity, reduce measurement errors, prevent broken effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

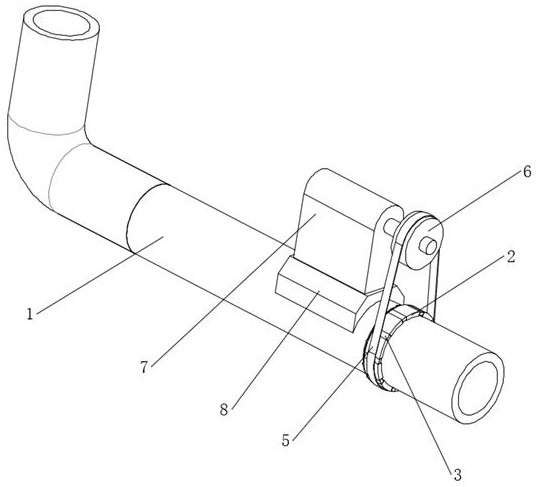

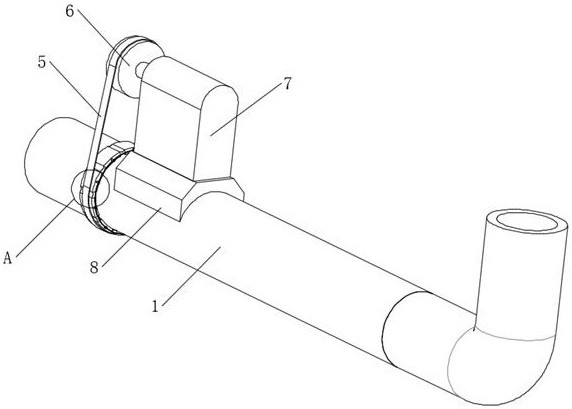

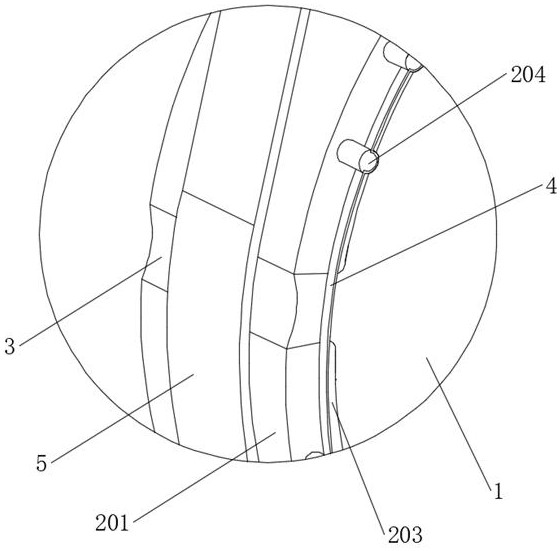

[0041] see Figure 1-4, a non-destructive measurement device for the surface temperature of a non-metallic pipe, comprising a non-metallic pipe main body 1, a temperature-measuring ring is sleeved on the non-metallic pipe main body 1, and the temperature-measuring ring includes a plurality of evenly distributed flexible temperature-measuring blocks 2, two adjacent An elastic connecting belt 3 is connected between the two flexible temperature measuring blocks 2. The flexible temperature measuring block 2 includes a flexible housing 201 with a thermistor 202 installed therein. One end of the flexible housing 201 close to the non-metallic pipe main body 1 is fixedly connected with a temperature measuring plate 203. A pair of terminal posts 204 matching the thermistor 202 are fixedly connected to the outer wall of the flexible shell 201, the thermistor 202 is connected in series between the two terminal posts 204, and a composite cable 4 is connected between the plurality of termin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com