Gypsum board processing and forming system

A technology for processing and forming gypsum boards, which is applied to conveyor control devices, conveyor objects, conveyors, etc., and can solve problems such as scrapping of 90-meter board tails and poor speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

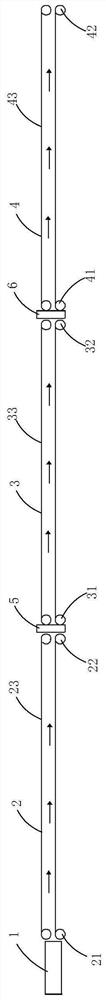

[0014] like figure 1 Distance figure 1 Shows an embodiment in processing gypsum board forming system of the present embodiment. The gypsum board forming system comprising a forming processing station 1, the detection assembly (not shown), a controller (not shown), forming a first conveyor 2, a second forming conveyor 3, forming a third conveyor 4, the first spacer plate 5 and the second spacer plate 6.

[0015] A forming station for gypsum board pressed onto the first conveyor forming conveyor 2 after forming, the gypsum board may be a plaster board. 1 will fall from the forming station plasterboard extruded onto the first forming conveyor 2.

[0016] Forming a first conveyor 2, a second forming conveyor 3, the conveyor 4 forming the third belt conveyor can be both. Forming a first conveyor 2, a second forming conveyor 3, the conveyor 4 forming the third showed a linear strip, which are 90 m length can be. 1 starting from the forming station, forming a first conveyor 2, a second f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com