Waste sorting and recycling device for CNC machining equipment

A processing equipment and recycling device technology, applied in the field of waste sorting and recycling devices, can solve the problems of use, consumption, waste, etc., and achieve the effects of improving completeness, reducing the possibility of residues, and improving the effect of sorting and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

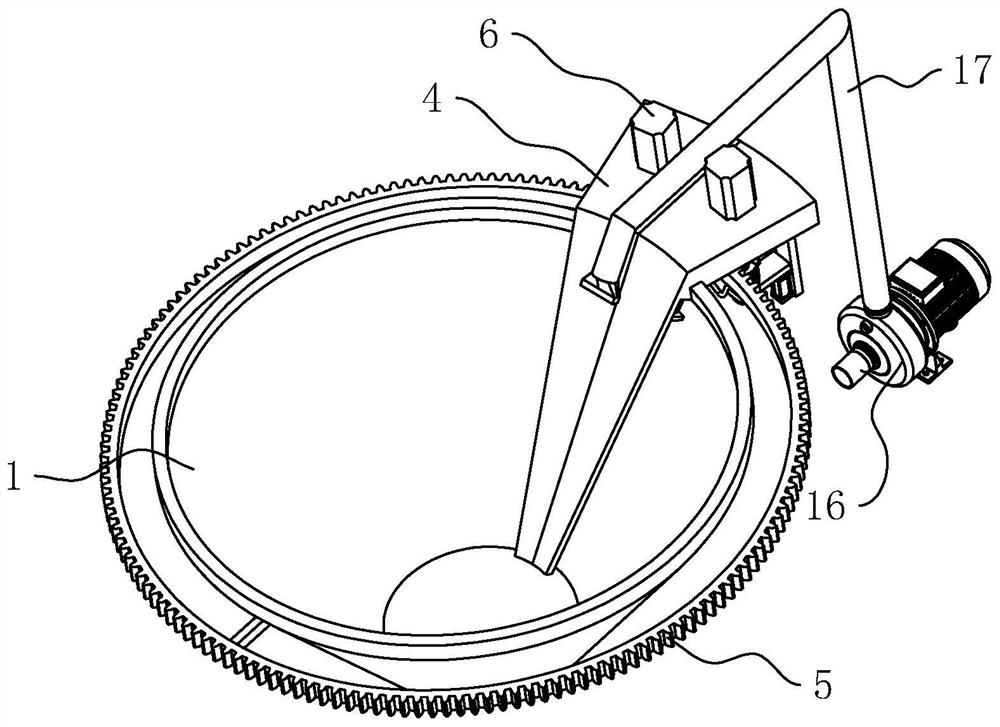

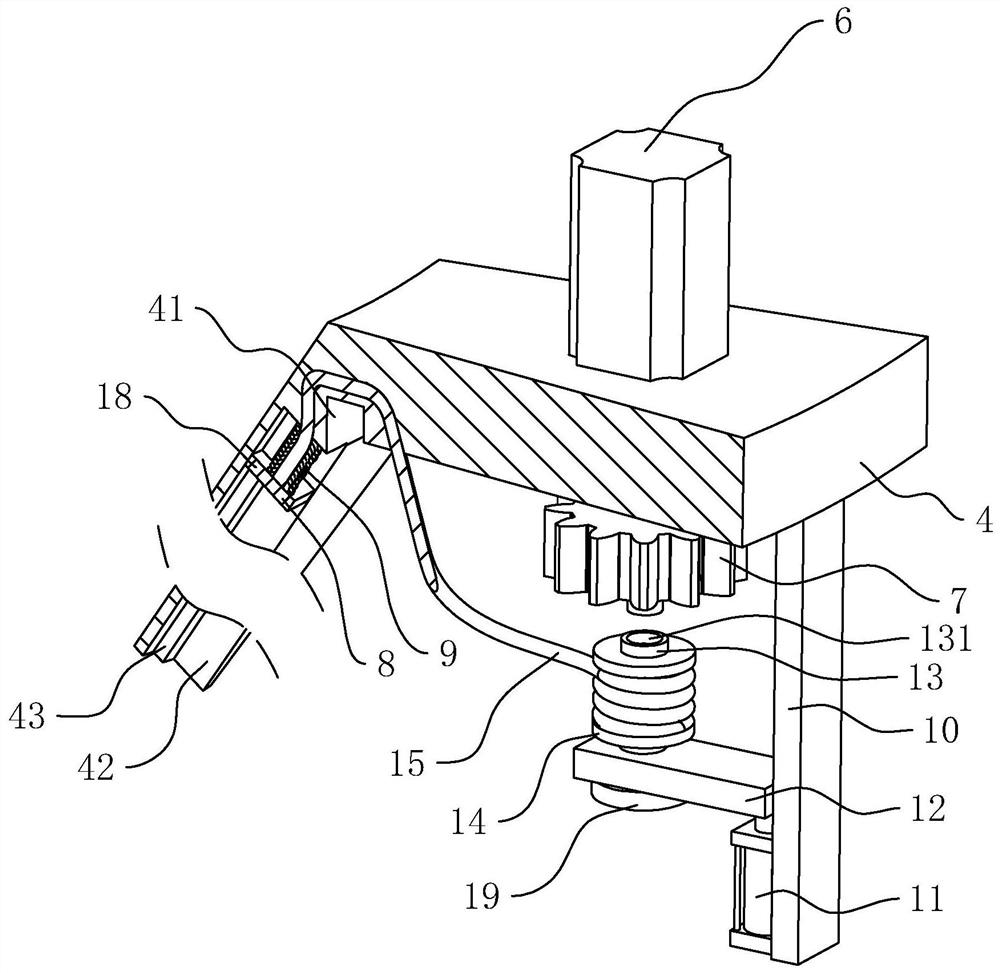

[0034] The following is attached Figure 2-5 The application is described in further detail.

[0035] The embodiment of the present application discloses a waste sorting and recycling device for numerical control processing equipment.

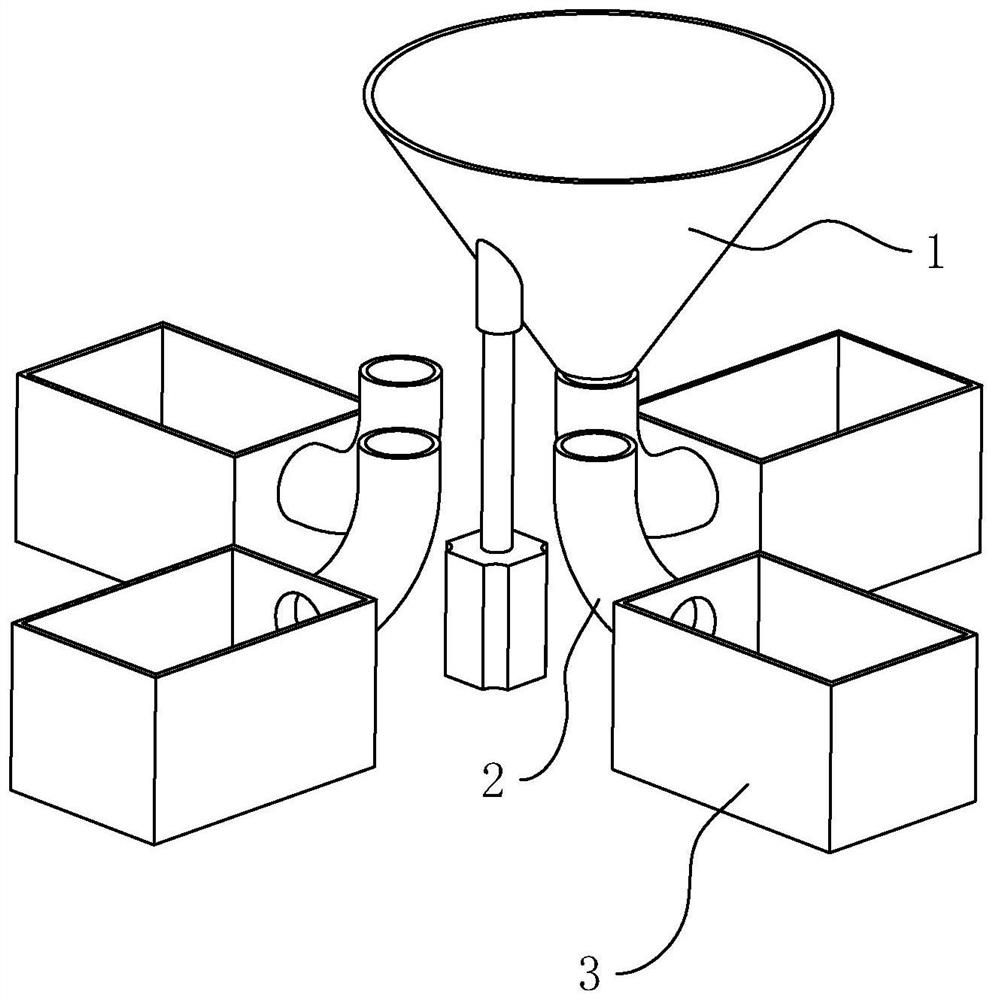

[0036] refer to figure 2 A waste sorting and recovery device for numerical control processing equipment includes a receiving hopper 1 arranged in an inverted conical shape, and the receiving hopper 1 is arranged in a numerical control machine tool for receiving waste generated during processing.

[0037] refer to figure 2 , The hopper 1 is provided with two chip removal mechanisms, and the two chip removal mechanisms are arranged symmetrically with respect to any plane where the axis of the hopper 1 is located.

[0038] At the same time, the hopper 1 is also provided with a driving mechanism for driving the two chip removal mechanisms to move in reverse around the axis of the hopper 1, so that the cooperation of the two chip removal mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com