Cover plate assembly and washing machine

A component and cover plate technology, which is applied in the field of cover plate components and washing machines, can solve the problems that the shaft is exposed when the cover plate is connected with the body, and achieves the effect of ensuring the length and strength and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

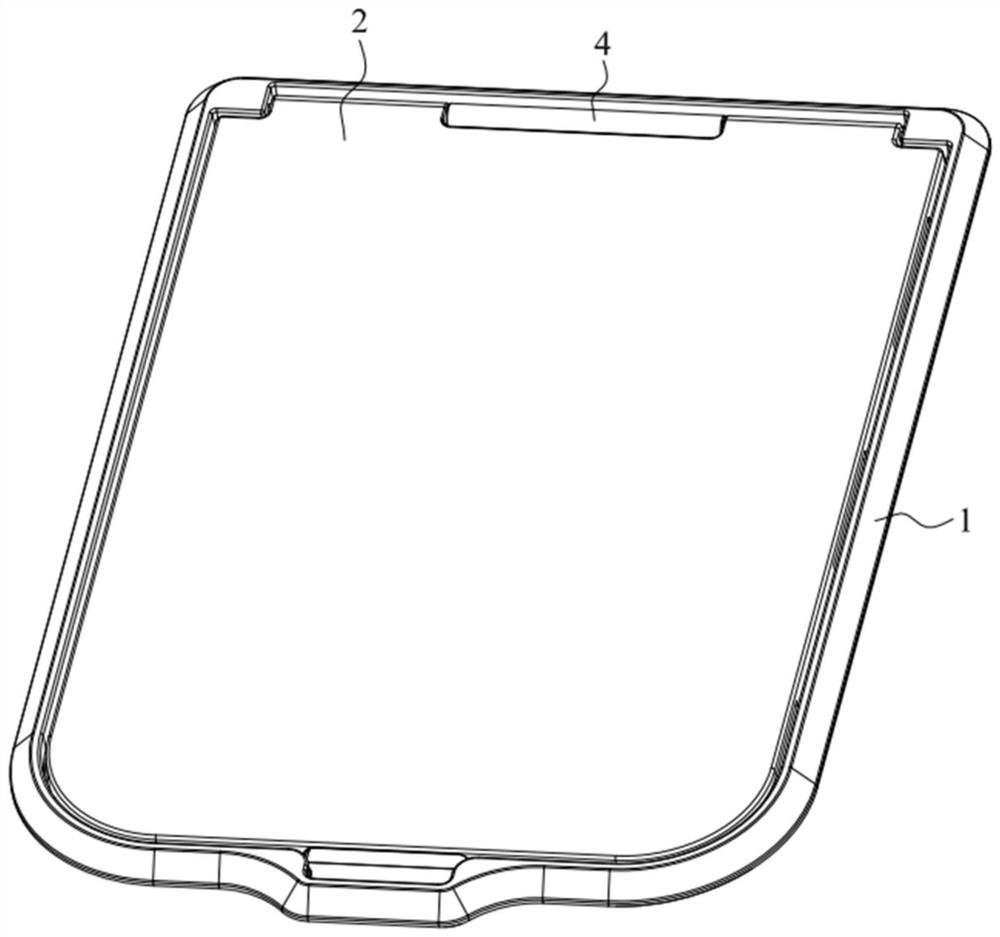

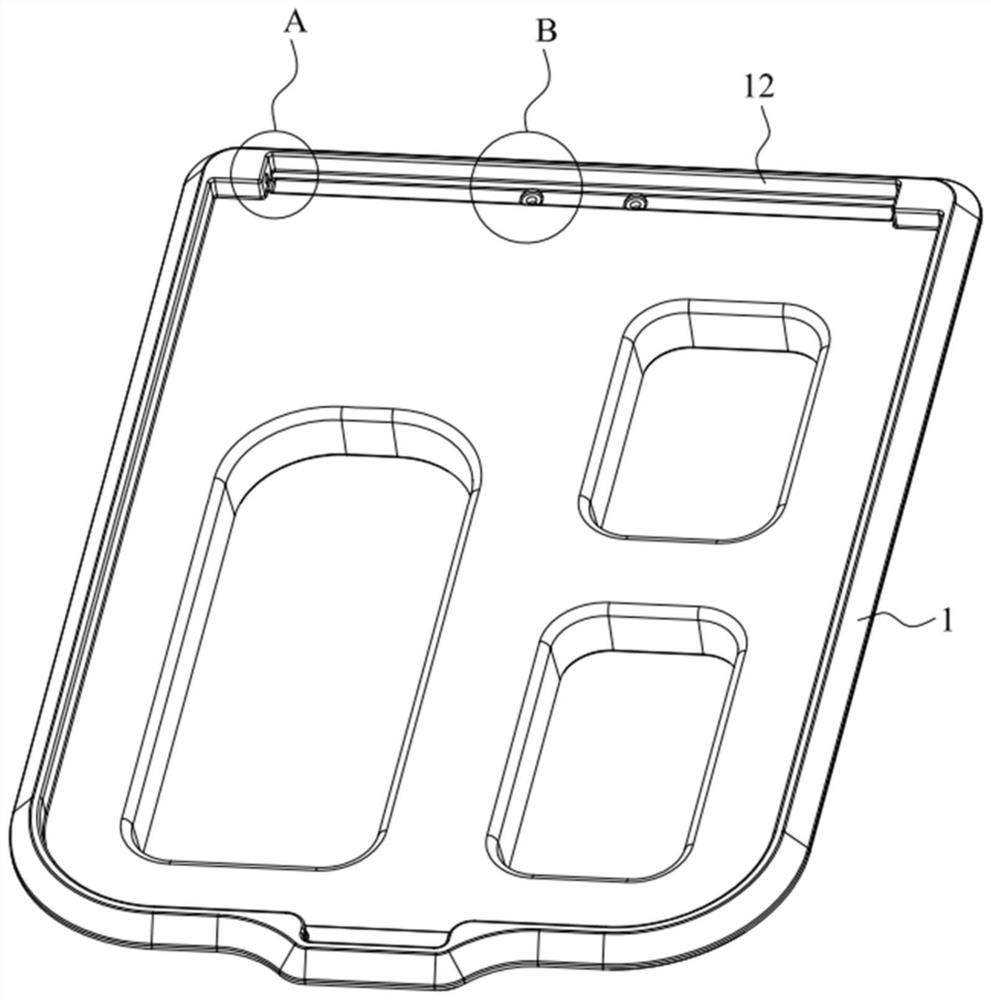

[0043] see Figure 1 to Figure 11 , the embodiment of the present invention provides a cover plate assembly, which can be applied to any opening that needs to be opened and closed, including but not limited to the washing tub, sink and detergent box of the washing machine, and can also be used for boxes, cabinets, etc.

[0044] The cover assembly includes a base 1 and a cover 2 rotatably connected to the base 1 , the cover 2 can open and close the opening on the base 1 . The cover plate assembly also includes a rotating shaft 3 and a shielding cover 4. The rotating shaft 3 is passed through the cover body 2 and the base 1. The shielding cover 4 is detachably connected to the base 1. The shielding cover 4 can axially limit the rotating shaft 3 and shield the rotating shaft 3. .

[0045] The rotating shaft 3 is installed on the cover body 2 and the base 1 to ensure the length and strength of the rotating shaft 3 and prolong the service life of the cover body 2; the shielding co...

Embodiment 2

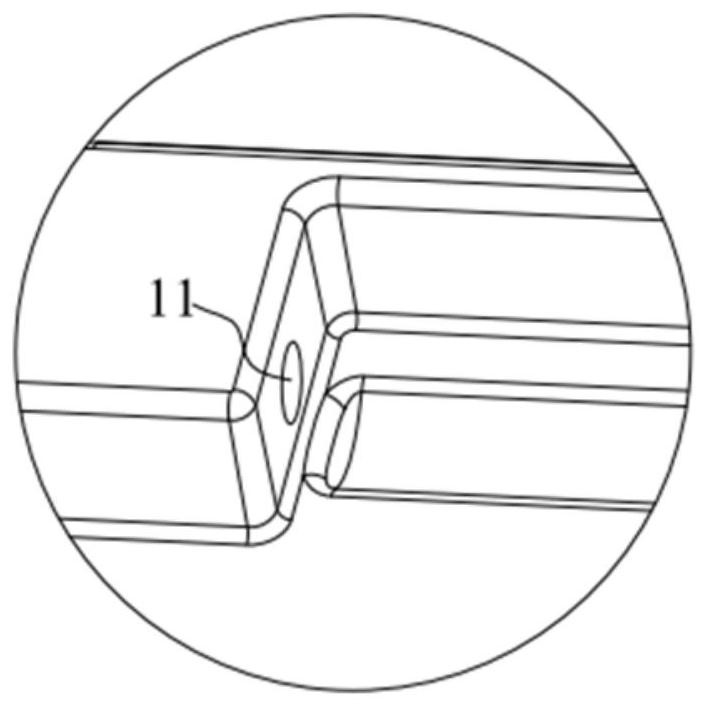

[0063] Figure 12 with Figure 13 Embodiment 2 is shown, in which components identical or corresponding to those in Embodiment 1 are identified with reference numerals corresponding to Embodiment 1. For simplicity, only the differences between Embodiment 2 and Embodiment 1 are described. The difference is that one protrusion 22 is provided. When the cover 2 is connected to the base 1, the protrusion 22 is located in the groove 12, and the extension length of the protrusion 22 is smaller than the extension length of the groove 12, so as to block Cover 4 provides installation space. Only one rotating shaft 3 is needed to connect the cover body 2 and the base 1 , which is convenient to install, ensures the structural strength and shields the rotating shaft 3 .

[0064] During installation, a rotating shaft 3 is passed through the through hole 21 of the raised portion 22, and the raised portion 22 on the cover 2 is placed in the groove 12 on the base 1, so that the through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com