Heat preservation packaging bag and processing method and processing system thereof

A processing method and technology for packaging bags, which are applied in the field of thermal insulation packaging bags and their processing methods and processing systems, can solve the problem of not being able to maintain a constant temperature of the thermal insulation bag for a longer period of time, and achieve the effects of maintaining temperature, lasting temperature and avoiding dumping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

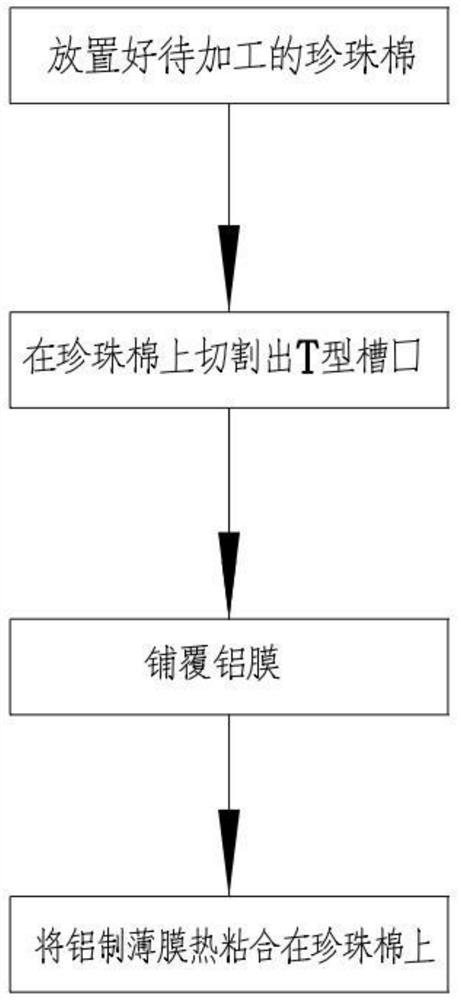

[0038] A method for processing an insulated packaging bag, the method comprising the following steps:

[0039] S1: place the pearl cotton to be processed;

[0040] S2: cutting the pearl cotton with a cutting device, and cutting a T-shaped notch on the top surface of the pearl cotton;

[0041] S3: Lay a thin layer of aluminum film on the pearl cotton, and stick the film on the inner surface of the T-shaped notch through a pressing device;

[0042] S4: thermally bonding the aluminum film to the pearl cotton to make aluminum-coated pearl cotton with notches.

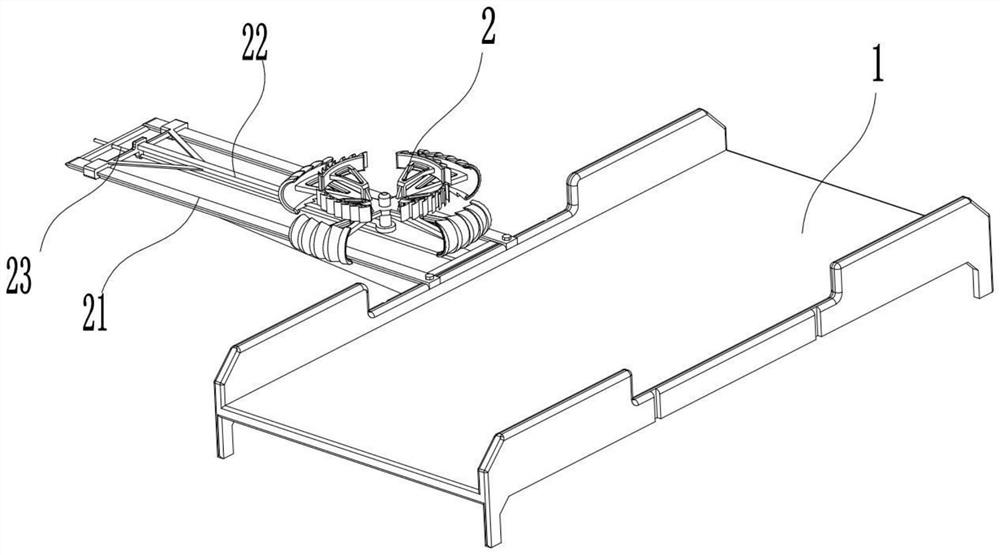

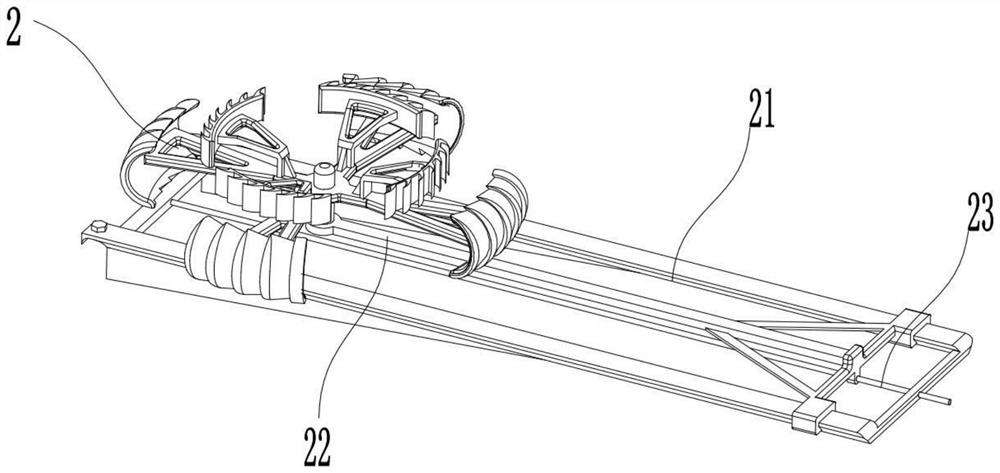

[0043] The embodiment that the present invention cuts notch on pearl cotton is as Figure 1-3 constituted as shown,

[0044] Further, the placement frame 1 is used to place pearl cotton horizontally, and the middle part of the placement frame 1 is fixedly connected with a guide frame 21 by screws. The guide frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com